Recommended cable – Rockwell Automation 20D PowerFlex 700H and 700S Frame 9...14 Drives User Manual

Page 192

192

Rockwell Automation Publication PFLEX-IN006E-EN-P - July 2013

Appendix C

PowerFlex 700S Resolver Feedback Option Card

Wiring the Resolver

Feedback Option Card to a

Resolver

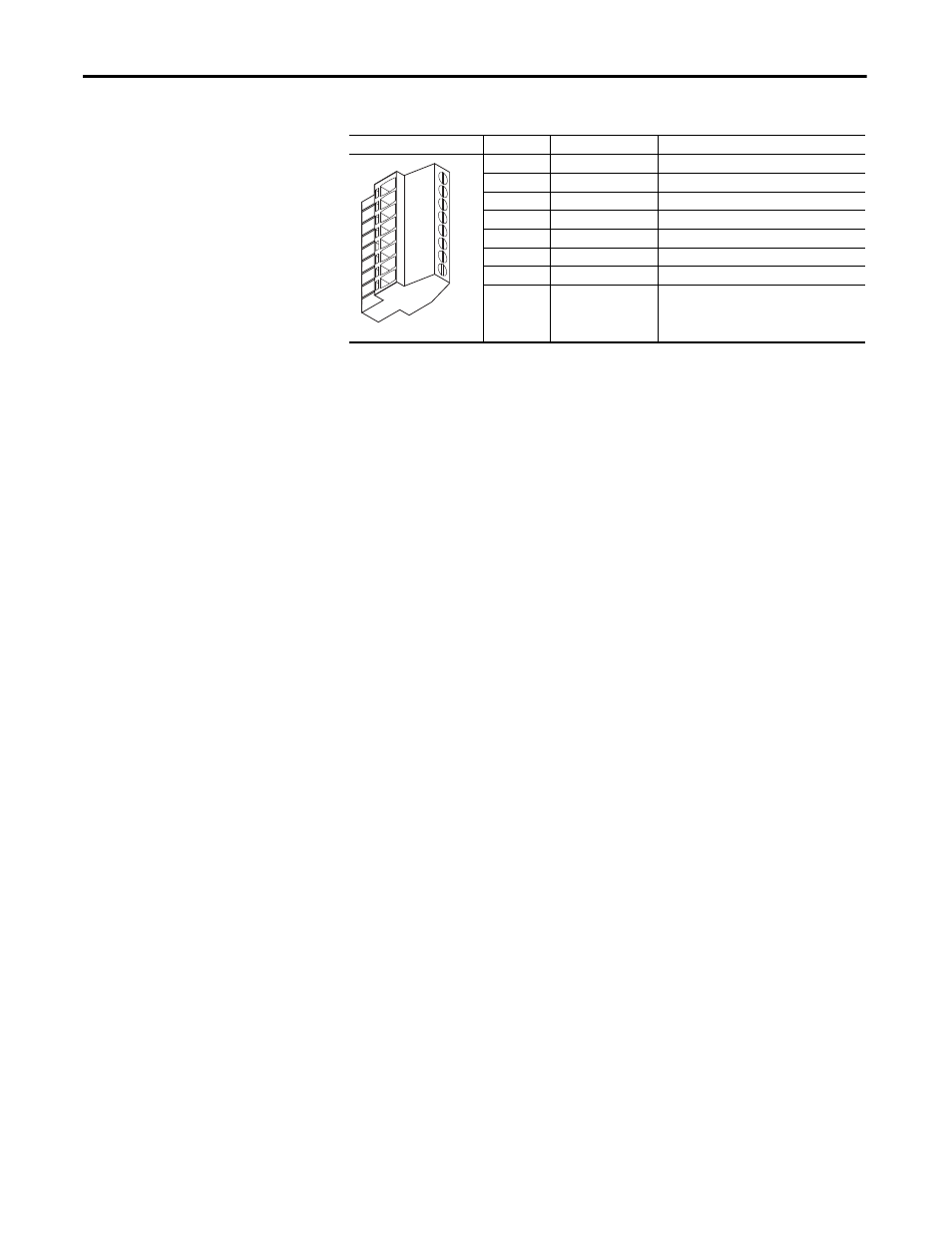

Table 21 - Terminal Block Description

Recommended Cable

Rockwell Automation strongly recommends the use of Reliance Electric 417900-

207CG or Belden 9730 cable for installation, or an equivalent cable that meets

these specifications:

•

3 Twisted Pairs, 80 °C, 300V

•

Chrome FPR Jacket, Plenum Rated

•

Conductor Size: 18 AWG

•

Twists Per Inch: 2-3 twists per inch of wire lay per pair

•

Capacitance Per Pair: not to exceed 30 pF per foot ± 0.3 pF as read on a

GEN_RAD Model 1658 RLC Digibridge or equivalent

•

Capacitance Difference Pair to Pair: not to exceed 0.6 pF per foot as read

on a GEN_RAD Model 1658 RLC Digibridge or equivalent

•

Resistance per 1000 ft: 17.15

Ω

±10%

•

Inductance per 1000 ft: 0.13 mH ±10% as read on a GEN_RAD Model

1658 RLC Digibridge or equivalent

•

Insulation Thickness: 0.008 in.

•

Conductor Stranding 16/30

•

Jacket Thickness: 0.018 in.

Terminal

Signal

Description

8

REF HIGH

Positive Reference signal

7

SHIELD

Connection point for resolver cable shield

6

REF LOW

Negative Reference signal

5

SIN HIGH

Positive Sine signal

4

SHIELD

Connection point for resolver cable shield

3

SIN LOW

Negative Sine signal

2

COS HIGH

Positive Cosine signal

1

COS LOW

Negative Cosine signal

12

34

5

6

7

8