Trouble case, Original position varies, The motor has abnormal sound or vibration – Panasonic MINAS E-series User Manual

Page 153

153

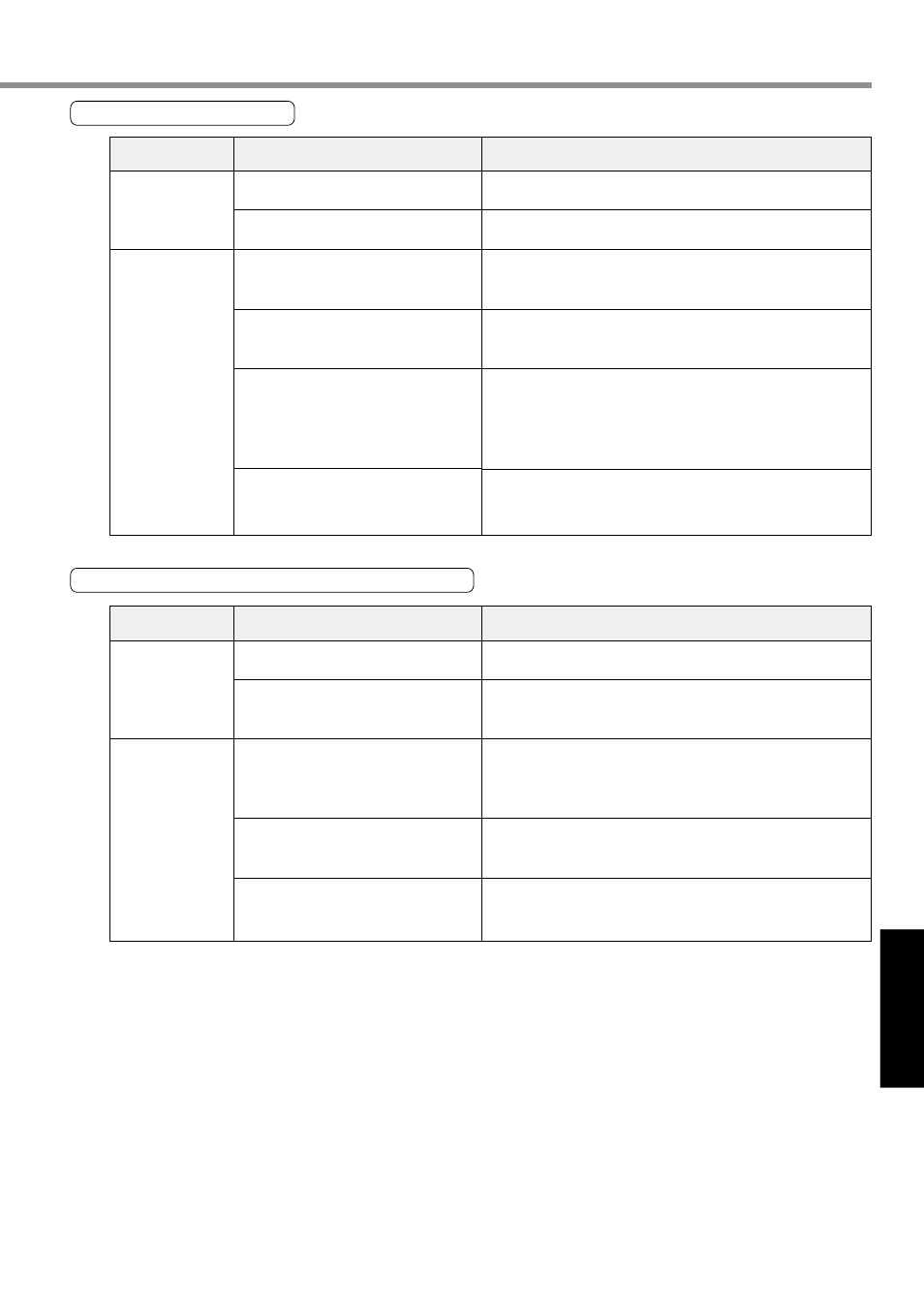

[Trouble Case]

T

rouble Case

Original position varies

Category

System

Wiring

Cause

Phase Z is not detected when the

original position is calculated.

Speed to creep to the original position

is fast.

Output of the original point proximity

sensor (nearest point dog sensor) is

chattering.

Noise is superposed on the encoder

wire.

Phase Z signal is not output.

Wiring of phase Z output is incorrect.

Action

Check if phase Z is superposed on proximity input (nearest

point dog sensor). Initialize correctly according to the controller.

Decelerate the initialization speed in the vicinity of the original

position, or extend the initialization sensor.

Using an oscilloscope, check input signal of the nearest point

dog sensor of the controller. Review wiring around the nearest

point dog and take action to reduce and prevent noise.

Take various actions: Reduce noise (by installing a noise filter/

inserting ferrite cores), shield I/F cable, use twist pair cable,

separate signal line from power line, etc.

Using an oscilloscope, monitor phase Z signal to be entered

into the controller. Check that the connector CN X5 pin 14 is

connected to the ground of the controller. For non-isolated

open collector interface, connect the ground of the driver.

Replace the driver and controller. Ask for repair.

Check that the line driver is connected at both sides. If the

controller does not have a differential input, use CZ output

(open collector).

The motor has abnormal sound or vibration

Category

Adjustment

Installation

Cause

The gains are set high.

A speed detection filter has changed.

Resonance between the equipment

(machine) and the motor is generated.

Motor bearing

Electromagnetic sound, gear sound,

braking sound, hub sound, rubbing

sound from the encoder etc.

Action

Decrease the values of the position loop gain Pr10 and velocity

loop gain Pr11 to lower the gains.

Increase the value of the speed detection filter Pr13 until the sound

reaches the allowable level, or reset it to a default setup of 4.

Readjust Pr14 (torque filter). Using the frequency characteristic

analysis program of the PANATERM

®

, check whether there is

any mechanical resonance. If so, set the notch frequency

Pr1D.

Drive the motor with no load to see if there is any sound or

vibration around the bearing. Replace the motor and check.

Ask for repair.

Drive the motor with no load and check. Replace the motor and

check. Ask for repair.