Delta MMC120 User Manual

Page 10

10

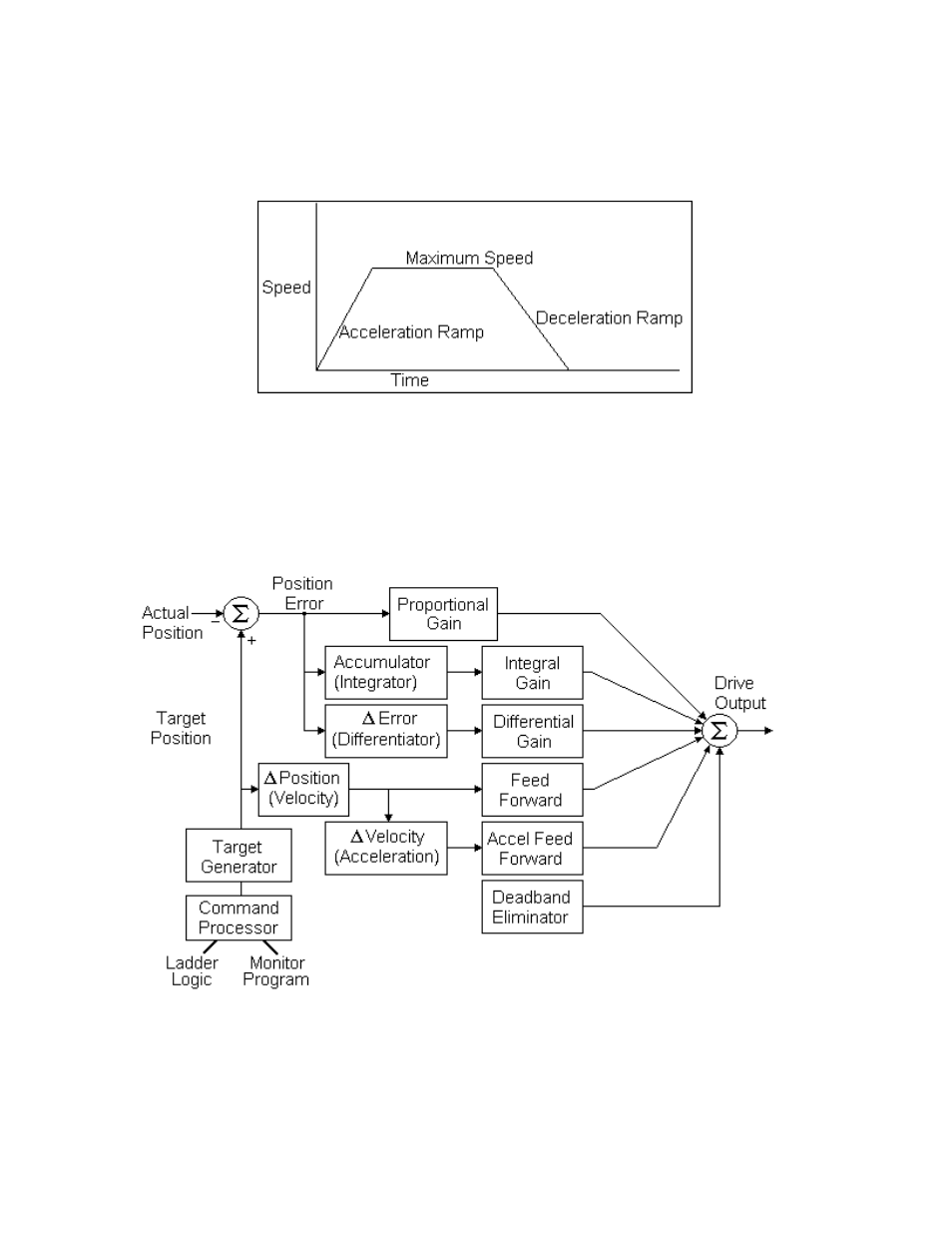

point-to-point moves,

TARGET POSITIONS

are generated so the target speed follows a

profile. The

MODE

,

ACCELERATION

,

DECELERATION

,

SPEED

, and

COMMAND

VALUE

(requested position) are used to generate the profile. They are specified by the

user, and can be changed while the axis is moving. A trapezoidal profile is shown here.

The

ACTUAL POSITION

measured by the magnetostrictive transducer is compared with

the

TARGET POSITION

to determine the position error. Every millisecond the position

error is used to calculate the closed loop components of the drive output. It is multiplied

by the

PROPORTIONAL GAIN

to calculate the proportional component of the drive

output. The accumulated position error is used, along with the

INTEGRAL GAIN

, to

calculate the integral portion of the drive output. The change in position error, along

with the

DIFFERENTIAL GAIN

, is used to calculate the differential portion of the drive

output.

In addition to the closed loop drive, this motion controller has two feed forward terms,

made up of

EXTEND

and

RETRACT FEED FORWARD

, and

EXTEND

and

RETRACT

ACCELERATION FEED FORWARD

. These feed forward terms give approximately

the drive needed to make the axis follow the target, freeing the PID loop to correct for

non-linearity in the system and changes in system load.