Software limit function, Troubleshooting – Panasonic MINAS E-series User Manual

Page 148

148

Troubleshooting

Protective

Functions

*Encoder Z-

phase error

protection

*Encoder

CS signal

error

protection

*Motor auto

recognition

error

protection

*LSI setup

error

protection

*Other

trouble and

error

Alarm

code No.

48

49

95

96

Nos.

other

than the

above

Cause

Missing phase Z pulse of 2500 [P/r] 5-serial

encoder is detected.

The encoder is defective.

The abnormal logic of CS signal of 2500 [P/r] 5-

serial encoder is detected.

The encoder is defective.

(1) The motor is not compatible with the servo

driver.

(2) The encoder is not connected at power-on.

Before power-on, if (1) the encoder wire is

disconnected, or (2) data from the encoder results

in communication error, be careful as the motor

automatic recognition abnormality protection

(alarm code No.95) will be activated when you

power on again.

In case of (1) and (2) above, take action for alarm

codes No.21 and No.23.

Setting of LSI does not complete successfully due

to excessive noise.

The self-diagnostic function of the driver is

activated and some abnormality occurs in the

driver.

The control circuits malfunction due to excessive

noise.

Action

The motor may have failed. Replace it. Then,

return it to the sales agent for inspection (repair).

The motor may have failed. Replace it. Then,

return it to the sales agent for inspection (repair).

1) Change the motor to a new motor compatible

with the servo driver.

2) Check connection of the encoder.

Take countermeasure against noise.

Power off and on again. If the display still

appears and the error is repeated, the motor and

driver may have failed. Shut down the power and

replace them. Then, return them to the sales

agent for inspection (repair).

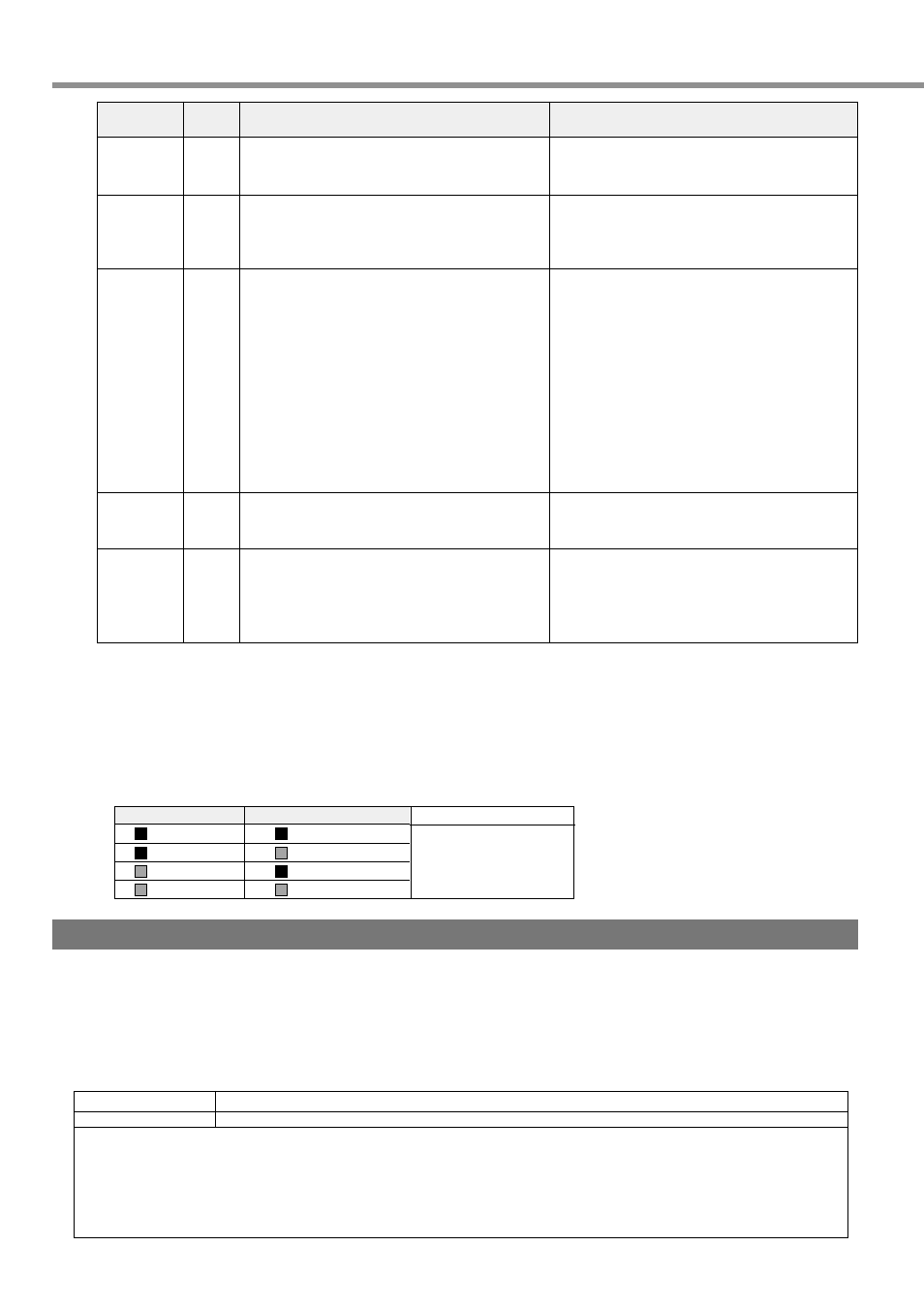

Alarm Code LED

Red

Orange

Red

Orange

Alarm content

Other trouble/error

STATUS LED

Red

Red

Orange

Orange

Load factor and regenerative resistor load factor can be checked in the monitor mode of PANATERM

®

or console.

•

Power voltage shortage protection (Alarm Code No. 11), EEPROM parameter error protection (Alarm code

No. 36), EEPROM check code error protection (Alarm code No. 37), Overtravel inhibit input protection

(Alarm code No. 38), Motor auto recognition error protection (Alarm code No.95) and LSI setup error

protection (Alarm code No.96) are not memorized in “Alarm History”.

•

If other trouble/error occurs, STATUS LED and Alarm LED (ALM Code) could eventually turn ON simulta-

neously in 4 different modes given below, instead of blinking (flashing) as staged in the above Table.

Software limit function

(1) Outline

If the motor operation exceeds the motor operational range set in Pr26 (Software limit protection) for the position

command range, then the alarm can be stopped with the software limit protection (error code No. 34).

Using this function prevents the load from colliding with the edges of the machine due to the oscillation of the motor.

(2) Scope

This function can operate under the following conditions:

Control mode

Conditions under which the software limit functions

Position control mode Pr02 = 0: High-speed response position control Pr02 = 2: Highly-functional position control

(1) Servo must be turned ON.

(2) Pr26 (Software limit setting) must be set to a value other than “0”.

(3) The motor’s operational range must be within 2147483647 for both CCW and CW since the position command parameter range

was reset to “0”.

Once the condition in (3) has been breached, then the software limit protection will be disabled until the condition for which the (5)

Position command parameter range is cleared is met.

If condition (1) or (2) is not met, then the position command parameter range will be cleared to “0”.