Instrument configuration, Dual speed filler/fill proof menu, Fill proof menu – Hardy HI 3010 Filler/Dispenser Controller User Manual

Page 46: Adjust ingredient/ingredient 1 set to flour, Setting parameters for ingredient 2

HI-3010 Filler/Dispenser/IBC

30

Service Manual

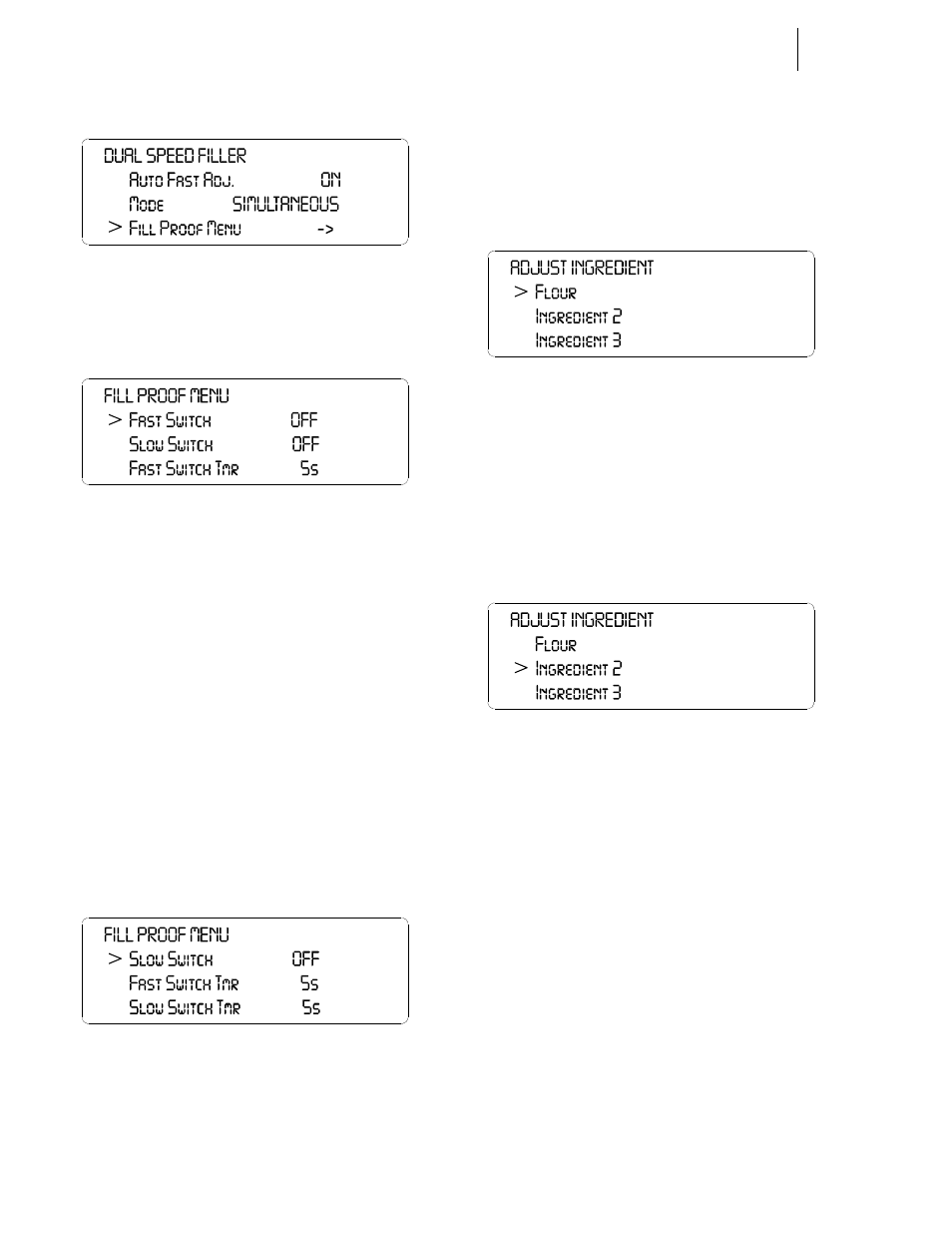

FIG. 4-36 DUAL SPEED FILLER/FILL PROOF MENU

5.

Press the Enter button, the Fill Proof

Menu appears. (See Fig. 4-37)

FIG. 4-37 FILL PROOF MENU

6.

Set the Fast Switch - Press the right or

left arrow buttons to toggle between

OFF and ON.

7.

Press the down arrow until the cursor

is in front of Slow Switch.

8.

Set the Slow Switch - Press the right

or left arrow buttons to toggle

between OFF and ON.

9.

Press the down arrow until the cursor

is in front of Fast Switch Tmr (Timer).

10. Press the right or left arrow buttons to

increase or decrease the Fast Switch

Timer. This is the time you want the

Fast Switch to remain on.

11. Press the Enter button to set the entry.

12. Press the down arrow until the cursor

is in front of Slow Switch Tmr

(Timer). (See Fig. 4-38)

FIG. 4-38 FILL PROOF MENU

13. Press the right or left arrow buttons to

increase or decrease the Slow Switch

Timer. This is the time you want the

Slow Switch to remain on.

14. Press the Enter button to set the entry.

15. Press the Exit button to return to the

Dual Speed Filler Menu.

16. Press the Exit button to return to the

Adjust Ingredient 1 Menu. (See Fig.

4-39)

FIG. 4-39 ADJUST INGREDIENT/INGREDIENT 1

SET TO FLOUR

Step 3. If this is the only ingredient you are configuring,

press the Exit button to return to the Configuration

Menu.

Step 4. If there are more ingredients used in this process, or

you want to set up ingredients for other processes,

press the down arrow until the cursor is in front of

Ingredient 2. (See Fig. 40)

FIG. 4-40 SETTING PARAMETERS FOR

INGREDIENT 2

Step 5. Press the Enter button and repeat the configuration

process until you have configured all the ingredi-

ents you want for your process(es). You can set up

to 12 ingredients.

Instrument Configuration

The Instrument Configuration process sets up the instrument

to operate as a scale and the setup for the operating parame-

ters required for your filling/dispensing process. This

includes setting WAVERSAVER

®

, Scale Capacity, Units of

Measure, Motion tolerance and other instrument parameters

required for your Filling/Dispensing process. Here is where

the permanent parameters are entered. All the parameters

configured except the communications parameters, (IP

Address etc.) are stored in the Secure Memory Module

(SMM).