Rockwell Automation FlexPak 3000 Power Module SW-Version 4.3 User Manual

Page 156

APPENDIX B

FlexPak 3000

49’1340

e

B-52

OIM Menu Path(s):

Drive Reference - Drive Reference Trim

The choices are:

•

REGISTER: The reference is TRIM REF REGISTER (P.107)

•

ANALOG MANUAL: The reference is the analog manual reference input from terminals 16, 17,

and 18 of the Regulator board. Do not select this option if this input is being used for the analog

manual speed reference.

•

ANALOG IN 1 or 2: The reference is from an I/O Expansion kit analog input. These are only

available if an I/O Expansion kit is installed.

•

NETW IN REG 1, 2, or 3: The reference is from a network input register. These options are

available only if a network kit is installed. Note that the network input registers are updated only

when CONTROL SOURCE SELECT (P.000) is set to network and the network is active.

TRIM REF REGISTER (P.107)

Drive register to manually set the trim reference value used by the drive.

Parameter Range:

+100.0%

Default Setting:

0%

Parameter Type:

Tuneable

OIM Menu Path(s):

Drive Reference - Drive Reference Trim

UNDERWIND ENABLE (Alternate network map, Drop_1, register 32, Bit 5)

Setting this bit to 1 enables two inverter blocks that permit underwind operation.

Setting this bit to 0 disables the two inverter blocks and permits overwind operation.

Parameter Range:

0 = DISABLED (overwind)

1 = ENABLED (underwind)

Default Setting:

0

Parameter Type:

Configurable

OIM Menu Path(s):

This parameter is available over the network, alternate network map,

drop_1, register 32, bit 5. It cannot be viewed through the

OIM

or

DCM

.

To use this register,

CONTROL SOURCE

SELECT must be set to

NETWORK

and

NETW REGISTER MAP

SEL

(P.914) must be set to

ALTERNATE.

The inverters are added to the speed loop block and the current minor loop reference block.

ATTENTION:

If

CONTROL SOURCE

is changed from

NETWORK

to any other control source, the

UNDERWIND ENABLE

bit is forced to the default if DISABLED. If the setting was

ENABLED

and

CONTROL

SOURCE

is changed from

NETWORK

, the motor rotates in the opposite direction when the drive is

restarted. The active speed reference should be set to zero before starting the drive from the new

control source. Slowly increase the speed reference until the proper rotation direction can be

determined. If it is incorrect, change the setting of the

FORWARD/REVERSE

input. The active speed

reference is based on the new control source and the

AUTO/MANUAL

setting.

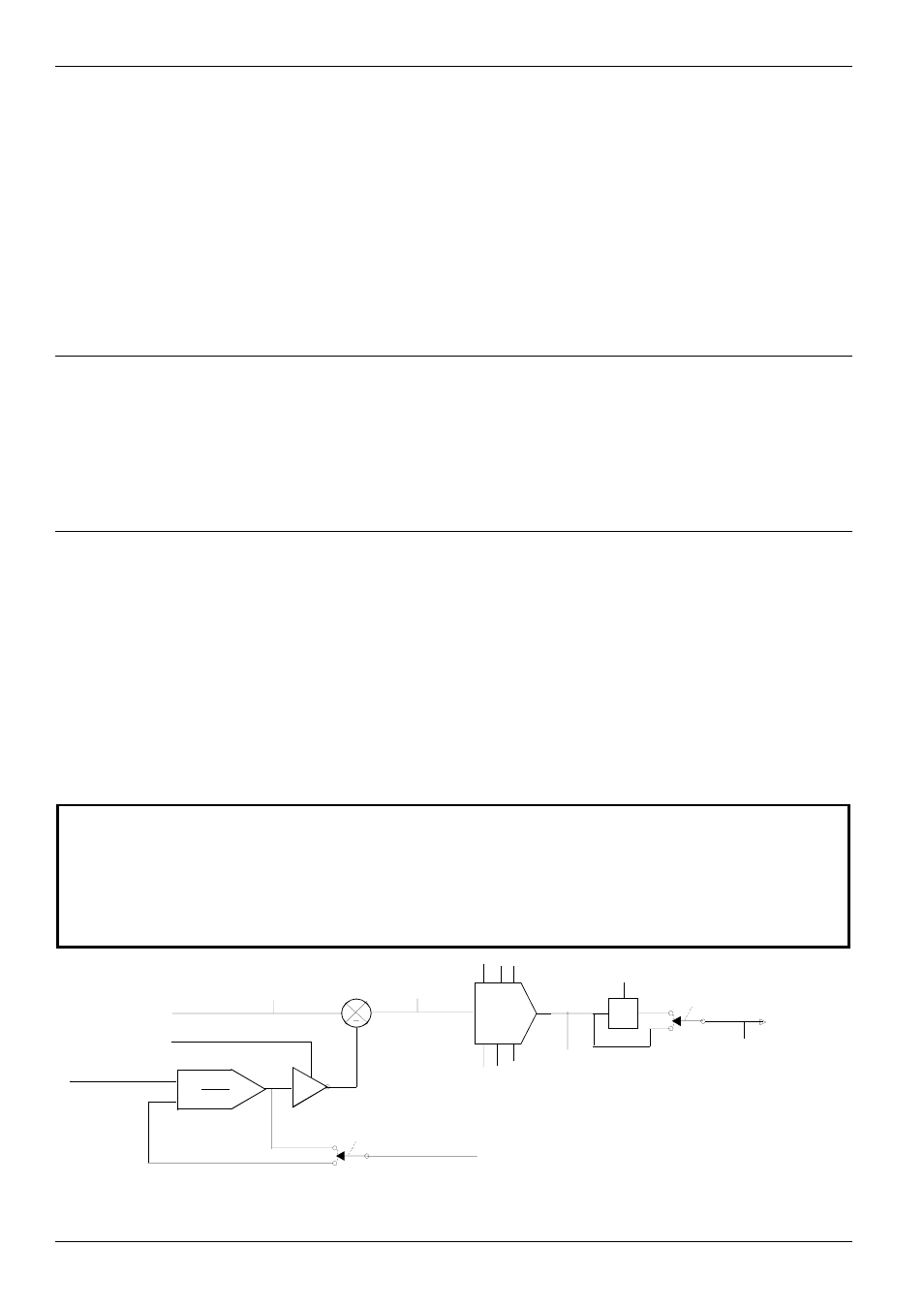

From Speed Reference

Mode Select Block Diagram

(SPD LOOP REFERENCE)

(SPD LOOP ERROR)

+

D.5(E)

P.295

P.297

MUL

IN

A * B

1000

UNDERWIND ENABLE 1)

Netw. Drop 1, Reg. 32, Bit 5

SPEED FEEDBACK GAIN 1)

Netw. Drop 1, Reg. 38

KEYPAD,

TERMBLK

or SERIAL

EN

To CML Reference

Block Diagram

(SPD LOOP OUTPUT)

PI

KP HI

WLD LO

P.299

INIT

RST

SPD LOOP LAG FREQ

SPD LOOP

LAG BYPASS

WLG

LAG

(SPD LOOP

LAG OUTPUT)

P.215

P.217

P.298

OFF

*ON

OUT

NETWORK

P.000 CSS