K - load sharing and load sensor checkout, 109 chapter 7 troubleshooting – Hardy HI 3010 Filler/Dispenser Controller User Manual

Page 125

109

CHAPTER 7

Troubleshooting

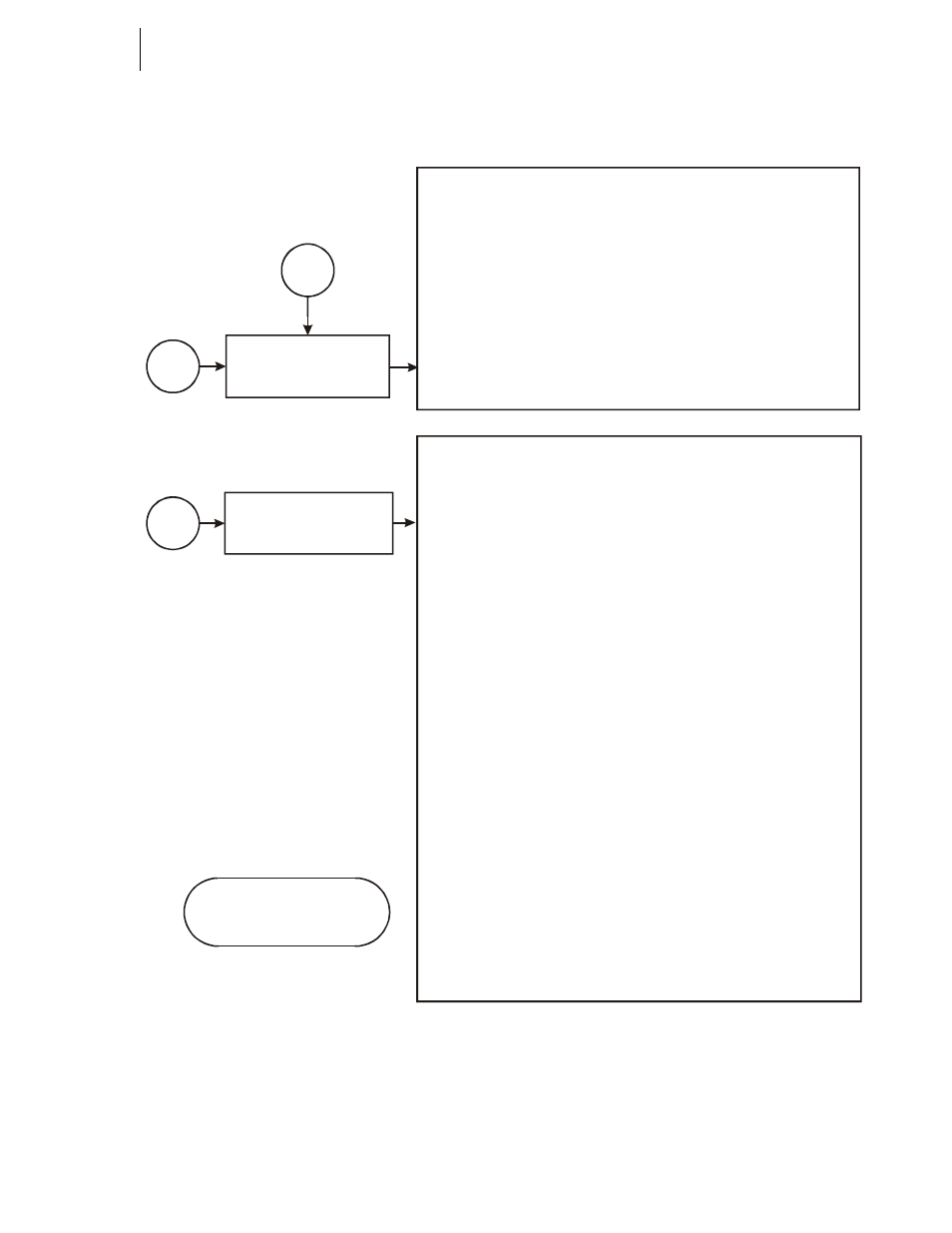

K - Load Sharing and Load Sensor Checkout

Monitor system for proper

operation

Check out complete

K

Verify the proper

voltage level has been

supplied

K1

A pply power to the

controller only if supply

voltage is correct.

K2

1) Does the mV signal increase in a positive

direction?

2) If you receive a negative result, check if load cell

is mounted correctly.

a) The arrow goes with the direction of the force.

b) If there isn’t an arrow, you must manually verify the

correct direction. A negative reading indicates the

load cell is upside down.

c) Load cells in tension will not reflect a negative reading

if installed upside down. If upside down, only the

force applied by the cable would be included in the

weight readings.

D) If you are still receiving a negative signal, verify the

Load cell wire color code.

1) Verify a positive reading from each load cell, using a multi

meter.

2) Record the mV reading and compare each corner for proper load

sharing.

a) Proper load sharing should see only a difference of +/- .5 mV.

b) Larger differences due to motors and piping, should not

exceed +/- 4 mV.

c) If there aren’t any motors, valves or piping to explain the mV

difference, adjust the corners and balance the MV readings.

D) Use shims or if equipped adjusting bolts on the load cell

Mounting Hardware.

E) Drawing a load cell map will help determine the correct

leg to adjust and in which direction.

Three Load Cells Balance Like a Three Legged Chair

1) Using a spirit level, verify the vessel is vertically and horizontally

correct.

2) Verify if any height change effects the attitude of adjacent

vessels or piping.

3) Adjust each leg to dynamically match mV outputs.

4) Verify the mV readings and physical level when complete.

Four Load Cells or More Present a Challenge

1) Use a multi meter:

Determine the sum of the load cell signals and

Your target mV setting for each load cell.

2) Read the output of individual load cells.

3) Adjust the load cell with the lowest reading to dynamically

match the target mV readings obtained in step 1.

4) Read the mV readings from each load cell to verify proper

correction.

5) Repeat steps 3 and 4 to achieve a proper load sharing vessel.

6) Verify the mV readings and vessel level when complete.