Lincoln Electric IM8000 CHECKPOINT User Manual

Page 102

Chapter 8. Summary Tab – Power Source Level

Today

8.4 CheckPoint™

User

Manual

IM8000

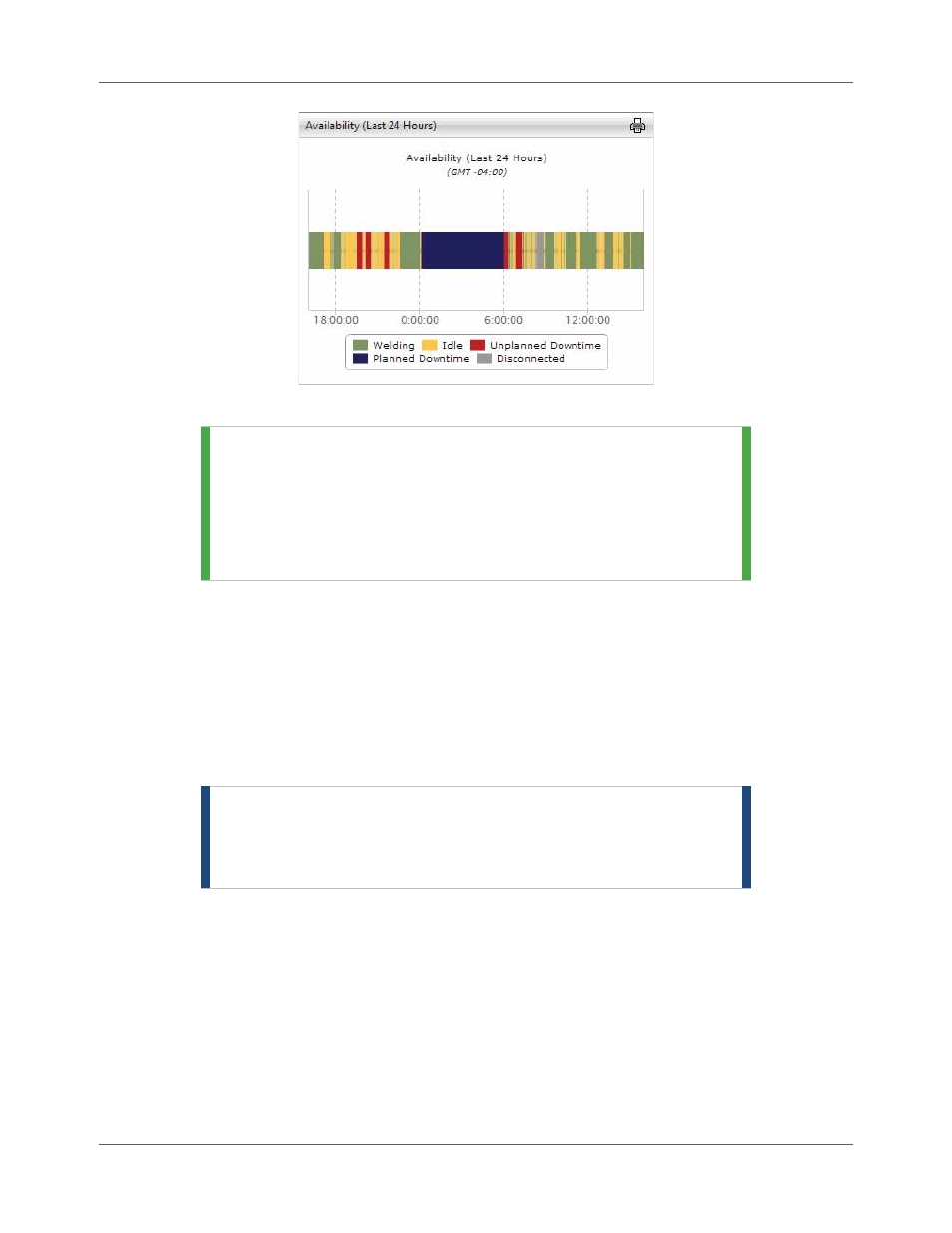

Figure 8.3 Availability (Last 24 Hours)

TIP |

For a closer look at a time period within the last 24 hours,

simply click and drag your mouse to highlight the section of

time you want to display. You can zoom down to minutes

within the last 24 hours.

Click the Reset Zoom button to go back to the initial view of

the widget.

There are several states that define the availability of a Welding Power Source and that are used in

calculating the Availability factor in OEE. You can read more about calculating the Availability factor on

page 9.5.

Welding (green): This is the amount of time during the indicated hour(s) that the selected

Welding Power Source was welding (i.e., Status = Welding). This information is included in the

calculation of Operating Time.

Idle (yellow): This is the amount of time during the indicated hour(s) that the selected Welding

Power Source was ready and able to weld, but was not welding (i.e., Status = Idle).

NOTE |

When the amount of Idle time exceeds the number in the

Idle Time Threshold field set by the CheckPoint™

administrator for this Welding Power Source, that full time

turns into Unplanned Downtime.

Unplanned Downtime (red): Unplanned Downtime is the amount of time that you expect the

welder to be welding but it cannot because it is faulted. Unplanned Downtime is subtracted

from your Planned Production Time in the Availability calculation to reach your Operating Time.

Planned Downtime (dark blue): Planned Downtime is the amount of time to be excluded from

Availability calculations because there was no intention of running production. Examples of

Planned Downtime include breaks, lunch, scheduled maintenance and other non-production

times. See page 9.10 for more in-depth details on establishing Planned Downtime in

CheckPoint™.