Troubleshooting an autotune process – Rockwell Automation 2080-LC50 Micro830 and Micro850 Programmable Controllers User Manual User Manual

Page 259

Rockwell Automation Publication 2080-UM002F-EN-E - December 2013

243

IPID Function Block Appendix F

First peak is defined as:

For Direct Operation: First peak = PV1 - (12 x Deviation)

For Reverse Operation: First peak = PV1 + (12 x Deviation)

Where PV1 is the process value when Initialize is set to FALSE.

Once the process value reaches first peak, the control output reduces by the

amount of Step and waits for the process value to drop to the second peak.

Second peak is defined as:

For Direct Operation: Second peak = PV1 - (3 x Deviation)

For Reverse Operation: Second peak = PV1 + (3 x Deviation)

Once the process value reaches or falls below second peak, calculations

commence and a set of gain will be generated to parameter OutGains

.

Troubleshooting an

Autotune Process

You can tell what is going on behind the autotune process from the sequences of

control output. Here are some known sequences of control output and what it

means if autotune fails. For the ease of illustrating the sequence of control output,

we define:

Load: 50

Step: 20

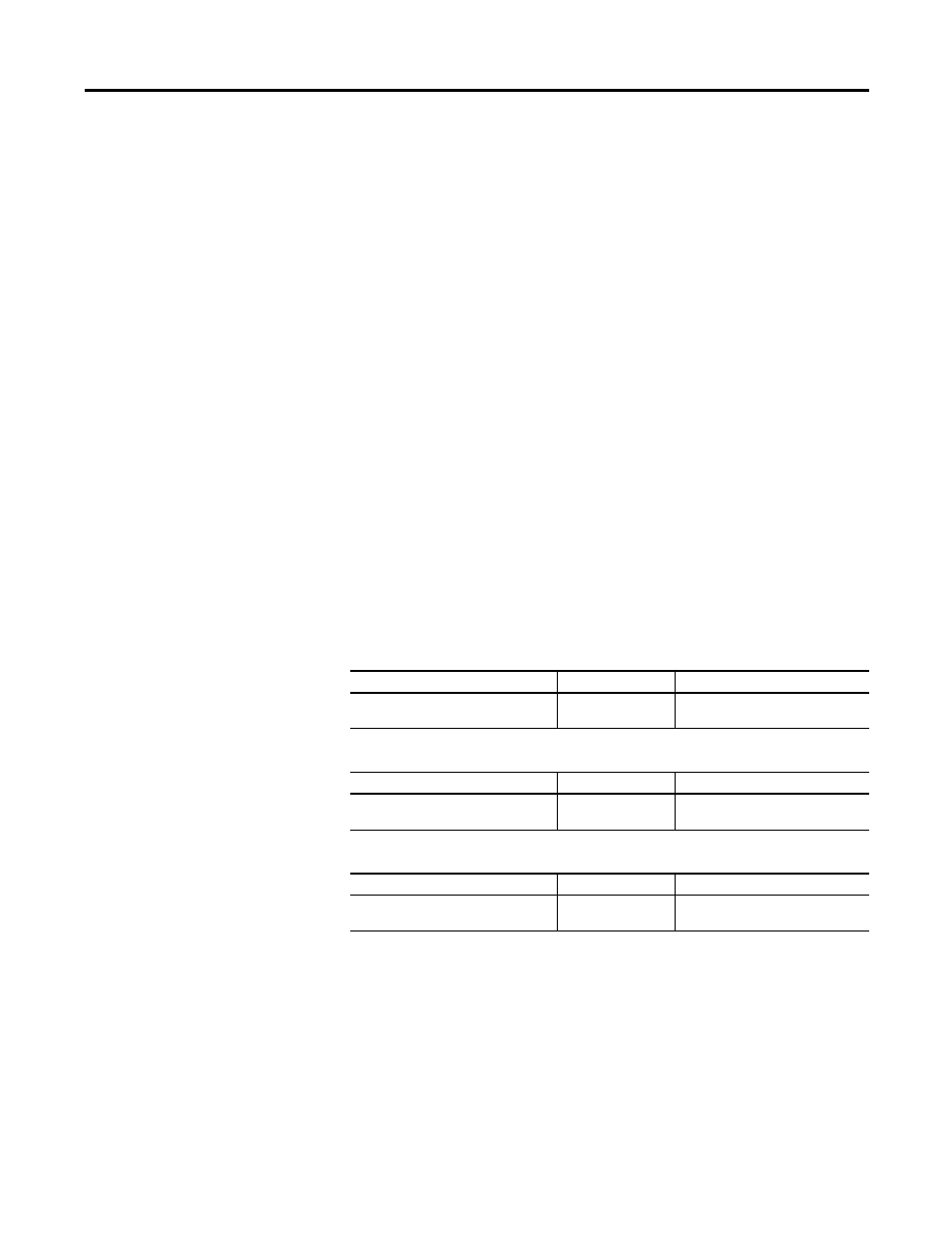

Output Sequence 1: 50 -> 70 -> 30

Sequence Condition

Autotune Result

Action for Autotune Fail

Process value reached 'first peak' and

'second' peak in time

Likely successful

NA

Output Sequence 2: 50 -> 70 -> 50

Sequence Condition

Autotune Result

Action for Autotune Fail

Process value not able to reach

'first peak'

Likely unsuccessful

Reduce Deviation or Increase Step

Output Sequence 3: 50 -> 70 -> 30 -> 50

Sequence Condition

Autotune Result

Action for Autotune Fail

Process value not able to reach

second peak

Likely unsuccessful

Increase Deviation or increase Step