Lincoln Electric IM8000 CHECKPOINT User Manual

Page 143

Summary Report

Chapter 11. Weld Listing Tab

IM8000 CheckPoint™

User

Manual

11.7

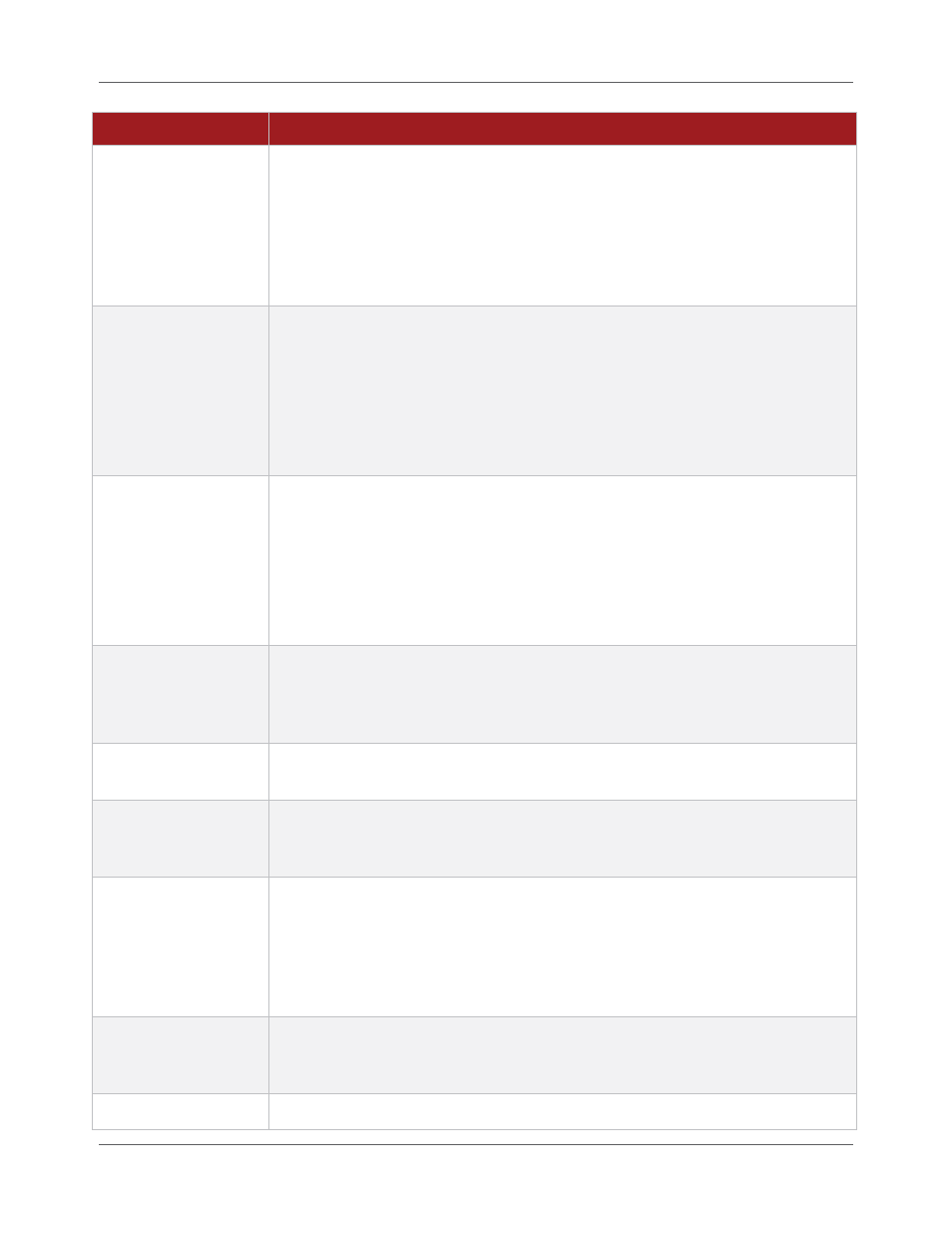

Field

Description

End Delay

This is the amount of delay used at the end of this weld. The End Delay is an

option set in the Weld Profile and is the amount of time (in seconds) directly

before the end of a weld that CheckPoint™ stops applying the limits entered for

the Weld Profile. This option is necessary because, at the end of a weld, the set

points for the Welding Power Source are often different than the rest of the weld

(e.g., if the Power Wave® is in a burn-back state). For more in-depth details on

End Delay, please refer to the Power Wave® Manager User Manual.

Wire Density

The Wire Density field in CheckPoint™ displays the density of the metal used for

this individual weld.

The person who adds the consumable to the Power Wave® uses the Power

Wave® Manager software to tell the Welding Power Source how much and what

type of wire was loaded. They select the density here as well. The system uses

the wire density in its calculation of the how much material was deposited for this

weld.

Wire Diameter

The Wire Diameter field in CheckPoint™ displays the diameter of the wire used for

this individual weld.

The person who adds the consumable to the Power Wave® uses the Power

Wave® Manager software to tell the Welding Power Source how much and what

type of wire was loaded. They enter the wire’s diameter here as well. The system

uses the wire diameter in its calculation of how much material was deposited for

this weld.

Deposited Weight

The Deposited Weight is a calculation CheckPoint™ performs for the individual

weld. Based on the metal density and diameter of the wire in the Welding Power

Source at the time of the weld, the system calculates the amount of wire (pounds

or kilograms) that was deposited during this weld.

Deposition Rate

The Deposition Rate shows how much material was deposited during the weld,

normalized to pounds per hour.

WeldScore™ Status

Weld Engineers can set each Weld Profile with a minimum WeldScore™ value that

is considered acceptable. The WeldScore™ Status field displays whether this weld

was above that score (within limits) or below that score (out of limits).

WeldScore™

The WeldScore column displays the average score for this weld. Every quarter of

a second, the Welding Power Source compares the performance of the weld

against the trained weld for the Weld Profile being used. When the weld is

complete, the power source averages those measurements together for an

average WeldScore™ value. For more details on WeldScore™, please refer to the

Power Wave® Manager User Manual.

Current Status

Weld Engineers can set each Weld Profile with a minimum and a maximum arc

current value that is considered acceptable. The Current Status field displays

whether this weld was within those limits or out of limits.

Current Minimum

The Current Minimum field displays the lowest arc current measurement taken by