Lincoln Electric IM8000 CHECKPOINT User Manual

Page 142

Chapter 11. Weld Listing Tab

Summary Report

11.6 CheckPoint™

User

Manual IM8000

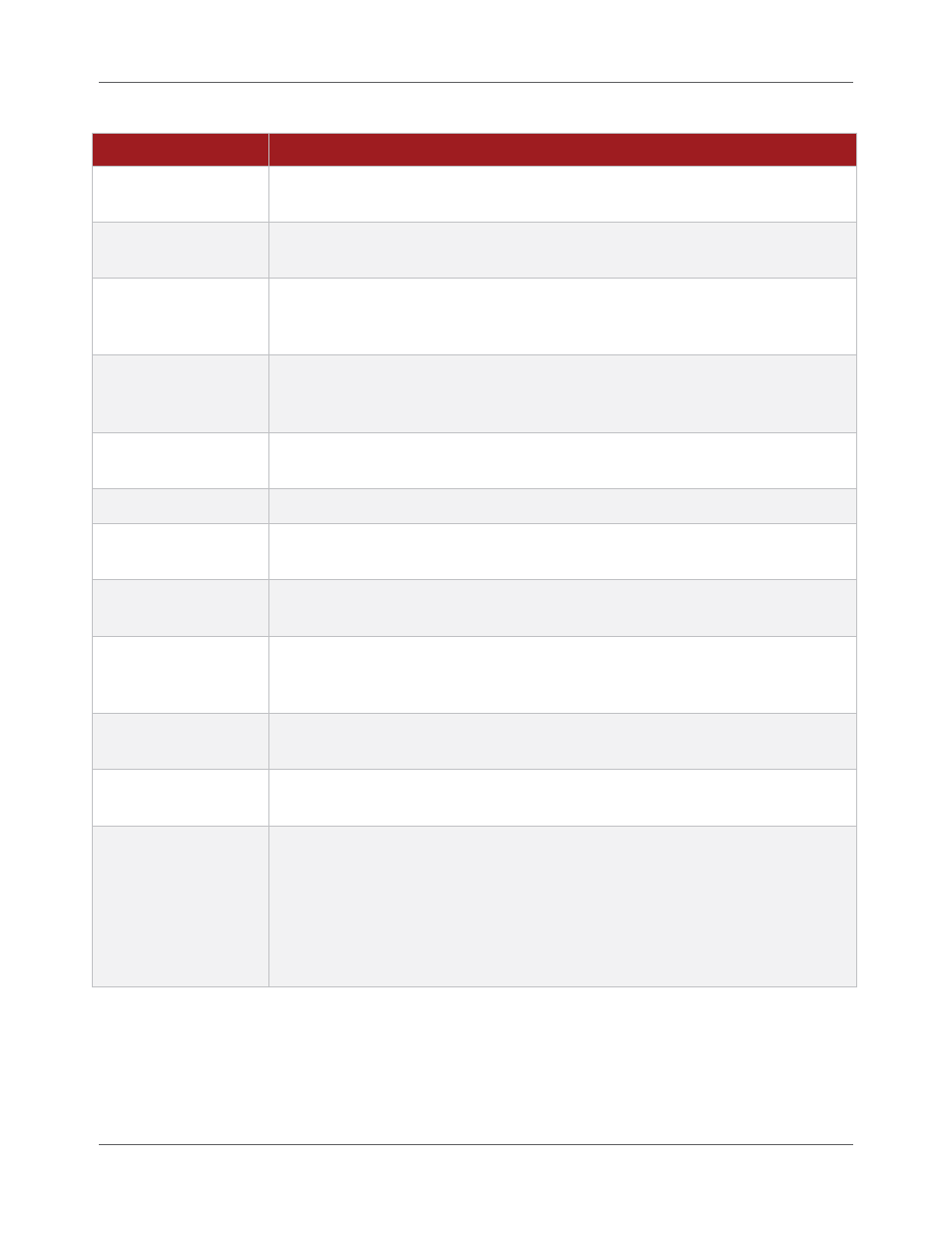

Table 11.3

Data on the Weld Detail Page

Field

Description

Welder

This column displays the name of the Welding Power Source. The CheckPoint™

administrator entered this text when creating the Asset Tree (page 4.17).

Part Assembly Name

For use with Weld Sequencer, this column displays the assembly name associated

with this weld.

Part SN

The Part SN is the part number associated with this weld. The part number

comes from a variety of sources, depending if a person enters the number in the

Power Wave® Manager manually or the information is transmitted automatically.

Operator ID

When an operator begins welding on a Power Wave®, his or her ID or badge

number is entered through Power Wave® Manager or another method. The

power source transmits that information, and CheckPoint™ displays that ID here.

Consumable Lot

The Consumable Lot is the consumable lot code that was entered into the Power

Wave® when the wire was replaced in the Welding Power Source.

Welding Power Source This is simply the Welding Power Source used for creating this individual weld.

Start of Weld

The Start of Weld column displays the date and specific time the Welding Power

Source began performing the weld.

Weld Duration

(Arc Time)

The time displayed in the Weld Duration (Arc Time) column is the length of time it

took to create the individual weld.

Duration Status

Weld Engineers can set each Weld Profile with a minimum and a maximum time

value that is considered acceptable. The Duration Status field displays whether

this weld was within those limits or out of limits.

Duration Maximum

Limit

This column simply displays the high end of the time limit that was set in the

Weld Profile used to make the weld.

Duration Minimum

Limit

This column simply displays the low end of the time limit that was set in the Weld

Profile used to make the weld.

Start Delay

This is the amount of delay that was used for the beginning of this weld. The

Start Delay is an option set in the Weld Profile and is the amount of time (in

seconds) that CheckPoint™ will wait, directly after the start of a weld, until the

limits entered for the Weld Profile begin to be applied. This option is necessary

because the start of a weld is often unpredictable and may fall out of limits easily.

For more in-depth details on Start Delay, please refer to the Power Wave®

Manager User Manual.