Lincoln Electric IM8000 CHECKPOINT User Manual

Page 101

Today

Chapter 8. Summary Tab – Power Source Level

IM8000

CheckPoint™ User Manual

8.3

TIP |

The information icon ( ) in the corner of the widget

provides a handy legend of the background colors.

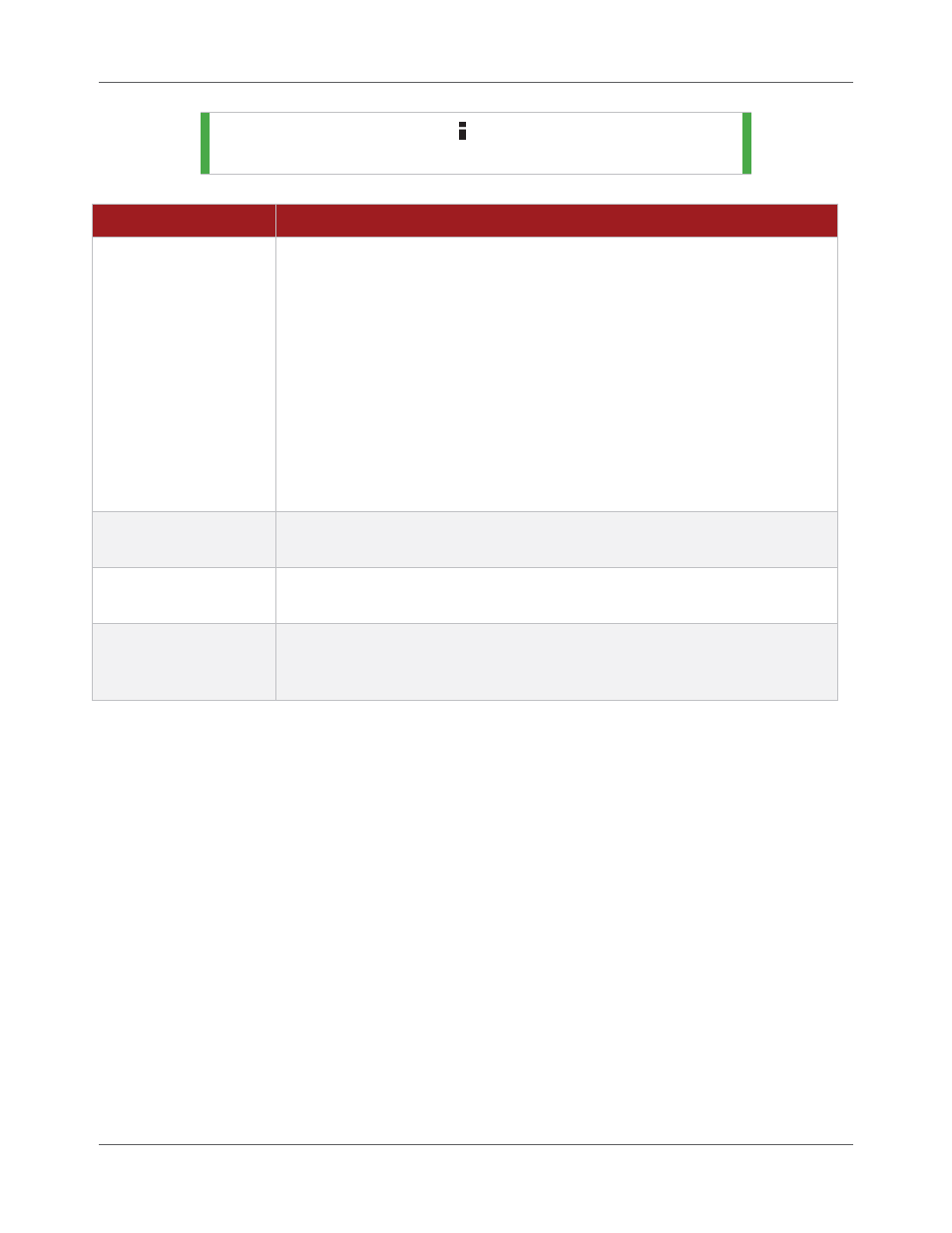

Table 8.1

Data Points on the Status Widget

Field

Description

Time Since Last Weld

or Arc Time

The first data point on the status widget displays depending on if the Welding

Power Source is currently welding.

Time Since Last Weld: If the Welding Power Source is either Idle or

Faulted, the text is Time Since Last Weld. This is the amount of time

since the most recent weld was performed by the Welding Power

Source, based on the start time of the weld.

Arc Time: If the Welding Power Source is currently performing a weld

(i.e., Status = Welding), the text displayed is Arc Time. This is amount

of time the Welding Power Source has currently been welding. Some

welds take several minutes or even hours to complete. The Arc Time

tells you how long the welder has been actively welding the current

weld.

Welds (24 hrs)

This displays the total number of individual welds performed by the Welding

Power Source over the last 24 hours from the current time.

Arc Time (24 hrs)

This displays the total number of hours that the Welding Power Source spent

welding over the last 24 hours from the current time.

Wire Remaining

This displays the amount of wire (in pounds or kilograms) remaining in the

current wire package for the Welding Power Source. Refer to the Power

Wave® Manager User Manual for setting up wire package information.

Availability (Last 24 Hours)

The Availability (Last 24 Hours) graph is mainly for use with Overall Equipment Efficiency (OEE), and it

shows you visually the amount of time the selected Welding Power Source has been available for welding

(or not available) over the last 24 hours, including any Planned Downtimes and Unplanned Downtimes.

Based on this information, CheckPoint™ can accurately calculate your OEE. OEE is a method for analyzing

your plant’s productivity data with the intent of helping you improve the processes at your plant. Even if

you aren’t using OEE, the Availability graph can still provide you with useful information on the times the

Welding Power Source spent in the Welding, Idle, Faulted (i.e., Unplanned Downtime) or Disconnected

states.