Chapter 9 overall equipment efficiency (oee), Oee tab – Lincoln Electric IM8000 CHECKPOINT User Manual

Page 115

IM8000

CheckPoint™ User Manual

9.1

Chapter 9

Overall Equipment Efficiency (OEE)

Overall Equipment Efficiency (OEE) is a method for analyzing your plant’s productivity data with the intent

of helping you improve the processes at your plant. You can use the OEE calculations to determine the

effectiveness of your manufacturing processes. This includes the welders, assembly lines and operators.

This chapter explains the OEE tab in CheckPoint™ and reviews the OEE calculations and what data

CheckPoint™ uses to make those calculations.

NOTE |

The OEE features in CheckPoint™ were made available on

August 7, 2013. This is the oldest data that will display.

NOTE |

For more in-depth information on OEE, please visit check

out OEE on the web.

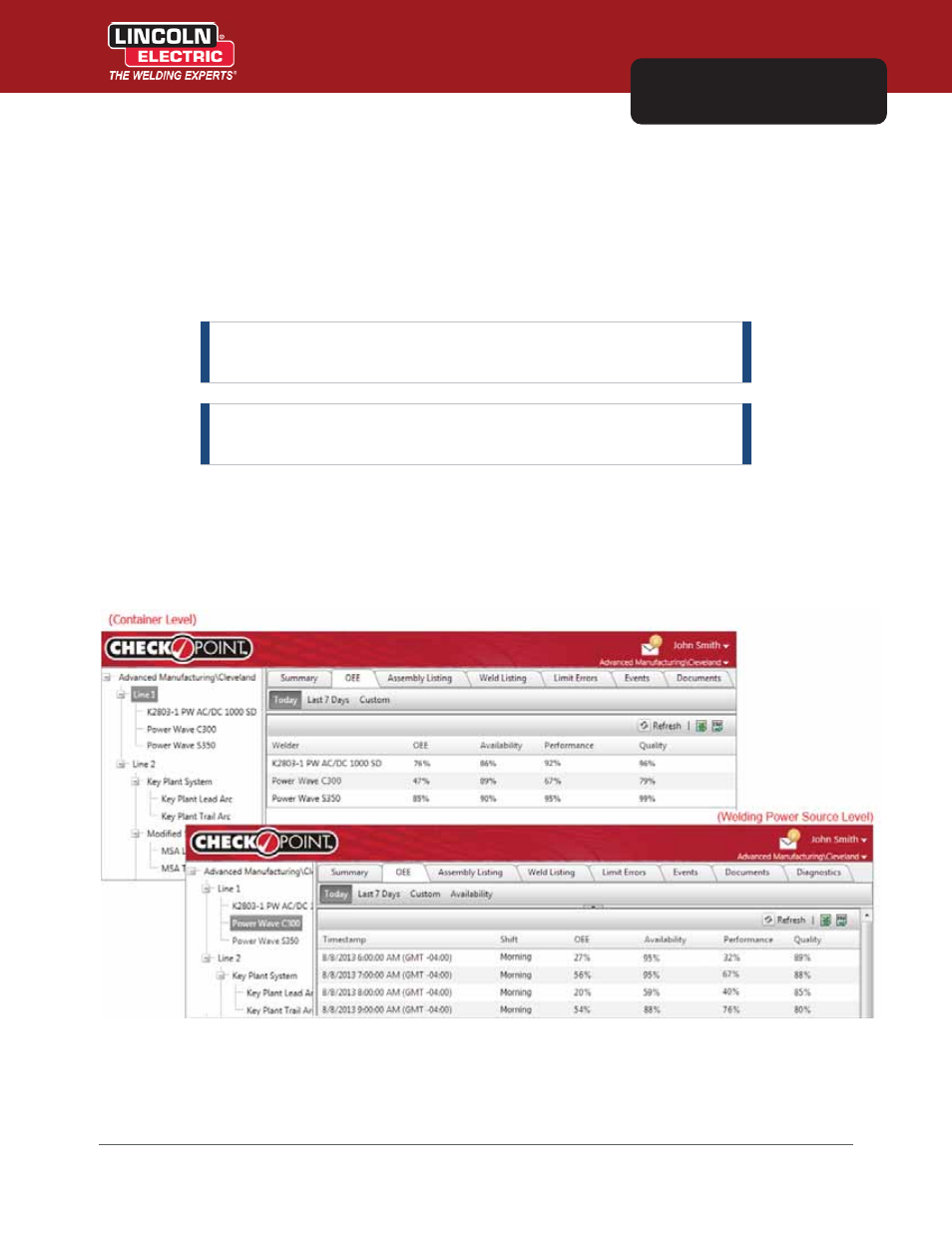

OEE Tab

On the OEE tab in CheckPoint™, you can easily view the OEE factors for a Container of power sources, as

well as drilling down to view the OEE factors for a single Welding Power Source, all the way down to the

hour of each shift. The OEE tab displays data for the asset you have selected in the Asset Tree.

Figure 9.1 OEE Tab

You can view your OEE factors for Today or the Last 7 Days using the buttons at the top of the tab. If you

would like to drill down to a specific shift on a specific day, you can use the Custom view to generate the

appropriate report.