Troubleshooting, Positioning accuracy is poor – Panasonic MINAS E-series User Manual

Page 152

152

Troubleshooting

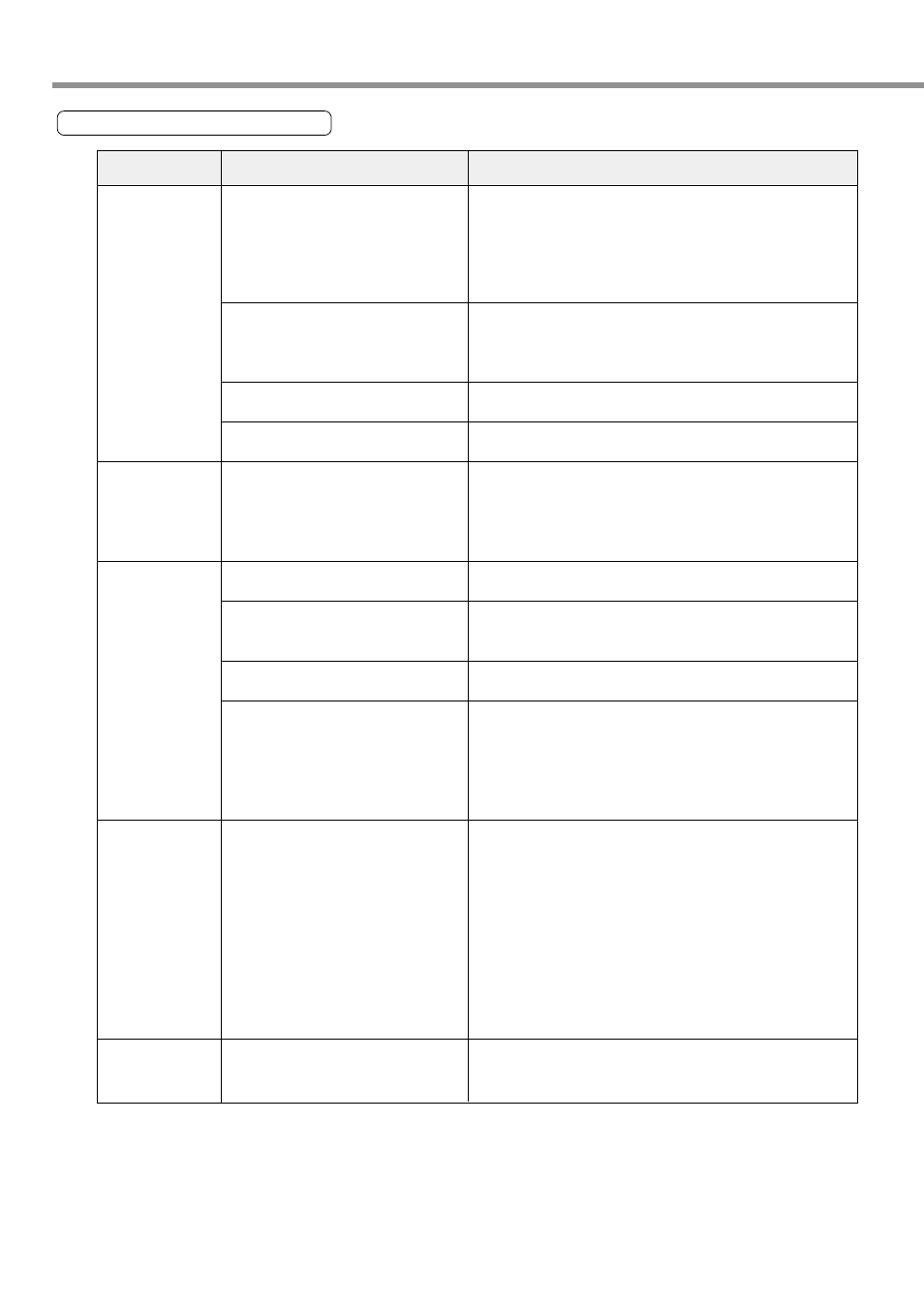

Positioning Accuracy is poor

Category

System

Adjustment

Parameter

Wiring

Installation

Cause

The position commands (amount of

command pulse) are not correct.

Reading of the positioning completion

signal occurs at the edge.

The shape and width of the command

pulses do not meet the requirements.

The deviation counter clear input CL

(CN X5 pin 4) is superposed with noise.

The position loop gain is small.

The setting of positioning completion

range is too high.

The command pulse frequency exceeds

500 kpps.

The incorrect dividing/multiplier ratio is

set.

The velocity loop gain is in proportional

control action under suspension.

The following signal inputs of the

connector CN X5 are chattering.

(1) Servo-ON signals

(2) Deviation counter clear input signals

Load inertia is high.

Action

Count the number of feedback pulses either by repeatedly

reciprocating for a fixed distance and using the monitoring

function of PANATERM

®

, or by using the monitor mode of

feedback pulse of the console. If the count does not return to

the same value, adjust the controller. Take action to reduce

noise on the command pulse.

By using the waveform graphic function of PANATERM

®

,

monitor a deviation when positioning completion signal is

generated. Read the signal from the controller at a midpoint of

the time span, and not at the edge.

If the command pulses are deformed or narrowed, adjust the

pulse generating circuit. Review the action against noise.

Not only take action against noise from external DC power

supply, but also do not wire any unused signal line.

Check amount of position deviation either by using the

monitoring function of PANATERM

®

or in the monitor mode of

the console.

Increase the value of Pr10 so as not to cause oscillation, and

check it.

Decrease the value of the In-position range Pr60 so that the

completion signal will not cause chattering.

Lower the command pulse frequency. Change the dividing/

multiplier ratio of the numerator of 1st/2nd command pulse ratio

Pr46 to Pr47.

Check whether repeatability is the same.

•

Set the velocity loop integration time constant Pr12 and

Pr1A below 999.

•

Modify wiring and connection so that the second gain action

set-up Pr30 is 1, and connection between the gain switching

input connector CN X5 pins 5 and 13 is turned OFF. Check

the controller.

(1) Using the I/O status display function, check wiring and

connection between the connector CN X5 pins 2 and 13.

Modify the wiring and connection so that Servo-ON signal

successfully turns ON. Check the controller.

(2) Using the I/O status display function, check wiring and

connection between the connector CN X5 pins 4 and 13.

Modify the wiring and connection so that the deviation

counter clear input successfully turns ON. Check the

controller.

Check overshot in halt condition, by using the waveform graphic

function of PANATERM

®

. Even when it is not corrected after

adjusting gains, increase capacity of the motor and driver.