Lincoln Electric IM8000 CHECKPOINT User Manual

Page 134

Chapter 10. Assembly Listing Tab

Overview Report

10.4 CheckPoint™

User

Manual IM8000

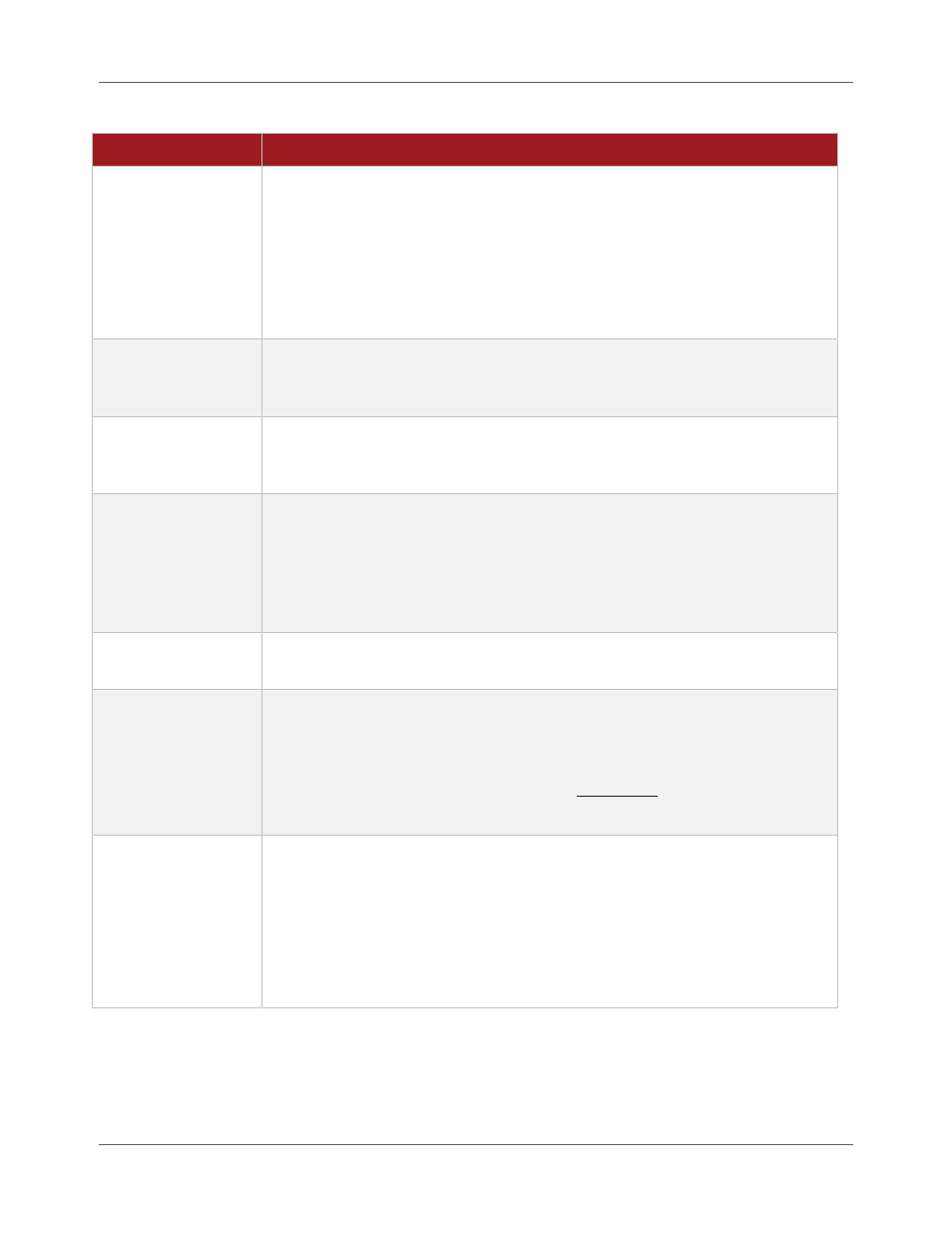

Table 10.2

Columns on the Assembly Drilldown

Field

Description

Start Time

The Start Time column reflects the date and time that the Weld Operator

clicked the Start button in Weld Sequencer for this instance of the Weld

Sequence (whether automatically at the end of the last instance of the

sequence or manually).

TIP |

Depending on the complexity of the Weld Sequence, some Weld

Sequences take longer than a single day to complete. Take this into

consideration when selecting time periods for your report.

End Time

This column displays the date and time that the Job Timer in Weld Sequencer

stops for this instance of the Weld Sequence. The Weld Operator could click

the Stop button or the sequence was aborted for some reason.

Welder

The Welder column displays only when you have a Container selected in the

Asset Tree. This column simply displays the name of the welder on which this

instance of the Weld Sequence was performed.

Cycle Time (min)

When a Weld Operator begins a sequence, they click the Start button in some

fashion (whether automatically at the end of the last one or manually). This

starts the Job Timer in Weld Sequencer. Once the Weld Operator completes

the sequence, the Job Timer stops. This is essentially how long the assembly

took to make. The Cycle Time column displays the time for this instance of the

Weld Sequence for you.

Arc Time (min)

The Arc Time column in the total arc times of the individual welds created

during this instance of the Weld Sequence.

Arc Duty Cycle

The Arc Duty Cycle is a calculation of how much time, out of the Cycle Time for

this instance of the Weld Sequence, was spent in Arc On time. CheckPoint™

provides you with a percentage using the following equation:

ܣݎܿ ܦݑݐݕ ܥݕ݈ܿ݁ =

ܣݎܿ ܶ݅݉݁

ܥݕ݈ܿ݁ ܶ݅݉݁

Welds/Expected

When a Weld Engineer creates the Weld Sequence, Weld Sequencer totals up

the number of welds expected. The Welds/Expected column displays the

current number of welds performed for this instance of the Weld Sequence,

along with the number of welds were expected.

NOTE |

If the Weld Engineer included one of the more flexible welding steps

in the sequence, the actual number of welds performed and the number of

welds expected may not match.