Lincoln Electric IM8000 CHECKPOINT User Manual

Page 122

Chapter 9. Overall Equipment Efficiency (OEE)

Calculations of OEE in CheckPoint™

9.8 CheckPoint™

User

Manual

IM8000

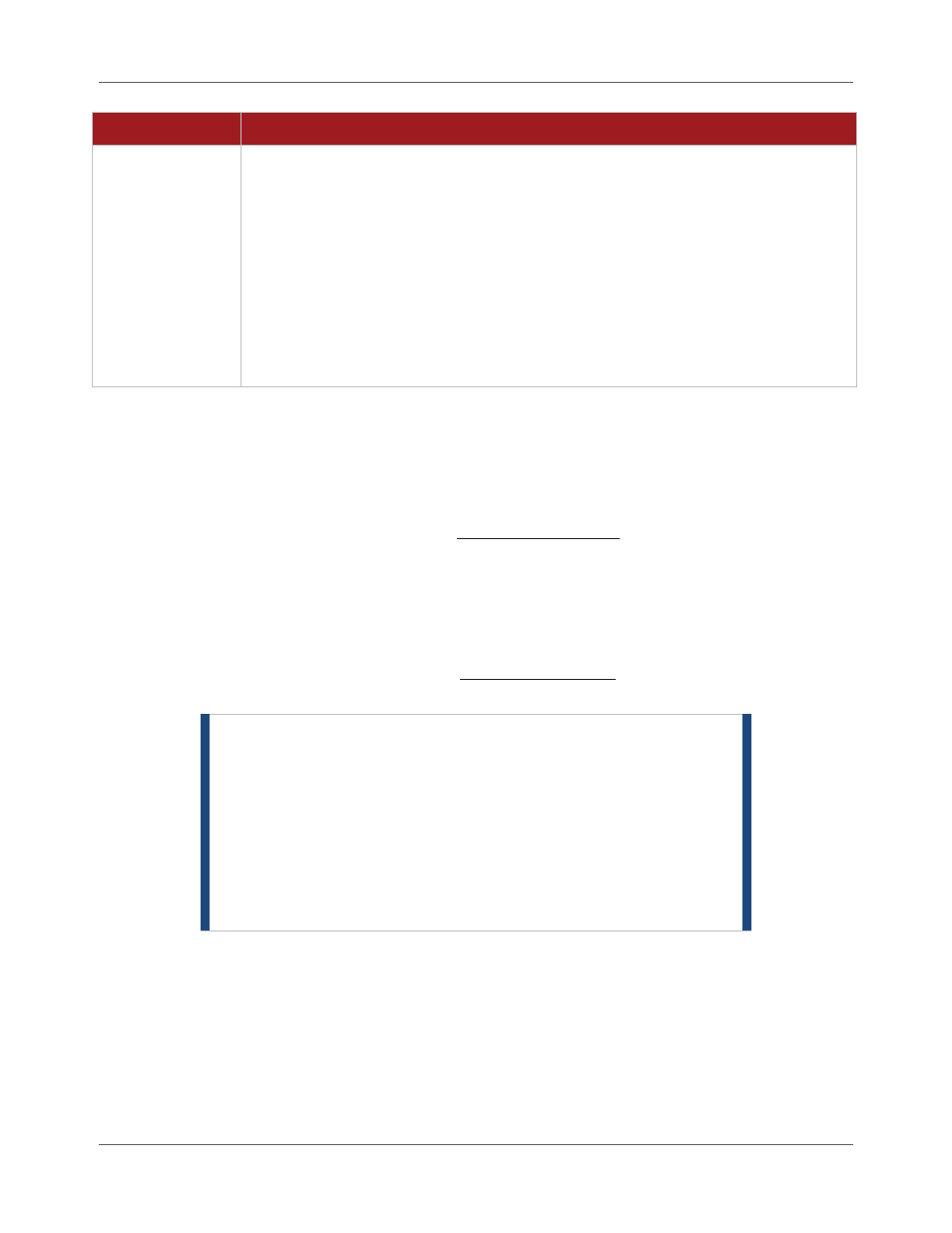

Variable

Description

Unplanned

Downtime

Unplanned Downtime is the amount of time that stops Planned Production (e.g.,

equipment failures, material shortages and changeover times). CheckPoint™

determines Unplanned Downtime using the two of the welder statuses:

Idle: When the Idle time of the welder exceeds the Idle Time Threshold set for

the welder (page 4.21), CheckPoint™ flags this as Unplanned Downtime.

Otherwise, the Idle time is not included in the Availability calculation.

Faulted: The Faulted state of a machine is automatically Unplanned

Downtime, and CheckPoint™ uses this in the Availability calculation.

The Welding and Disconnected statuses are not included in the Availability

calculation.

Performance Factor

The Performance factor compares the actual Operating Time (during the time period you select for the

report) to the Planned Operating Time for the time period you select (e.g., a month, a shift, an hour). The

OEE calculation for Performance is the following:

ܲ݁ݎ݂ݎ݉ܽ݊ܿ݁ =

ܰ݁ݐ ܱ݁ݎܽݐ݅݊݃ ܶ݅݉݁

ܩݎݏݏ ܱ݁ݎܽݐ݅݊݃ ܶ݅݉݁

CheckPoint™ calculates the Performance factor as the ratio of Arc On Time to the Planned Arc On Time.

Your CheckPoint™ administrator established the Planned Arc On Time in the Planned Arc Time Per Hour

field at the Company Site level, Container level and/or Welding Power Source level (page 4.21).

ܲ݁ݎ݂ݎ݉ܽ݊ܿ݁ =

ܣݎܿ ܱ݊ ܶ݅݉݁

݈ܲܽ݊݊݁݀ ܣݎܿ ܱ݊ ܶ݅݉݁

NOTE |

For

Arc On Time, CheckPoint™ starts with the first weld

time and ends with the last weld time for each working

segment.

For example, the time period covered in the report is

11:00 AM to 12:00 PM. The first weld performed during

that hour started at 11:03 AM and the last weld performed

began at 11:59 AM and lasted two minutes. Both welds

would be included in the Performance factor for the

11:00 AM to 12:00 PM hour.

For example, at Advanced Manufacturing, John wanted to see his Overall Equipment Efficiency (OEE)

figures for last Friday’s morning shift. He clicked the Company Site in the Asset Tree, clicked the OEE tab

and generated a custom OEE report, setting the specific date and selecting the Morning shift. To calculate

the Performance factor for the Key Plant Lead Arc (Figure 9.8), CheckPoint™ used the following data:

Shift Length: 8 hours

Planned Arc Time: Since John is just starting out with OEE, he set the Planned Arc Time Per Hour

only at the Company Site level when he set up the OEE features. He set this for 30 minutes.