Principle of operation – Delta MMC120 User Manual

Page 9

9

Principle of Operation

Position Measurement

Each Motion Control Module has interface circuitry for multiple magnetostrictive

transducers. Each axis can be configured for a Start/Stop transducer or a Pulse Width

Modulated transducer by changing the axis’s Configuration Word. To make a

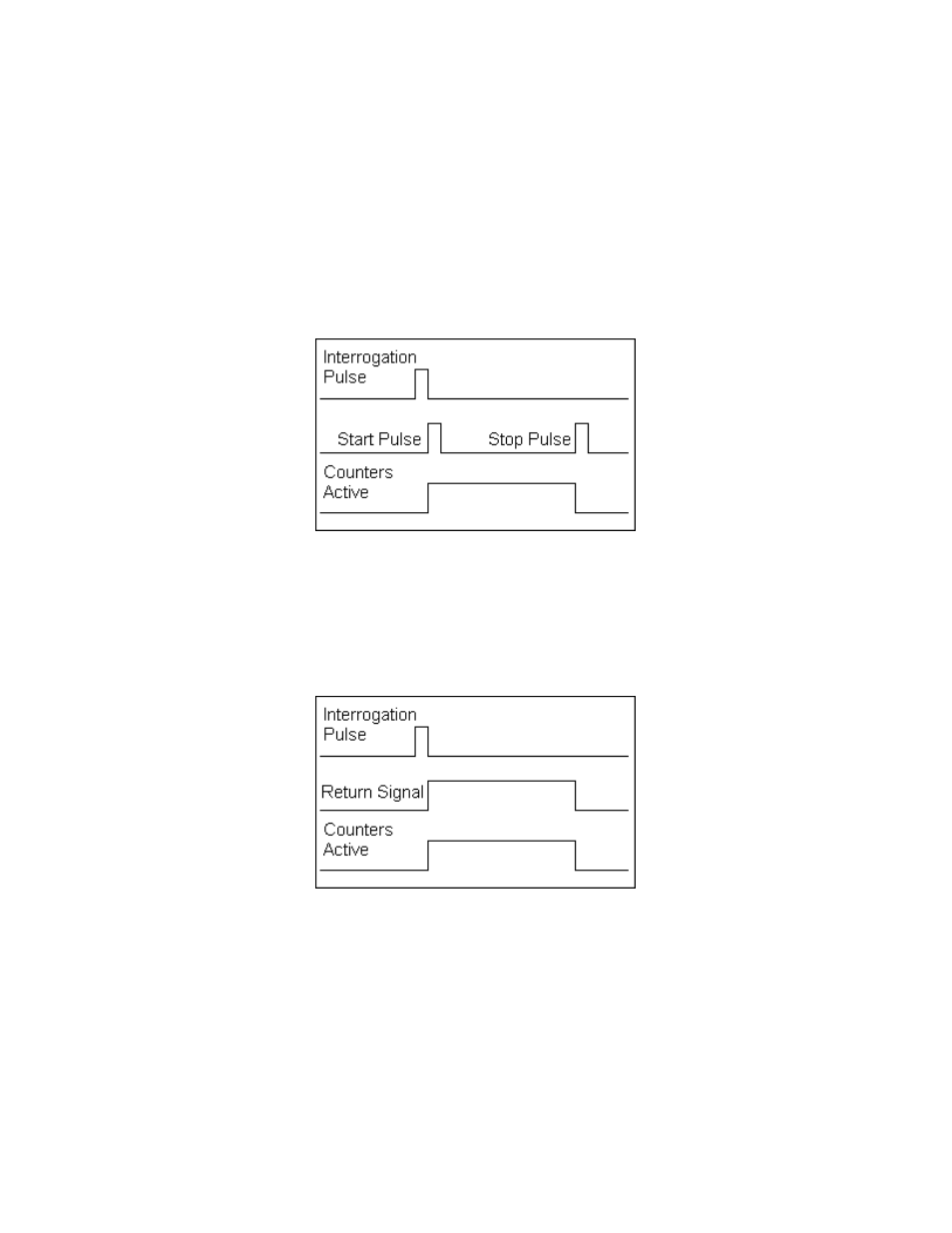

measurement with a Start/Stop transducer, the Motion Controller sends an interrogation

pulse to the transducer. The transducer responds by returning 2 pulses -- a Start pulse

and a Stop pulse. The counters on the Motion Controller are active between the two

pulses. The time between the pulses is proportional to the transducer position.

Start/Stop Pulse Transducer

To make a measurement with a Pulse Width Modulated transducer, the Motion Controller

sends an interrogation pulse to the transducer. The transducer responds with a return

signal that is high while the transducer is determining its position. The counters on the

Motion Controller are active while the return signal is high. The width of the return

signal is proportional to the transducer position.

Pulse Width Modulated Transducer

The Motion Controller converts the Transducer Counts read from the counters to an

ACTUAL POSITION

in user-defined Position Units (usually 0.001 inch) for use by the

Programmable Controller.

Control Loop

This motion controller is a targeting controller; each millisecond the onboard

microprocessor updates the

TARGET POSITION

and

TARGET SPEED

values. For