J - electrical inspection – Hardy HI 3010 Filler/Dispenser Controller User Manual

Page 124

HI-3010 Filler/Dispenser/IBC

108

Service Manual

J - Electrical Inspection

J

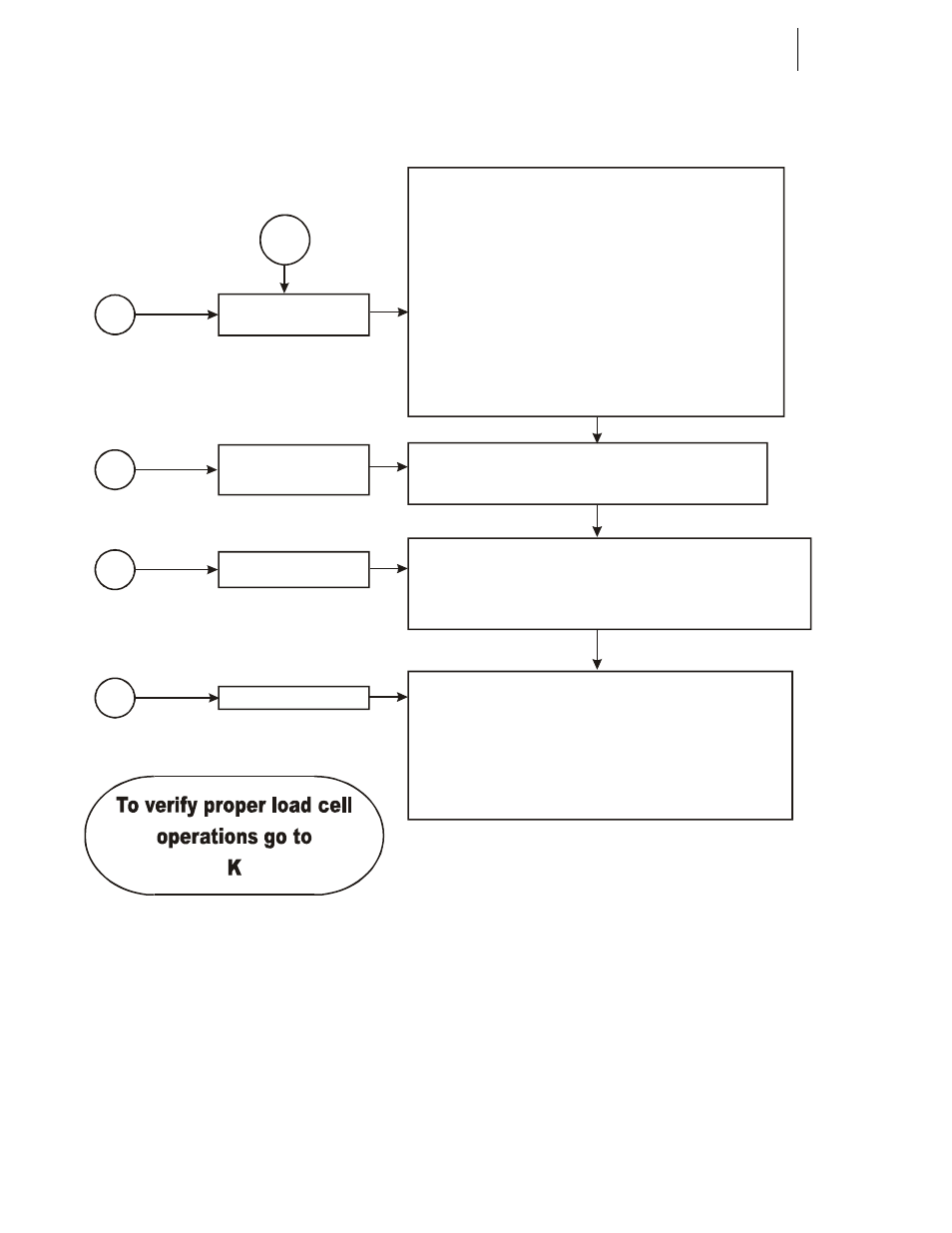

J1

1) Verify the front display illuminates.

2) Completes the Initialization process.

3) Displays a weight reading. This weight value will not be

correct if a calibration procedures were not performed.

Apply weight to the vessel

a) Does the weight increase and decrease in the

correct direction with the weight?

B) Is the weight reading repeatable?

C) The weight value will not be correct until a proper

calibration is completed.

1) Verify color code, input is excitation, Output is signal.

2) Shielding

a) Grounded only at the controller

b) Continuous shield connection from the load cell cable

to the instrument. Single point EMI/RFI drain.

c) Terminated but not grounded, at the summing box.

3) Sense lines Installed?

A) Jumpers or sense lines in the J1 connector?

B) Sense lines must be installed for C2 calibration.

4) Using a multimeter verify readings.

Verify the proper

voltage level has been

supplied.

J2

Apply power to the

controller only if supply

voltage is correct.

J3

Does the scale reflect

a weight change?

J4

Cabling

DO NOT POWER UP THE CONTROLLER UNTIL

INPUT VOLTAGES CAN BE VERIFIED!

1) Check the specification label attached to the weight controller

chassis. (110 VAC/220 VAC or 24 VDC)

2) Use a meter to verify neutral, ground and Hot are proper.

3) Computer grade power

4) Use active filters for motor noises and spikes.

5) Use isolation transformers to combat surges and sags.

6) Isolated from SCR and motor control circuits

7) Use a common earth ground.

a) Keep ground cable runs as short as possible

b) Excessive ground cable runs can act as an antenna

for AC noise.

c) Install grounding straps around load cells to direct

static away from the load cell and directly to ground.

d) Install ground straps on the input and discharge

piping, and the vessel to a common earth ground