Output power wiring – Rockwell Automation 20D PowerFlex 700H and 700S Frame 9...14 Drives User Manual

Page 116

116

Rockwell Automation Publication PFLEX-IN006E-EN-P - July 2013

Chapter 8

Frame 12 Mechanical Installation

Output Power Wiring

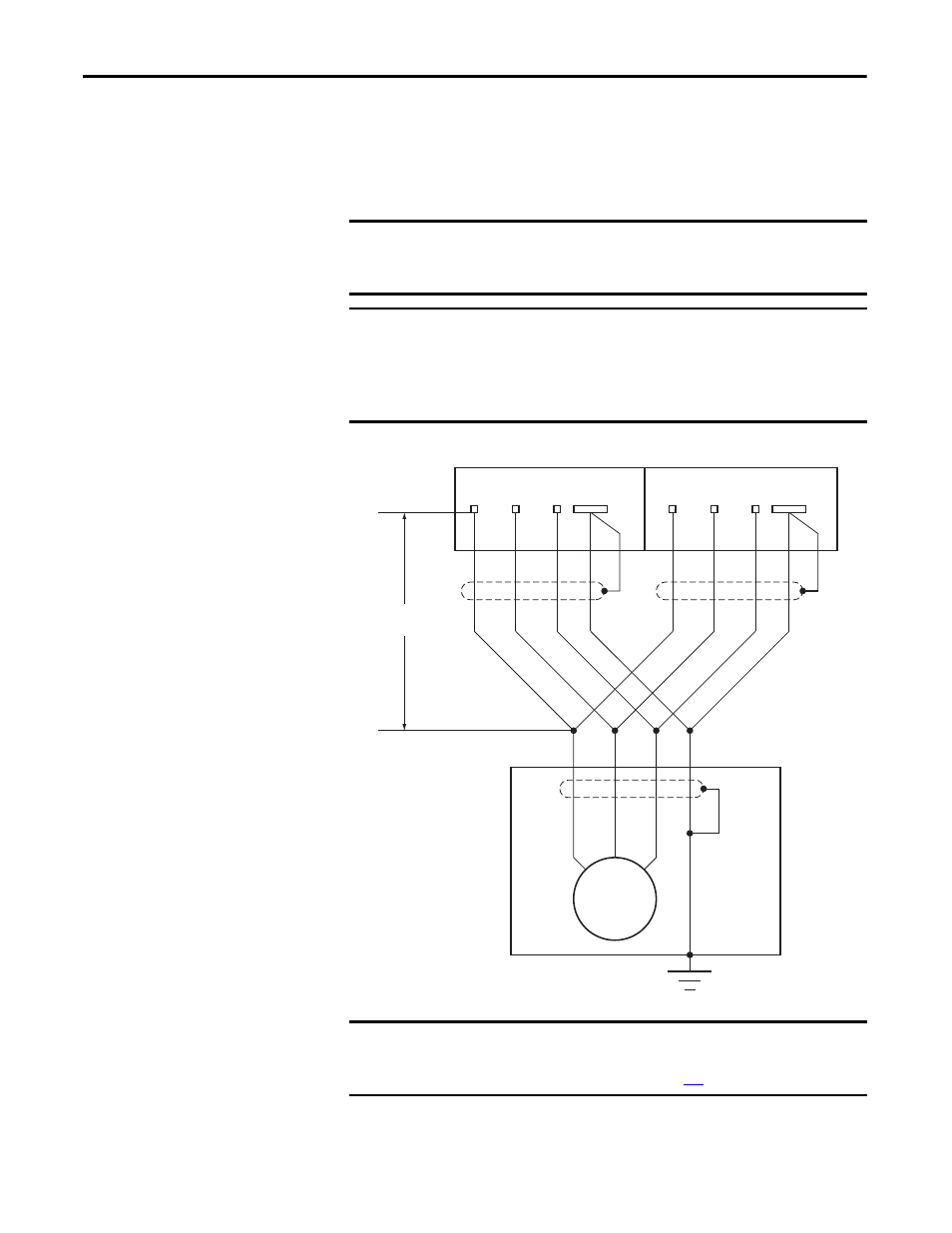

Frame 12 drives utilize two parallel power structures, and therefore have two sets

of output power terminals. You must connect the motor to both sets of output

power terminals.

Figure 46 - Frame 12 Motor Wiring Example

IMPORTANT

Parallel wiring must have the same cable dimensions, type and routing. Non-

symmetrical wiring may cause unequal loading between the converters and

reduce the drive’s ability to deliver current to the motor.

IMPORTANT

The minimum cable length for parallel motor cables from the drive to the point

where the cables connect is 5 m (16.4 ft). Join the parallel cables at the motor

end (not the drive end). Or, install a reactor on the output of each power

module with a minimum of 5 μH prior to joining the parallel cables at the

motor end.

IMPORTANT

Once power wiring has been completed, the protective covers must be

installed before energizing the drive. Installation is in reverse order of removal

(see Remove the Protective Covers on page

1T1

1T2

1T3

2T1

2T2

2T3

PE

PE

Motor Frame

Motor

5 m

minimum