Trouble case – Panasonic MINAS E-series User Manual

Page 147

147

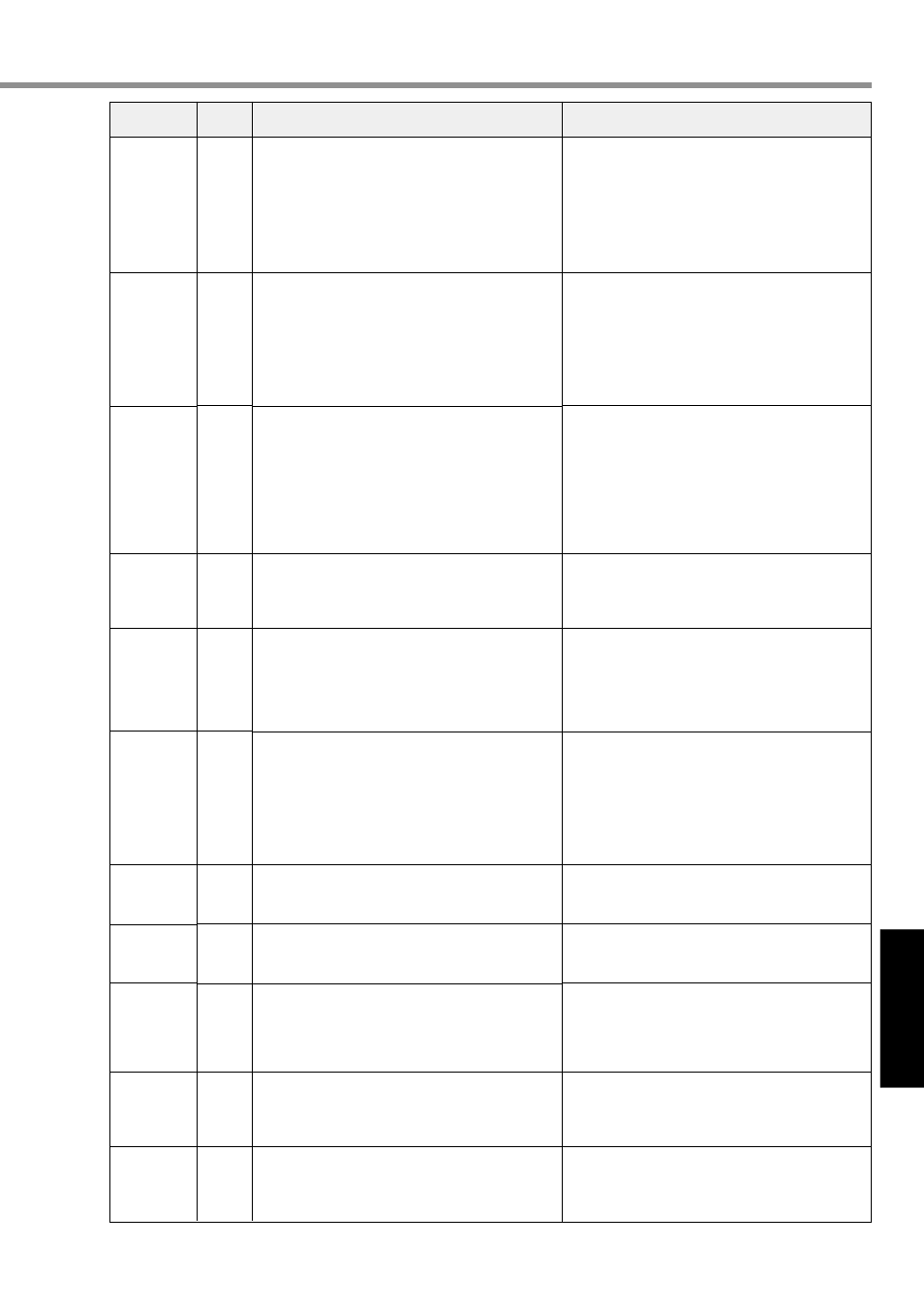

[Trouble Case]

T

rouble Case

Protective

Functions

*Encoder

communi-

cation data

error

protection

Position

over-

deviation

protection

Over-

velocity

protection

(OS)

Command

pulse

multiplier

error

protection

Deviation

counter

overflow

protection

Software

limit

protection

*EEPROM

parameter

error

protection

*EEPROM

check code

error

protection

Overtravel

inhibit input

protection

*ABS 1-

rotation

counter

error

protection

*ABS multi-

rotation

counter

error

protection

Alarm

code No.

23

24

26

27

29

34

36

37

38

44

45

Cause

Data from the encoder results in communication

error, which is mainly caused by noise. Although

the encoder cable is connected correctly, data

results in communication error.

careful as the motor automatic recognition

abnormality protection (alarm code No.95) will be

activated when you power on again.

The position deviation pulse exceeds the position

over-deviation set-up, Pr63.

(1) The motor operation does not respond to a

command.

(2) The position over-deviation set-up Pr63 is low.

(1) The rotation speed of the motor exceeds a

specified value.

(2) Torque limit switching input selection Pr06 is

set to 2, and 1st and 2nd over-speed level set-

up Pr70, Pr73 are set to 0.

The dividing/multiplier ratio set with the numerator

of 1st and 2nd command ratio Pr46 and Pr47 is

not appropriate.

A value of the deviation counter exceeds 2

27

(134217728).

The motor operation exceeds the motor

operational range set in Pr26 (Software limit

setting) for the position command range.

(1) The gain is not appropriate.

(2) The value set in Pr26 is too small.

Data in the parameter storage area is corrupt

when it is read from EEPROM upon power-on.

EEPROM write check data is corrupt when it is

read from EEPROM upon power-on.

Both CW and CCW overtravel inhibit input turn off.

The encoder detected abnormality of a single-turn

counter.

The encoder is defective.

The encoder detected abnormality of a multi-turn

counter.

The encoder is defective.

Action

Ensure that the supply voltage of the encoder is

DC5V

±5% (4.75 to 5.25V). Be careful, in

particular, when the encoder cable is long. If it is

bundled with the motor wire, separate them.

Connect the shield to FG --- See the encoder

wiring diagram.

(1) Check that the motor rotates in accordance

with the position command pulse. Using the

torque monitor, ensure that output torque is

not saturated. Adjust gains. Maximize torque

limit set-up Pr5E. Correct encoder wires as

per the wiring diagram. Extend acceleration/

deceleration time. Alleviate load and slow

down speed.

(2) Increase Pr63.

(1) Decrease the speed to prevent over-speed

command from being issued. Set dividing/

multiplier ratio so that input frequency of a

command pulse is 500 kpps or less. In the

event of overshoot due to poorly adjusted

gains, readjust them. Connect encoder wires

as per wiring diagram.

(2) If you select torque limit switching input, set

Pr70 and Pr73 to a value within the use range

speed of the motor.

Using Pr46 and Pr47, reduce the multiplier ratio.

Set the dividing/multiplier ratio so that the

command pulse frequency will not exceed the

maximum input pulse of 500 kpps or less.

Check that the motor rotates in accordance with

the position command pulse. Using the torque

monitor, ensure that output torque is not

saturated. Adjust gains. Maximize torque limit

set-up Pr5E. Correct encoder wires as per the

wiring diagram. Extend acceleration/deceleration

time. Alleviate load.

(1) Check the gain (the balance between the

position loop gain and the speed loop gain)

and the inertia ratio.

(2) Increase the set value in Pr26.

Set Pr26 to “0” in order to disable the

protection function.

Reset all the parameters.

If the error persists, the driver may have failed.

Replace it. Then, return it to the sales agent for

inspection (repair).

The driver may have failed. Replace it. Then,

return it to the sales agent for inspection (repair).

Check if limit switches, electric wires, and power

supply for CW/CCW overtravel inhibit input are

normal. Especially, check whether the power

supply for control signal (DC12 to 24V) rises

without delay. Check setting of Pr04 and correct

wiring.

The motor may have failed. Replace it. Then,

return it to the sales agent for inspection (repair).

The motor may have failed. Replace it. Then,

return it to the sales agent for inspection (repair).