About solid state relays with light loads, Diagnostics, Scr switching load circuit – Hardy HI 3010 Filler/Dispenser Controller User Manual

Page 143: Operation/diagnostics, Set factory defaults

127

CHAPTER 7

Troubleshooting

Step 5. Press the Exit button until you return to the Standby

Display.

Using Solid State Relays with Light Loads

(Optional Set Relays)

About Solid State Relays With Light Loads

There have been installations where solid state relays have

been used and failed to shut off a solenoid or relay when de-

energized. The actual problem comes from the internal snub-

bing network in parallel with the Silicon Controlled Rectifier

(SCR) which does the actual switching. This network pre-

sents an impedance of 30K ohms, which means with 120

volts across, it will pass 4mA of AC current.

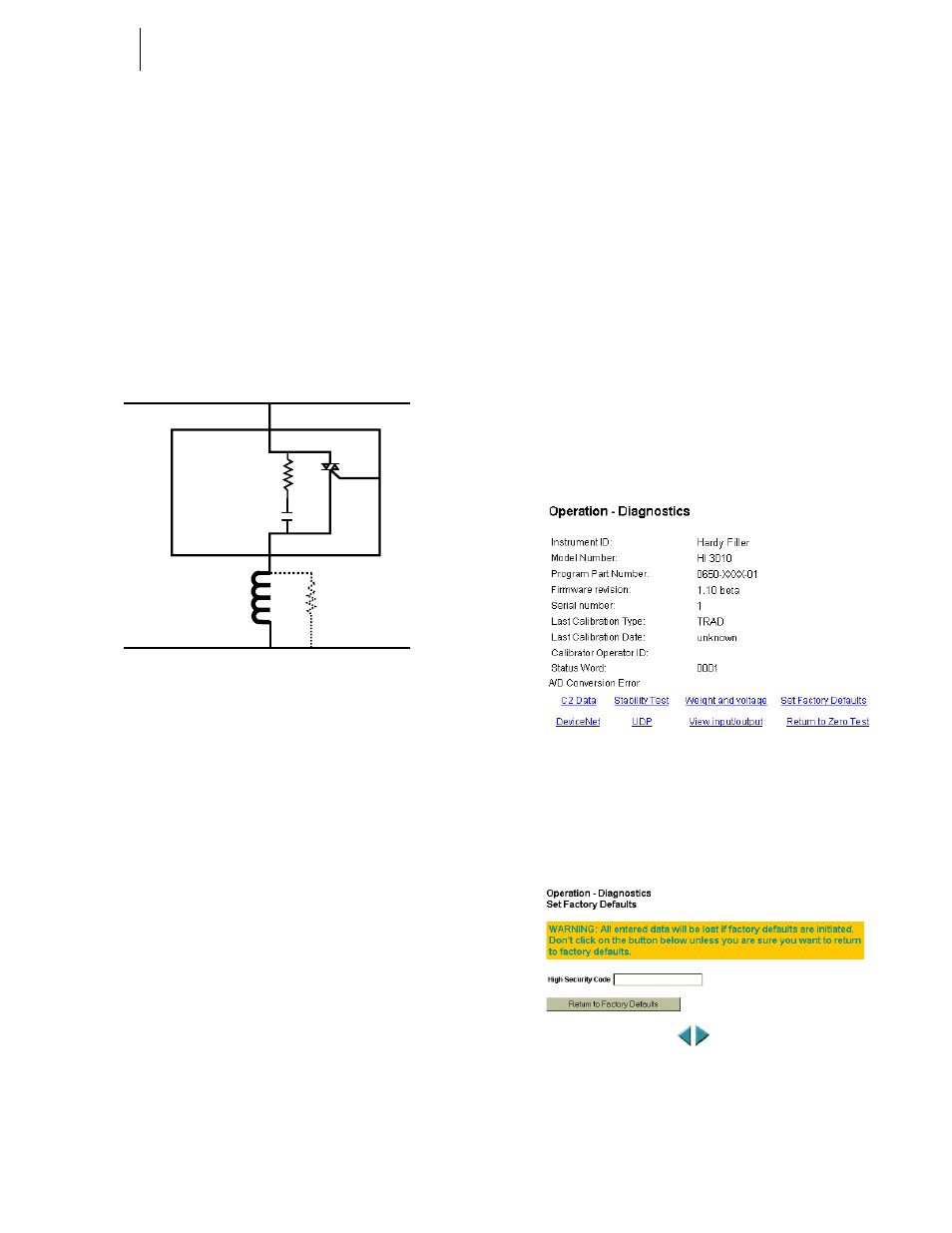

FIG. 7-97 SCR SWITCHING LOAD CIRCUIT

1.

The SCR itself presents no leakage

current. Some solid state relay manu-

factures specify 20mA minimum

load. This is based on the presumption

a relay or solenoid will drop out with

only 4mA through it, which is not

always true. That may not be true.

When switching a light load with a

solid state relay across the line, you

must look at the rated drop-out current

of the load, and if it is less than 4mA

it may not turn off. The solution is to

put a loading resistor in parallel with

the light load, to be sure leakage cur-

rent is sufficiently shunted away from

the coil.

2.

Assume a load like a relay with a coil

of 15,000 ohms and of 5% of nominal

drop-out. When the solid state relay is

off, there will still be 1/3 of the line

voltages across the relay, so it will not

drop out. For the relay to have 5% of

the line across it, it and a parallel

shunt resistor must be 20 times less

resistance than the 30K snubbing net-

work, or 1.5K ohms. Use less than a

1.67K ohm parallel resistor and now

total load is below 1.5K ohm or

80mA.

System Integrity Check and Fault Determi-

nation From the Web Browser

Diagnostics

Diagnostics is used to troubleshoot the Filler/Dispenser. A

complete Troubleshooting Guide is available in the Service

Manual. What is important for Operational purposes is to be

able to see the information about this instrument. (See Fig. 7-

98)

Setting Default Settings is also useful to operators.

Step 1.

Click on Diagnostics. The Diagnostics Page

appears. (See Fig. 7-98)

FIG. 7-98 OPERATION/DIAGNOSTICS

Step 2.

Click on “Set Factory Defaults”. The Set Factory

Defaults page appears. (See Fig. 7-99)

FIG. 7-99 SET FACTORY DEFAULTS

WARNING:

ANY

AND

ALL

DATA

WILL

BE

LOST

IF

FAC

-

TORY

DEFAULTS

ARE

INSTALLED

.

THIS

,

INCLUDES

EVERY

PARAMETER

THAT

WAS

CHANGED

FOR

INGREDIENTS

, IP

SOLID

STATE

RELAY

HOT

NEEDED

SHUNT

15000 ohm

RELAY

COIL

NEUTRAL