Lincoln Electric IM8000 CHECKPOINT User Manual

Page 121

Calculations of OEE in CheckPoint™

Chapter 9. Overall Equipment Efficiency (OEE)

IM8000 CheckPoint™

User

Manual

9.7

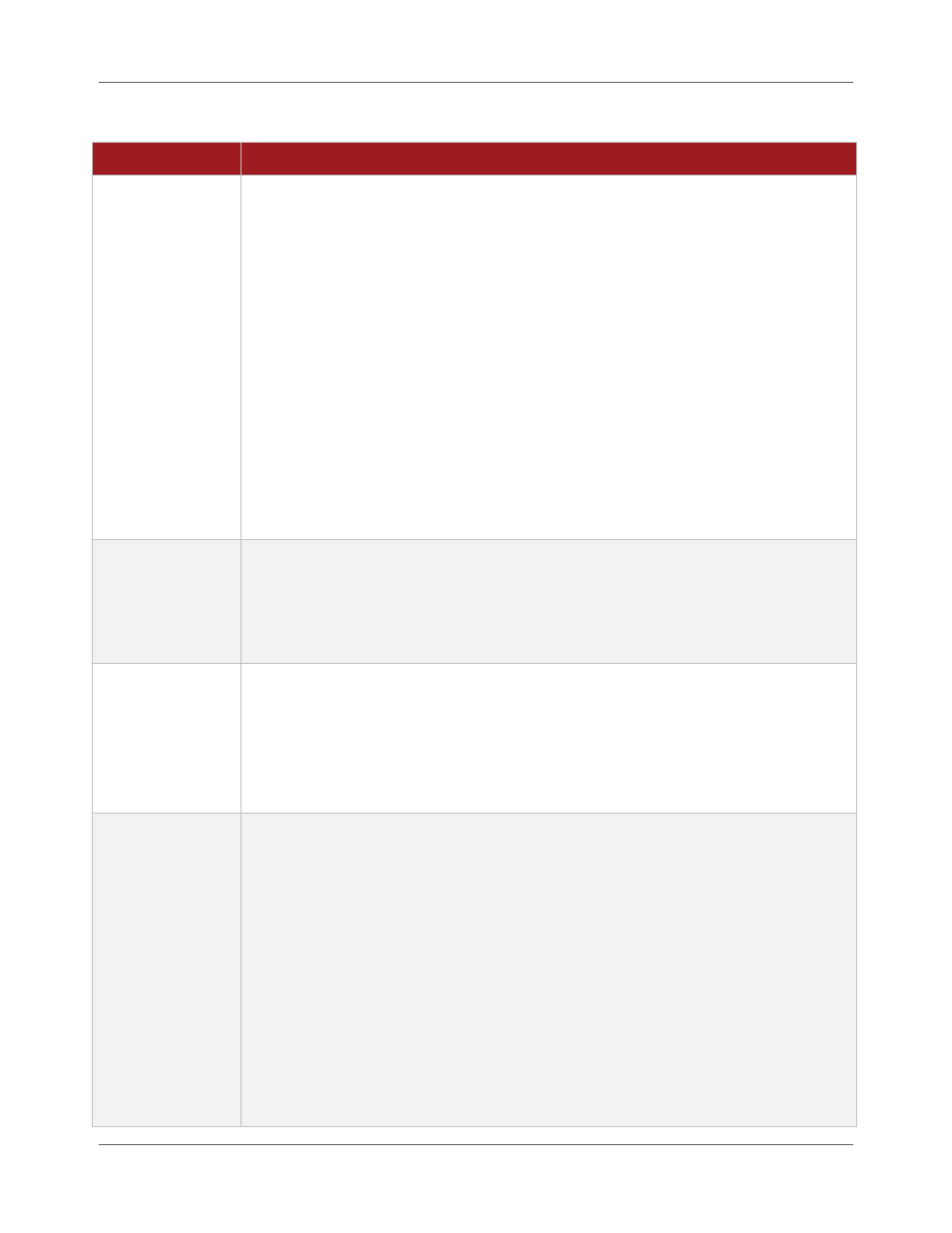

Table 9.2

Variables in Availability

Variable

Description

Asset Scheduled

Time

The Asset Scheduled Time in CheckPoint™ is any time when there is no Planned

Downtime. If your company has no Planned Downtime entered at the Company Site,

Container or Welding Power Source level (page 9.10), CheckPoint™ considers the

asset scheduled and productive 24 hours a day, 7 days a week, 365 days a year.

In order to calculate the Asset Scheduled Time accurately, CheckPoint™ must remove

any time the Welding Power Source(s) spent in the Disconnected status. There is no

way to know if the machine(s) was/were welding, faulted, etc.

ܣݏݏ݁ݐ ݄ܵܿ݁݀ݑ݈݁݀ ܶ݅݉݁ = ܶ݅݉݁ ܲ݁ݎ݅݀ െ ܦ݅ݏܿ݊݊݁ܿݐ݁݀ ܶ݅݉݁ ܦݑݎ݅݊݃ ܶ݅݉݁ ܲ݁ݎ݅݀

For example, for an eight-hour shift (480 minutes), the Welding Power Source was

disconnected for 108 minutes. The Asset Scheduled Time for this Welding Power

Source is 480 minutes minus 108 minutes for a total of 372 minutes to be used in the

Availability calculation.

NOTE |

If

the

Asset Scheduled Time is zero (i.e., the Welding Power Source(s)

was/were disconnected the entire time period), the Availability factor is 0%.

Operating Time

Operating Time is the amount of time the machine or asset is actually working. You

reach this figure by subtracting any Unplanned Downtime from the amount of time

you expect the machine or asset to be working.

ܱ݁ݎܽݐ݅݊݃ ܶ݅݉݁ = ݈ܲܽ݊݊݁݀ ܲݎ݀ݑܿݐ݅݊ ܶ݅݉݁ െ ܷ݈݊ܽ݊݊݁݀ ܦݓ݊ݐ݅݉݁

Planned

Downtime

Planned Downtime is the amount of time to be excluded from efficiency calculations

because there was no intention of running production. Examples of Planned

Downtime include breaks, lunch, scheduled maintenance, holidays and other non-

production times.

Your CheckPoint™ administrator entered the Planned Downtime for the Company

Site, Container and Welding Power Source in the CheckPoint™ Manager (page 9.10).

Planned

Production Time

Planned Production Time is the amount of the time you expect the machine or asset

to be working. There are two components to Planned Production Time: Asset

Scheduled Time and Planned Downtime. You reach this figure by subtracting any

Planned Downtime from the amount of time you expect the machine or asset to be

working—it’s “scheduled time”.

݈ܲܽ݊݊݁݀ ܲݎ݀ݑܿݐ݅݊ ܶ݅݉݁ = ܣݏݏ݁ݐ ݄ܵܿ݁݀ݑ݈݁݀ ܶ݅݉݁ െ ݈ܲܽ݊݊݁݀ ܦݓ݊ݐ݅݉݁

CheckPoint™ considers a Welding Power Source as “scheduled” unless there is a

Planned Downtime event listed for the Welding Power Source (page 9.15). If there

are no Planned Downtime events listed for the Welding Power Source(s), it is

considered scheduled 24 hours a day, 7 days a week, 365 days a year.

NOTE |

If

the

Planned Production Time is zero (where the Asset Scheduled Time

equals the Planned Downtime), the Availability factor is 0%.