Rockwell Automation FlexPak 3000 Power Module SW-Version 4.3 User Manual

Page 189

APPENDIX E

49’1340 e

FlexPak 3000

E-5

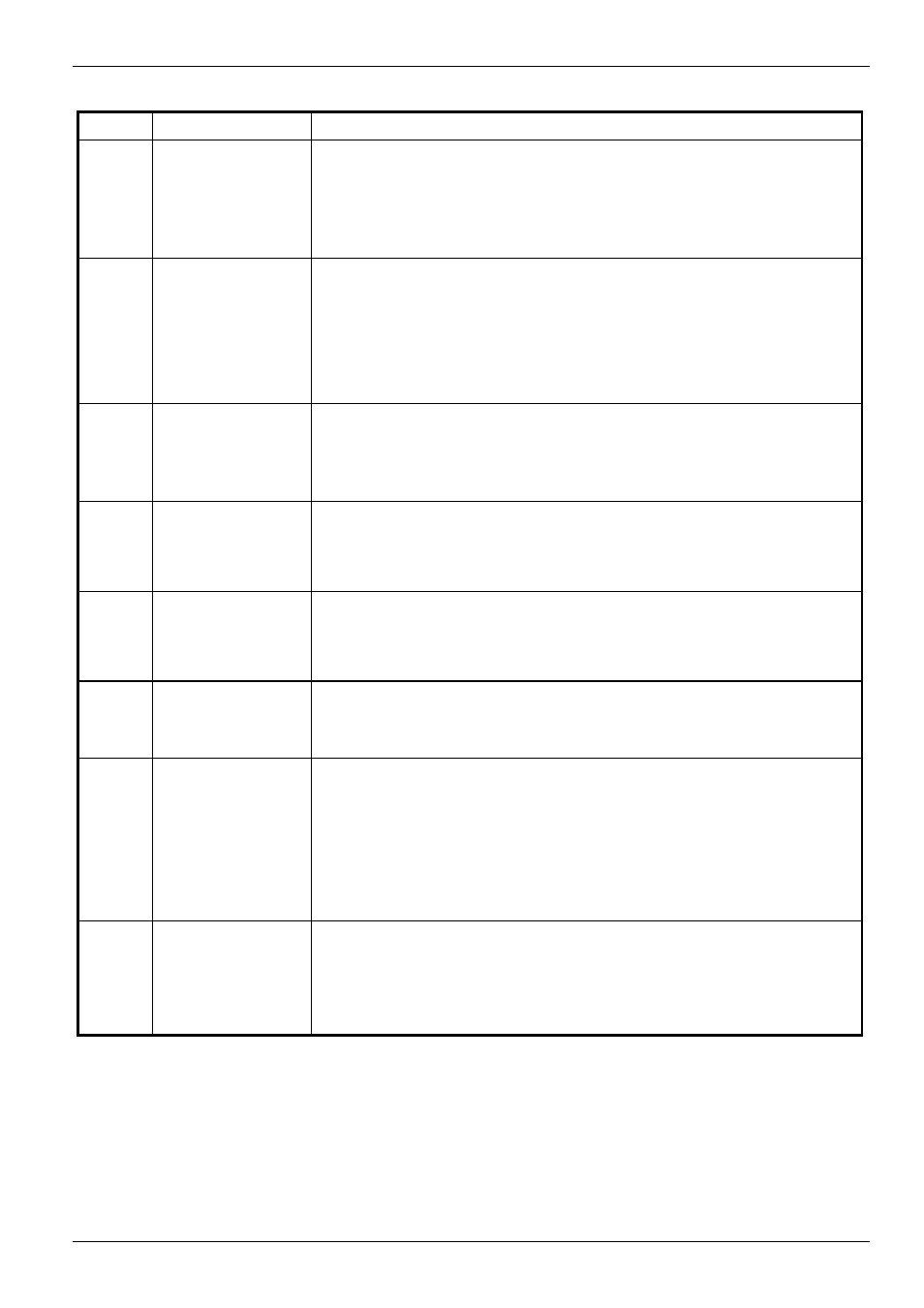

Table E.1 - Fault Codes (Continued)

CODE DISPLAY

DESCRIPTION

F00063

SELF TUNING

FAULT

Maximum current with minimum rotation.

Possible causes:

•

Motor can not rotate freely due to mechanical friction.

•

Motor load is too high.

•

Motor field not at normal operating temperature.

F00064

SELF TUNING

FAULT

Attached inertia is out of range.

Possible causes:

•

Maximum self tune speed reached.

•

Overhauling load present.

•

High mechanical friction present.

•

The Speed Loop can not be self tuned. Tune Speed Loop manually.

F00065

SELF TUNING

FAULT

Speed unstable.

Possible causes:

•

CML not properly tuned before Speed Loop.

•

Tachometer feedback connected incorrectly.

F00066

SELF TUNING

FAULT

SELF TUNE STABILITY

(P.219)

is too low.

Possible cause:

•

Specified stability is less than that calculated by CML self tuning, use

50 or greater.

F00067

SELF TUNING

FAULT

SELF TUNE STABILITY

(P.219)

is too low.

Possible cause:

•

Specified stability is less than that calculated by CML self tuning, use

75 or greater.

F00089

to

F00099

SELF TUNING

FAULT

Fatal self tuning fault occurred.

Possible cause:

•

Self tuning was unable to complete; tune manually.

F00100

1)

MAIN CONTACTOR

DID NOT OPEN

The main contactor was not open when a run or jog request is applied.

Possible causes:

•

Disconnected, loosely connected, or damaged main contactor (K1M)

or Aux. contactor (K1) wiring.

•

Main contactor or Aux. Main contactor failure.

•

Disconnected, loosely connected, or damaged main contactor

control wiring (MCR).

F00200

POWER FAILURE

The power supply input voltage momentarily went below tolerance.

Possible causes:

•

AC line voltage dip.

•

Disconnected, loosely connected, or damaged J7 ribbon cable or

power supply input wiring

1) When after stop command, the auxiliary contactor does not indicate that the main contactor opened,

this fault indication is 1000 msec time delayed.