Section 10 testing and troubleshooting, 1 troubleshooting, 2 common problems – SilentKnight 5700 User Manual

Page 158: Testing and troubleshooting, 1 troubleshooting -1 10.2 common problems -1

151295

10-1

Section 10

Testing and Troubleshooting

10.1 Troubleshooting

This section of the manual offers suggestions for troubleshooting hardware problems. Please read this section if

you encounter a problem when installing the control panel. If these suggestions do not solve your problem or if

you encounter a problem that is not listed here, contact Silent Knight Technical Support for assistance.

10.2 Common Problems

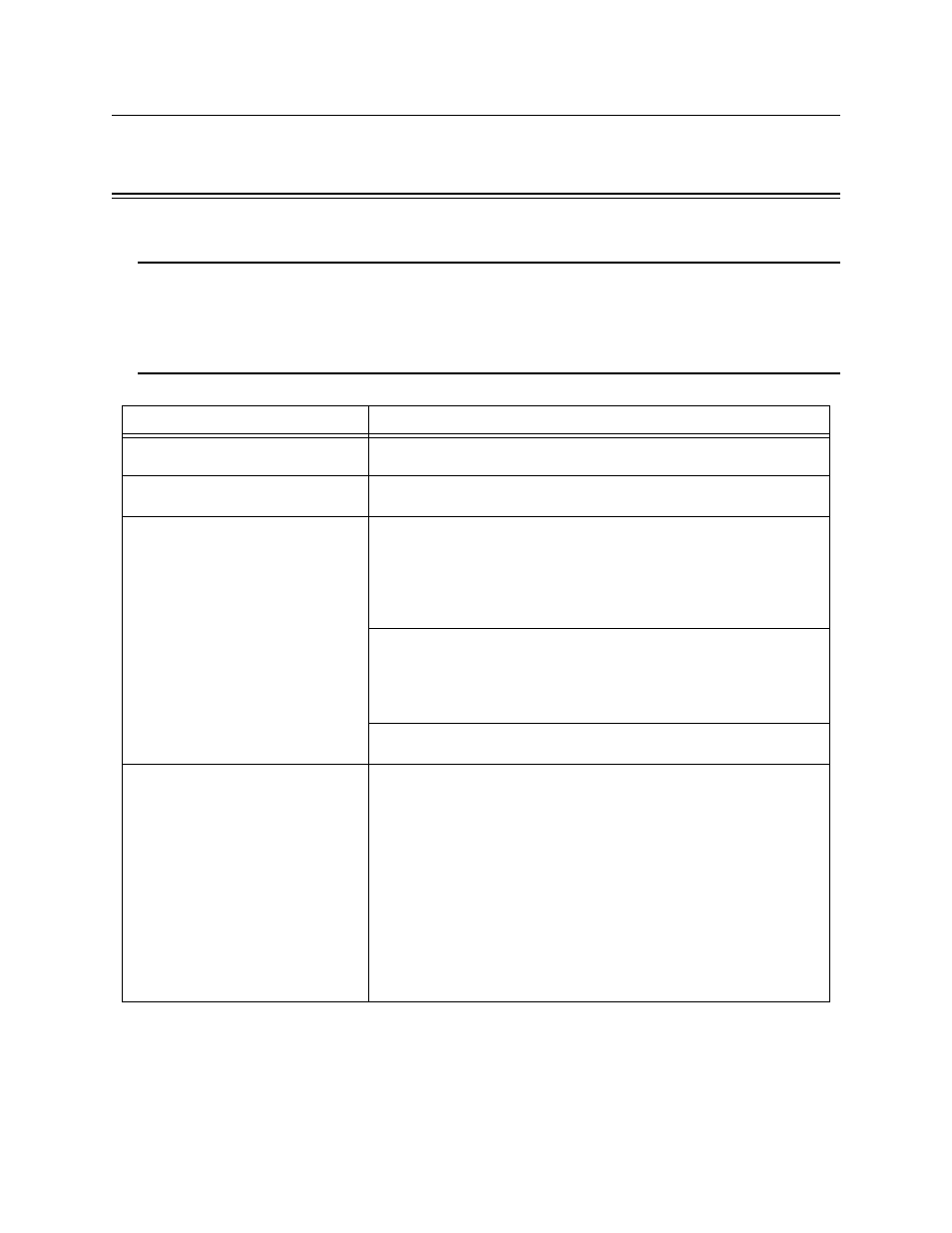

Problem

Possible Cause / Suggested Actions

Trouble message “DBL ADDR” (Double

Address) displays on LCD.

An address has been assigned to more than one detector. Correct the address

following the procedure described in Section 5.

Auxiliary power or notification circuits

have incorrect polarity.

Correct polarity. For notification and auxiliary power circuits: When in alarm or

powered, terminals labeled “X” are positive, terminals labeled “O” are negative.

SLC devices are not being recognized

(trouble message “Missing” displays).

Check hardware connections.

If devices are physically connected, make sure wiring is correct (see Section

5.4). For the main panel, the positive side of device must be connected to

terminal 34; the negative side must be connected to Terminal 33. For SLC

devices, make sure the device connects to the SLC loop via the SLC OUT

terminals.

Make sure SLC devices have been addressed properly following the procedure

described in Section 5.

For contact monitor modules, which are addressed using DIP switches, the DIP

switch must be set to the correct address before power is applied to the SLC loop.

If this procedure is not followed, the device will have an incorrect address.

Make sure correct polarity has been observed for SLC device wiring. See Section

5.

SLC devices are not being recognized

(trouble message “Missing” displays on

the annunciator).

Check that SLC loop impedance is within the required range.

To measure impedance, use the following procedure.

1. Disconnect both wires from the terminal block at the panel (SLC devices can

remain connected).

2. Measure the impedance from positive to negative and from negative to posi-

tive. Both measurements should be greater than 500 K ohms. If the installa-

tion uses T-taps, test each T-tap individually.

3. Temporarily connect the positive wire to the negative wire of the SLC loop at

the point farthest from the panel (SLC devices can remain connected).

4. Measure the impedance from positive to negative and from negative to posi-

tive. Both measurements must be less than 50 ohms.