Lincoln Electric IM8000 CHECKPOINT User Manual

Page 123

Calculations of OEE in CheckPoint™

Chapter 9. Overall Equipment Efficiency (OEE)

IM8000 CheckPoint™

User

Manual

9.9

Each Welding Power Source reflects this same Planned Arc Time Per Hour. The Planned Arc On

Time for the entire shift is 8 hours x 30 minutes per hour, or 240 minutes.

Arc On Time: The total Arc On Time for the shift is the total Arc Time of the welds during that

shift, which was 185.46 minutes.

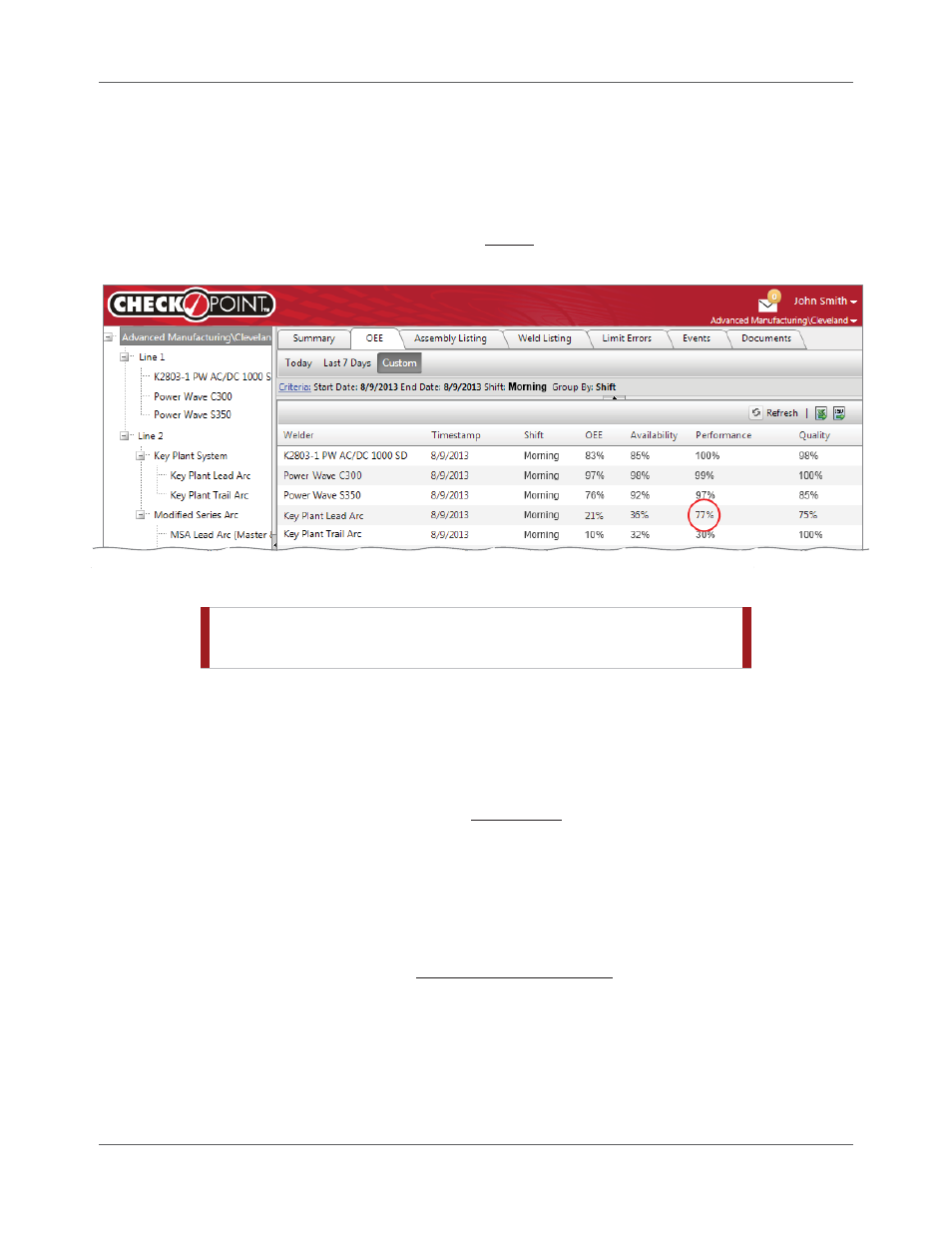

ܲ݁ݎ݂ݎ݉ܽ݊ܿ݁ =

185.46

240

= 77%

Figure 9.8 Performance Example

STOP |

If the CheckPoint™ administrator does not specify Planned

Arc Time Per Hour, the Performance factor will be 0%.

Quality Factor

The Quality factor in OEE takes into account Quality Loss, which accounts for produced pieces that do not

meet your quality standards, including pieces that require rework. The remaining time is called Fully

Productive Time. Our goal is to maximize Fully Productive Time.

ܳݑ݈ܽ݅ݐݕ =

ܩ݀ ܲ݅݁ܿ݁ݏ

ܶݐ݈ܽ ܲ݅݁ܿ݁ݏ

CheckPoint™ helps you monitor acceptable welds and flag those you consider unacceptable with limits you

set in the Weld Profiles and welds you train for WeldScore™. (See the Power Wave® Manager User

Manual.) CheckPoint™ uses your limits and WeldScore™ to determine the Quality factor. CheckPoint™

calculates the Quality factor for OEE using the following formula:

ܳݑ݈ܽ݅ݐݕ =

ܵݑ݉ ݂ ܰݎ݈݉ܽ݅ݖ݁݀ ܮ݅݉݅ݐݏ

ܶݐ݈ܽ ܮ݅݉݅ݐݏ ܧܾ݈݊ܽ݁݀

The Sum of Normalized Limits is the number of limits that were enabled AND where the limit for the weld

was within the parameters established in the Weld Profile for that weld. Each limit that meets both

conditions is counted as “1”. If the limit was enabled, but the weld was outside those parameters, the

number is “0”. The Sum of Normalized Limits in Table 9.3 would be “5.96”.