Gain adjustment, Adaptive filter, Cautions – Panasonic MINAS E-series User Manual

Page 131: Parameters to be set automatically

131

[Gain Adjustment]

Gain Adjustment

Adaptive Filter

Filters are effective when Pr02=2 (high-grade position control mode) and Pr21 is 1 to 3 or 7.

The adaptive filter reduces the resonance point vibration, by estimating resonance frequency from the vibration

component that appears at the motor operation, and removes the resonance component by torque command

through automatic setting of a coefficient of a notch filter.

The adaptive filter may not function normally under the following conditions. In such cases, use the anti-resonance

measures of 1st notch filter (Pr1D, 1E) according to the manual tuning procedure.

For details of the notch filter, refer to “To Reduce Mechanical Resonance” in Page 140.

Cautions

(1) After startup, immediately following the first Servo-ON or when you increase Pr22 (auto tuning), you may have

abnormal noise or oscillation before you identify load inertia or an adaptive filter is stabilized. However, this

doesn’t constitute abnormality if it disappears in no time. If oscillation or noise persists over 3 reciprocating

operations, you should take any of the following measures in any possible order:

1) Write into EEPROM parameters used during normal operation.

2) Decrease Pr22 (auto tuning).

3) Once set Pr21 (real time auto tuning mode setting) to 0 and disable an adaptive filter. Then, enable real time

auto tuning again (To disable inertia estimation/resetting of adaptive operation, or real time auto tuning, refer

to “Cancellation of the Automatic Gain Tuning” on Page 135).

4) Manually set a notch filter (Refer to “To Reduce Mechanical Resonance” on Page 140).

(2) In some cases, after abnormal noise or oscillation is generated, Pr20 (inertia ratio) or Pr2F (adaptive filter

frequency) may change to an extreme value. In such cases, you should take the measures described above.

(3) Among results of real time auto gain tuning, Pr20 (inertia ratio) and Pr2F (adaptive filter frequency) are written

into EEPROM every 30 minutes. When you power up again, auto tuning will be carried out using the data as an

initial value.

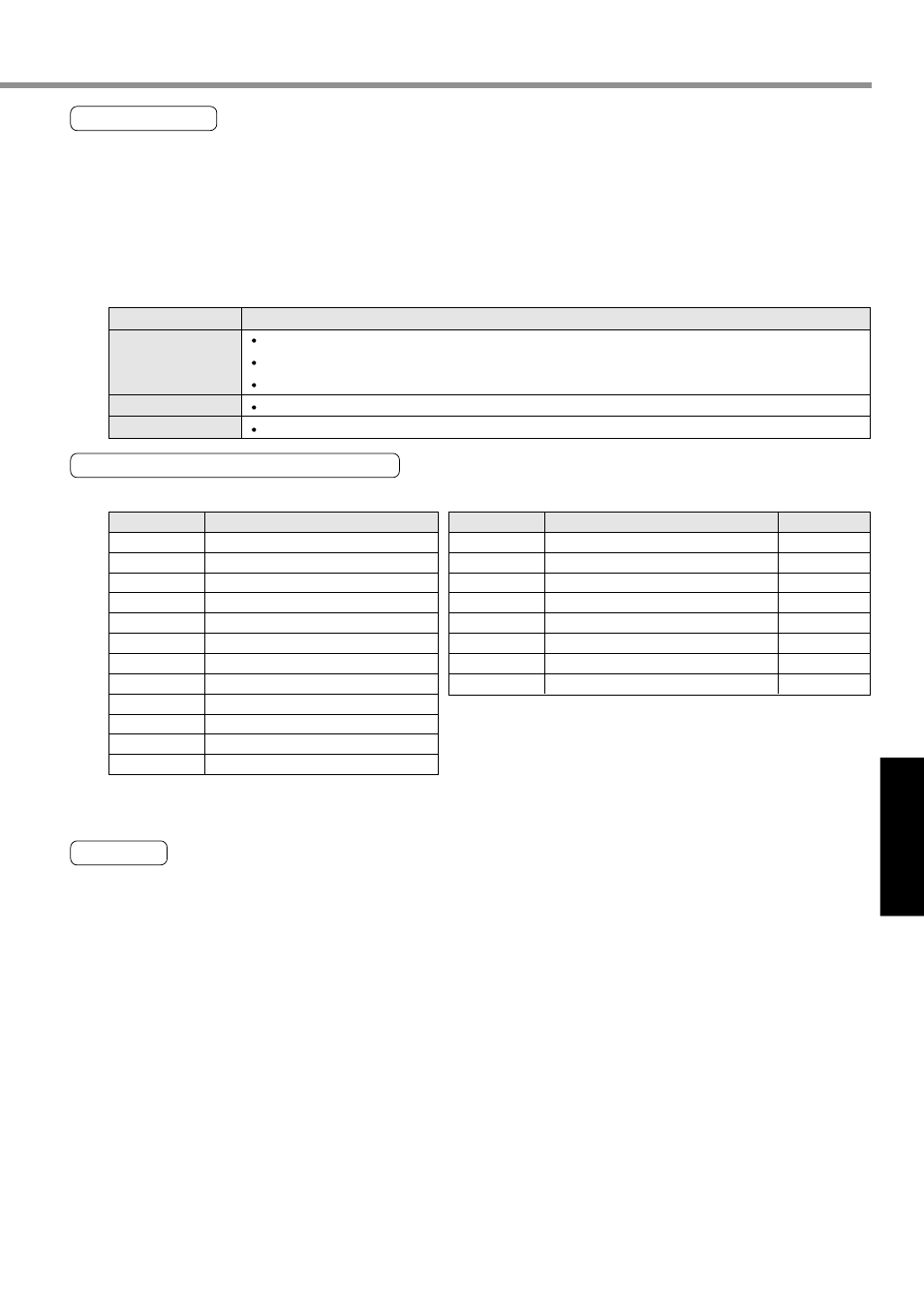

PrNo.

10

11

12

13

14

18

19

1A

1B

1C

20

2F

Name

1st position loop gain

1st velocity loop gain

1st velocity loop integration time constant

1st speed detection filter

1st torque filter time constant

2nd position loop gain

2nd velocity loop gain

2nd velocity loop integration time constant

2nd speed detection filter

2nd torque filter time constant

Inertia ratio

Adaptive filter frequency

PrNo.

15

16

30

31

32

33

34

35

300

50

1

10

30

50

33

20

Name

Setting

Velocity feed forward

Feed forward filter time constant

2nd gain action set-up

Position control switching mode

Position control switching delay time

Position control switching level

Position control switching hysteresis

Position loop gain switching time

Parameters to be Set Automatically

The following parameters are tuned automatically. The following parameters are also set up to the following fixed values automatically.

Resonance Point

Command Pattern

Load

Conditions that Hinder an Adaptive Filter from Functioning

When the resonance frequency is 300 [Hz] or lower.

When resonance peak or control gain is low, which does not affect the motor speed

When there is more than one resonance point

When the motor speed having high frequency component fluctuates due to nonlinear element such as backlash, etc.

When acceleration or deceleration is exponential such as 30000 [r/min] or more in 1 [s]

When real time auto tuning is in effect, you are not allowed to change any parameter to be automatically tuned.