Jb hi 3000-rc -pb -ac -rio, Smart diagnostics (-sd), Fig. 1-5 smart diagnostics card – Hardy HI 3010 Filler/Dispenser Controller User Manual

Page 20

HI-3010 Filler/Dispenser/IBC

4

Service Manual

teristics of each individual load sensor and detects the quan-

tity of load sensors in the system. Calibration is performed

by simply adding a reference point from the front panel or

via the Web Server. The reference can be zero (no weight on

the scale) or alternatively, a known weight on the scale. The

instrument is capable of performing traditional calibration

such as with the use of certified test weights.

NOTE:

WAVERSAVER

®

and C2

®

are registered trade-

marks of Hardy Instruments Inc.

On-Board Diagnostics

The HI 3010 has a built in diagnostics utility which enables

the operator to rapidly troubleshoot a weighing system from

the front panel of the controller or via the Web Server. Sim-

ply press the Test button and scroll through several tests that

will furnish the current state of each of the parameters that

concern your application and the weigh system. Help is just

a click away in the event you should not understand the

information on the display or need a description of the

parameter.

Secure Memory Module (SMM)

The Secure Memory Module stores critical configuration (up

to 12 material configurations), calibration and setup data of

the HI 3010 Filler/Dispenser/IBC, thereby protecting this

information from corruption. During system operation when

a new parameter is entered, the SMM automatically updates

the value in its memory. Data stored in one HI 3010 can be

restored in another HI 3010 by physically transferring the

SMM to the new instrument. The SMM is conveniently

accessible from the instruments rear panel.

Relays

The HI 3010 has four standard AC solid-state electronic

relays that can be used to open or close valves or gates or

turn motors, mixers, vibration equipment, heaters, coolers,

etc. on or off

Serial Port

One standard RS 232 serial port which can be configured to

transmit weight data to a serial printer. Baud rates are user

selectable at 600, 1200, 2400, 4800, 9600 or 19,200.

Options

-JB

Enables the instrument to sum four load sensor inputs to act

as a built-in summing box.

HI 3000-RC

Rear cap for the HI 3000 Series controllers. Upgrades the

entire assembly to a NEMA 4X rating by enclosing all the

rear panel connectors.

-PB

Profibus interface allows instrument capabilities to be com-

municated remotely to and from a Siemens or other Profibus

compatible processor.

-AC

AC input power for the HI 3000 Series remote mount instru-

ment to act as a booster power supply for multiple instru-

ments on Devicenet.

-RIO

Allen-Bradley Remote I/O interface allows full instrument

capabilities to be communicated remotely to and from an

Allen-Bradley processor.

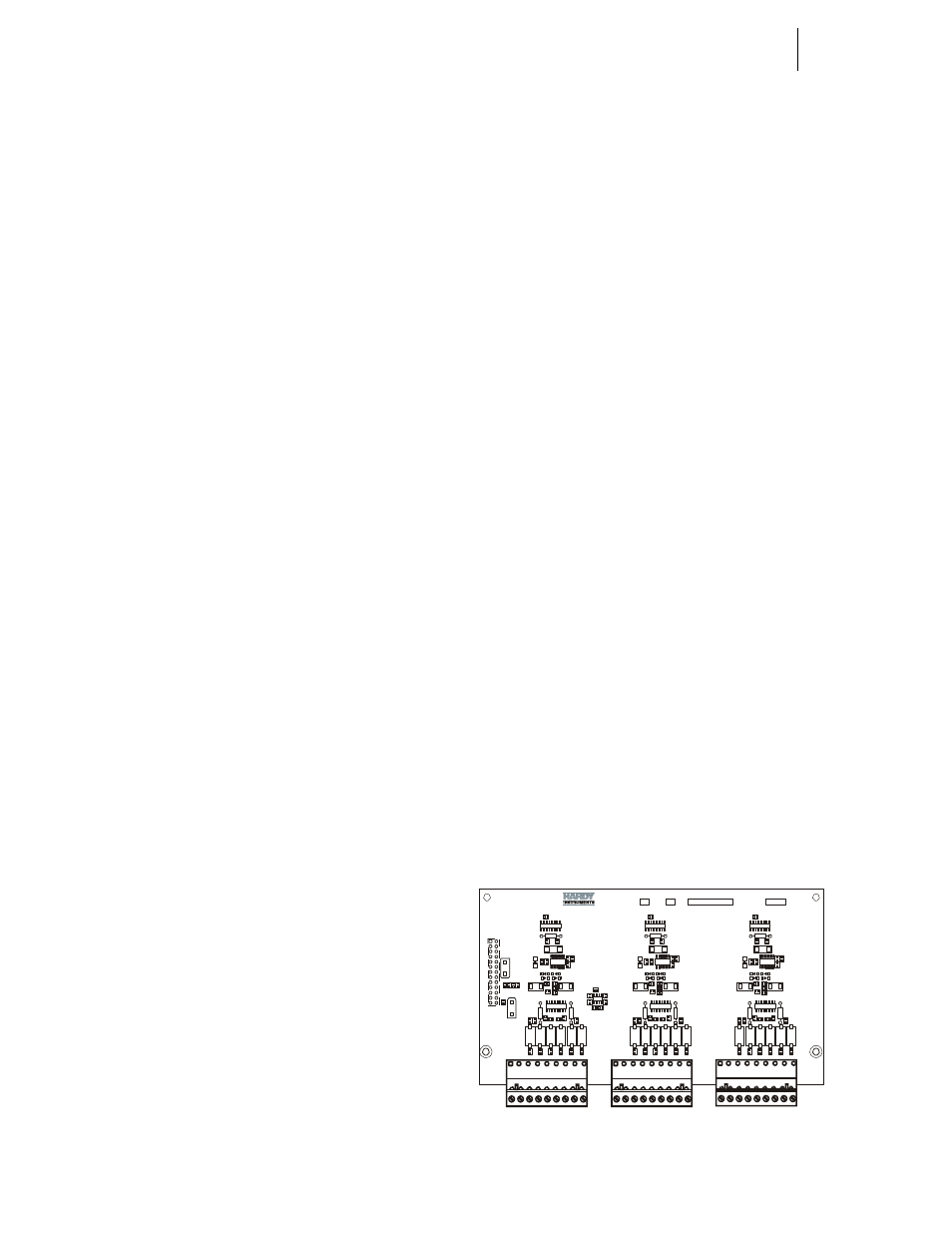

Smart Diagnostics (-SD)

Smart Diagnostics consists of a daughter card (See Fig. 1-5)

and rear panel that is attached to the main board in all instru-

ments. The Smart Diagnostics card enables the user to attach

three (3) additional load cells to the HI 3000 Series instru-

ment for a total of four. This option enables the user to:

•

Read individual C2 load Sensor certifica-

tion data

•

Perform a Stability Test

•

Display load sensor weight and voltage

readings from the front panel and web

•

Perform a return to Zero test

•

Set Factory Defaults

•

From the Front Panel or Web Page, turn

On/Off individual load sensors and dis-

plays individual weights, mV/V (milli-

volts/volt) and mV (millivolts).

To get price and availability for the Smart Diagnostics

option, contact your local Hardy Representative or the Hardy

Service Center.

FIG. 1-5 SMART DIAGNOSTICS CARD

SMART DIAGNOSTICS PWA

0535-0502-

REV

SN

OPTION