Red Lion TCU User Manual

Cus listed, Model tcu - temperature control unit, Description

1

DSP

PAR

%PW

DEV

MAN

OP1

AL1

AL2

3.60

(91.4)

1.75

(44.4)

(96.5)

3.80

(49.5)

1.95

(137.4)

5.41

(134.4)

5.29

(10.2)

.40

+.6

-.0

+.02

-.00

(45.0 )

1.77

+.03

-.0

+.8

-.00

3.62

(92.0 )

100 msec SAMPLING PERIOD WITH 0.15% ACCURACY

ON DEMAND AUTO-TUNING OF PID CONTROL SETTINGS

DUAL LED DISPLAYS FOR SIMULTANEOUS INDICATION OF

TEMPERATURE AND SETPOINT, SECOND ANALOG INPUT OR

HEATER CURRENT

ACCEPTS 10 DIFFERENT TYPES OF SENSOR INPUTS

(Thermocouple or RTD)

SELF-DIAGNOSTICS

FULL PID CONTROL WITH REDUCED OVERSHOOT

OPTIONAL RS485 SERIAL COMMUNICATIONS INTERFACE

OPTIONAL DUAL ALARM OUTPUTS (USES OUTPUT MODULES)

OPTIONAL COOLING OUTPUT (USES OUTPUT MODULE)

OPTIONAL LINEAR 4 to 20 mA or 0 to 10 VDC OUTPUT FOR

CONTROL OR TEMPERATURE RE-TRANSMISSION

OPTIONAL HEATER CURRENT MONITOR AND BREAK ALARM

OPTIONAL MOTORIZED VALVE POSITION CONTROL AND

VALVE FAIL ALARM

OPTIONAL SECOND ANALOG INPUT FOR REMOTE SETPOINT

AND CASCADE CONTROL

OPTIONAL TYPE 4X/IP65 SEALED FRONT BEZEL

STATUS INDICATORS FOR OUTPUTS AND CONTROL MODES

PROGRAMMABLE USER INPUT (DIGITAL) FOR ADDED

FLEXIBILITY

SENSOR ERROR COMPENSATION (Slope and Offset) AND

BREAK DETECTION

MANUAL/AUTOMATIC AND LOCAL/REMOTE SETPOINT

CONTROL MODES

SETPOINT RAMPING FOR PROCESS STARTUP

PARAMETER SECURITY VIA PROGRAMMABLE LOCKOUTS

FIELD REPLACEABLE AND INTERCHANGEABLE OUTPUT

MODULES (Relay, Logic/SSR Drive and Triac)

DESCRIPTION

The TCU Controller accepts signals from a variety of temperature sensors

(thermocouple or RTD elements), precisely displays the process temperature,

and provides an accurate output control signal (time proportional or linear) to

maintain a process at the desired control point. A comprehensive set of easy to

use steps allows the controller to solve various application requirements.

The controller can operate in the PID control mode for both heating and

cooling, with on-demand auto-tune, which will establish the tuning constants.

The PID tuning constants may be fine-tuned by the operator at any time and then

locked out from further modification. The controller employs a unique overshoot

suppression feature, which allows the quickest response without excessive

overshoot. The unit can be transferred to operate in the manual mode, providing

the operator with direct control of the output. The controller may also be

programmed to operate in the ON/OFF control mode with adjustable hysteresis.

Dual 4-digit displays allow viewing of the process temperature and setpoint

simultaneously. Front panel indicators inform the operator of the controller and

output status. Replaceable and interchangeable output modules (relay, SSR

drive, or triac) can be installed for the main control output, alarm output(s) and

cooling output.

Optional dual alarms can be configured to activate according to a variety of

actions (Absolute HI or LO, Deviation HI or LO, Band IN or OUT, Heater

Break and Valve Fail Detect) with adjustable hysteresis. A standby feature

suppresses the output during power-up until the temperature stabilizes outside

the alarm region. An optional secondary output is available (for processes that

require cooling) which provides increased control accuracy and response.

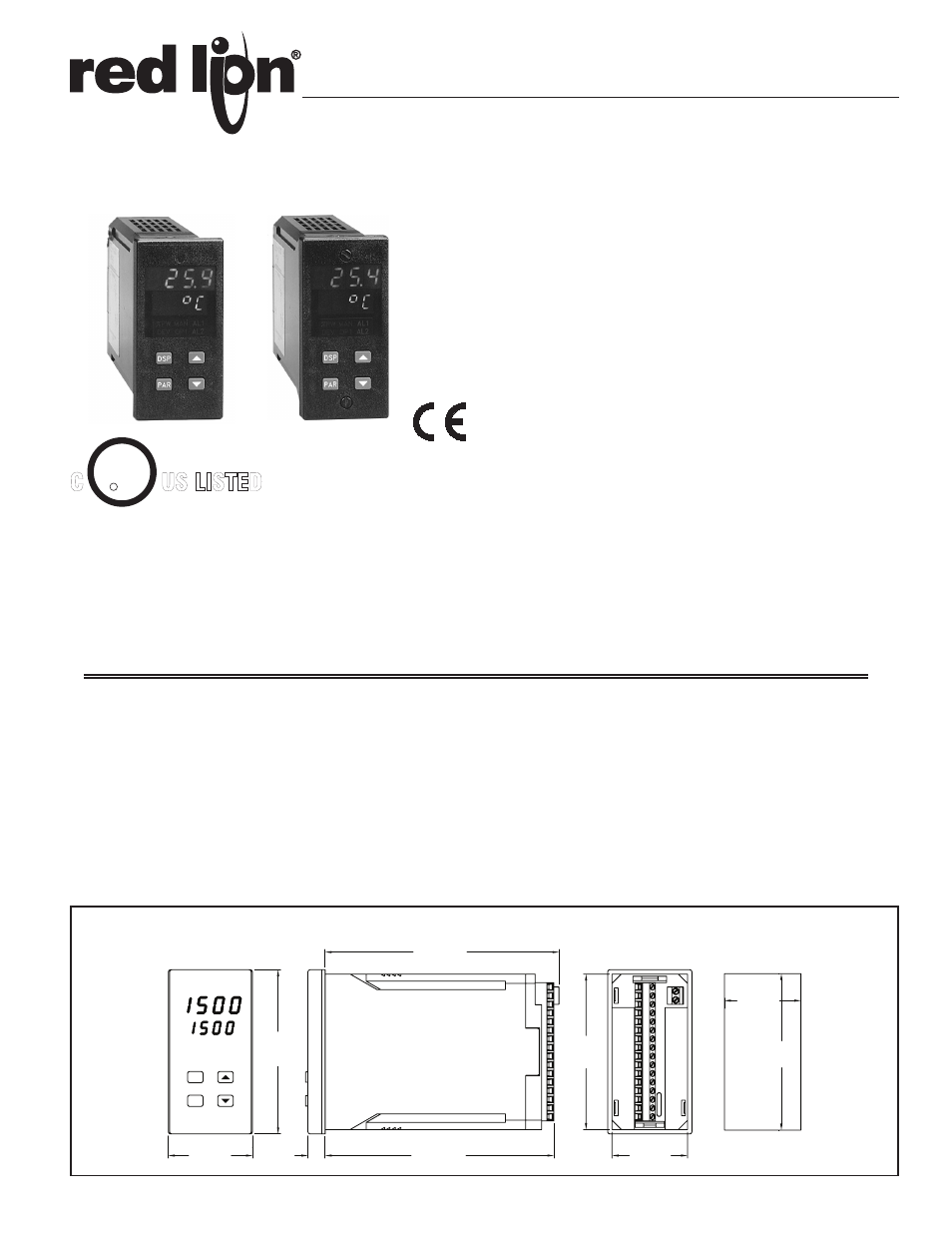

MODEL TCU - TEMPERATURE CONTROL UNIT

DIMENSIONS In inches (mm)

Note: Recommended minimum clearance (behind the panel) for mounting clip installation is 5.5" (140) H x 2.1" (53.4) W.

Bulletin No. TCU-H

Drawing No. LP0314

Released 08/13

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

www.redlion.net

1

C

US LISTED

UL

R

51EB

IND. CONT. EQ.

PANEL CUT-OUT