Profibus, Fieldbus module profibus, Configuration – Burkert Type 8645 User Manual

Page 125: Commissioning english, Config�uration

CommissioninG

English

8645 - 125

PROFIBuS

®

The task of the bus system is to provide a high-speed serial connection between the decentralised periphery

and the central master (controller). In addition to the input and output data, parameter, configuration and dia-

gnositc data are also transmitted.

The PROFIBUS

®

-DP is defined in accordance with DIN 19245 Part . Many PROFIBUS

®

masters (control-

lers) require a configuration program with which the network structure is described. These programs require

the device data base file (DDB file). It contains bus-specific data.

Data from the pROFIbuS

®

-Dp (excerpt)

Available baud rates

9.6 / 19.2 / 45.45 / 9.75 / 187.5 / 500 kBaud

1.5 / / 6 / 12 MBaud

Manufacturer number

0949 h

Data volume without RIO expansion

max. 2 input and 2 output bytes

Data volume with RIO expansion / intermediate module

max. 2 input and 2 output bytes per expansion

Fieldbus Module PROFIBuS

®

All plug connections (voltage, bus) and the pneumatic connections must be made before commissioning.

In addition, the bus address must be set.

NOTE!

For further details, please refer to chapter

Configuration and Function of the Modules.

config�uration

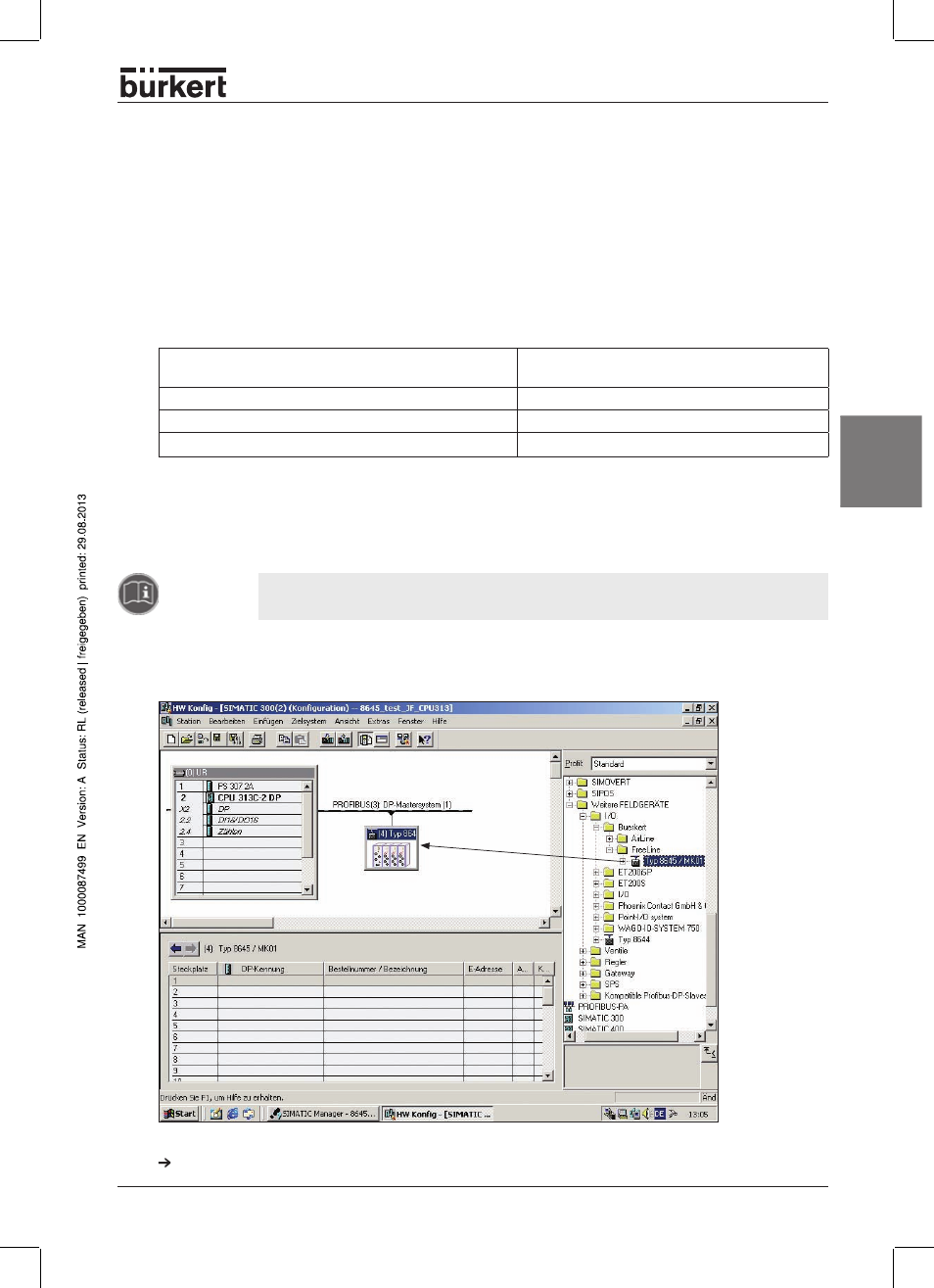

The configuration procedure is described here using the example of the STEP 7 (Siemens).

Illustration: Overview

Pull out the slave, Type 8645/MK01, from the bus strand (drag and drop).