Protective functions – Panasonic MINAS E-series User Manual

Page 154

154

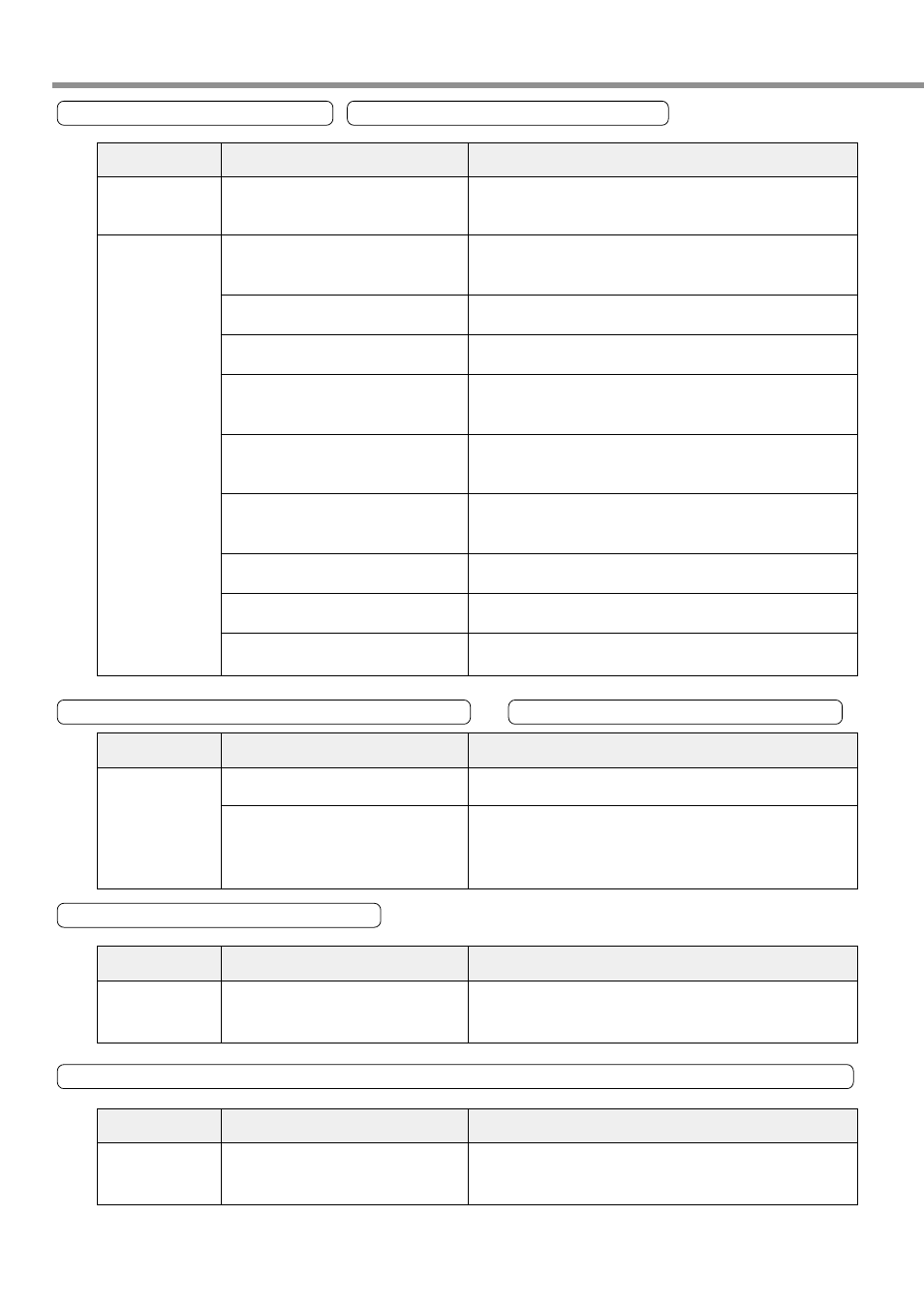

Protective Functions

Overshooting/Undershooting The motor is overheated (burnout)

Category

Adjustment

Installation

Cause

Gains are poorly adjusted.

Load inertia is high.

The equipment (machine) has play and

slip.

Ambient temperature and environment

The cooling fan stops. The air intake of

the fan is dirty.

Mismatch between the driver and motor

The motor bearing is defective.

The electromagnetic brake keeps on

running (failure to release the brake).

The motor is defective (due to oil,

water, etc.)

With the dynamic brake activated, the

motor is rotated by external force.

Action

Check gains using the waveform graphic function of

PANATERM

®

. Correctly adjust gains. Refer to Section on

Adjustment.

Check gains using the waveform graphic function of

PANATERM

®

. Increase capacity of the motor and driver and

decrease inertia ratio. Use reduction gears.

Modify coupling with the equipment (machine).

If the ambient temperature exceeds a specified value, install the

cooling fan to reduce the temperature.

Inspect the cooling fans of the equipment and the driver. As the

latter needs to be replaced, ask for repair.

Check the nameplates of the driver and motor. Referring to the

instruction manuals or catalogs, select a correct combination of

them.

Power off, turn the shaft of the motor independently, and check

if there is any rumbling sound. If so, replace the motor. Ask for

repair.

Check voltage of the brake terminal. Apply power (DC24V) to

the power supply and release the brake.

Avoid high temperature/humidity, oil, dust, and iron powders.

Check the operating pattern, use condition, and working

condition, and avoid this kind of operation.

Parameter returns to the last value

When using PANATERM

®

, the message “communication port or driver cannot be detected” appears

The speed (movement) is large or small

Rotation speed does not increase to the set speed

Category

Adjustment

Cause

The position loop gain is low.

The dividing/multiplier are not

appropriate.

Action

Adjust the value of the position loop gain Pr10 to approximately

100.

Correct the values of the numerator of 1st command pulse ratio

Pr46, multiplier of numerator of command pulse ratio 4A, and

denominator of command pulse ratio 4B. Refer to parameter

settings of each mode.

Category

Parameter

Cause

A parameter value has not been written

into EEPROM prior to power-off of the

driver.

Action

Refer to Writing to EEPROM of “Structure of Each Mode” on

Page 50 of Preparation edition.

Category

Wiring

Cause

The connector CN X6 is not connected

to the personal computer through the

communications cable (RS232C).

Action

Connect the communications cable (RS232C) to the connector

CN X6. Check that the communications cable is disconnected.