4 drive description – Rockwell Automation FlexPak 3000 Power Module SW-Version 4.3 User Manual

Page 15

INTRODUCTION TO THE DRIVE

49’1340 e

FlexPak 3000

2-7

2.4 Drive

Description

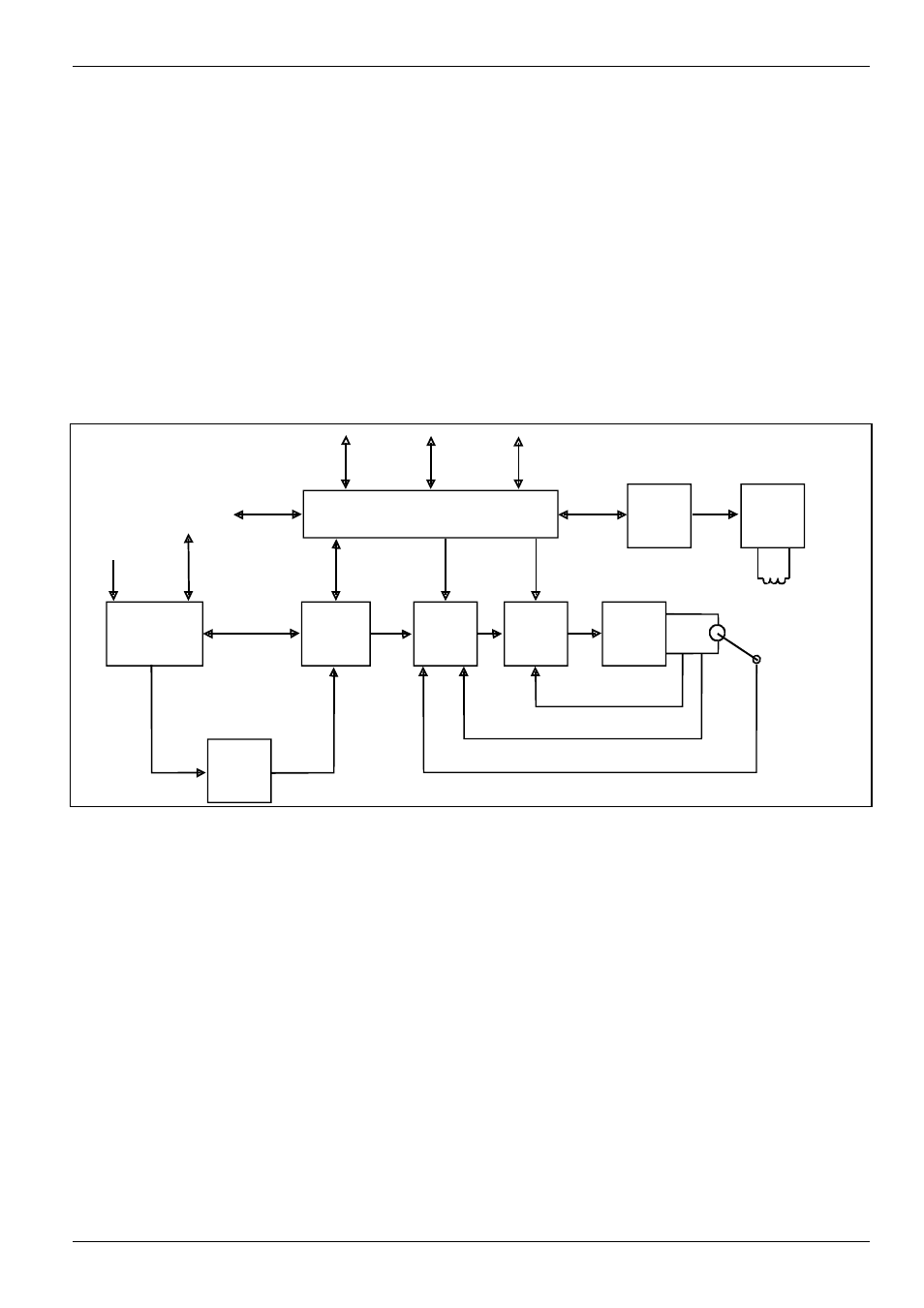

The drive is a full-wave power converter without back rectifier, complete with a digital current

minor loop and a digital major loop for armature voltage or speed regulation by tachometer

feedback. Figure 2-1 shows a block diagram of the Drive.

The Drive employs a wireless construction and uses a keypad for drive setup, including

parameter adjustments and unit selection, monitoring and diagnostics. Multiple language

capability in English, French, German, Spanish, Italian and ‘Code’ is available. Reference,

feedback, and metering signals can be interfaced to the drive. The drive can be controlled

locally by the Operator Interface Module (OIM) Keypad or remotely by using the terminals at the

regulator board terminal strip (see Section 3 for terminal connections). Based on the active

control source selected using the CONTROL SOURCE SELECT key, the OIM displays the

control source as "KEYPAD" or "TERMBLK" (regulator board terminal strip), or "NETWORK"

(if an optional network communication board is installed).

DRIVE CONTROL SIGNALS AND SEQUENCING

OIM

SERIAL

NETWORK

SPEED

LOOP

CURRENT

MINOR

LOOP

(CML)

FIELD

CONTROL

S6/S6R

POWER

UNIT

FIELD

POWER

SUPPLY

SPEED

REFERENCE

SELECTION

AND

SCALING

OUTER

CONTROL

LOOP

(OCL)

Regulator Board

Terminal Strip

I/O Expansion

Board

Current Feedback

Voltage Feedback

Tachometer Feedback

MOTOR ARMATURE

ANALOG OR PULSE

TACHOMETER

MOTOR FIELD

DIGITAL,

ANALOG, &

FREQUENCY

INPUTS/

OUTPUTS

Figure 2-1 - FlexPak 3000 Functional Block Diagram