7 zero gas cylinder (part no. g7001zc), 2 piping for the calibration gases – Yokogawa Multi Channel Oxygen Analyzer System ZR22/AV550G User Manual

Page 77

IM 11M12D01-01E

4-11

4. Piping

4.2.2

Piping for the Calibration Gases

The piping for the calibration gases should be installed between the calibration gas

cylinders (or instrument air source) and the detectors with a flowmeter, solenoid valves,

needle valves, and stop valves for performing automatic calibration.

• Place the calibration gas cylinders in a place not exposed to direct sunlight as much as

possible, e.g., house in a gas unit case. The cylinder should be equipped with a

pressure reducing valve (Yokogawa recommended part) and where necessary, a stop

valve.

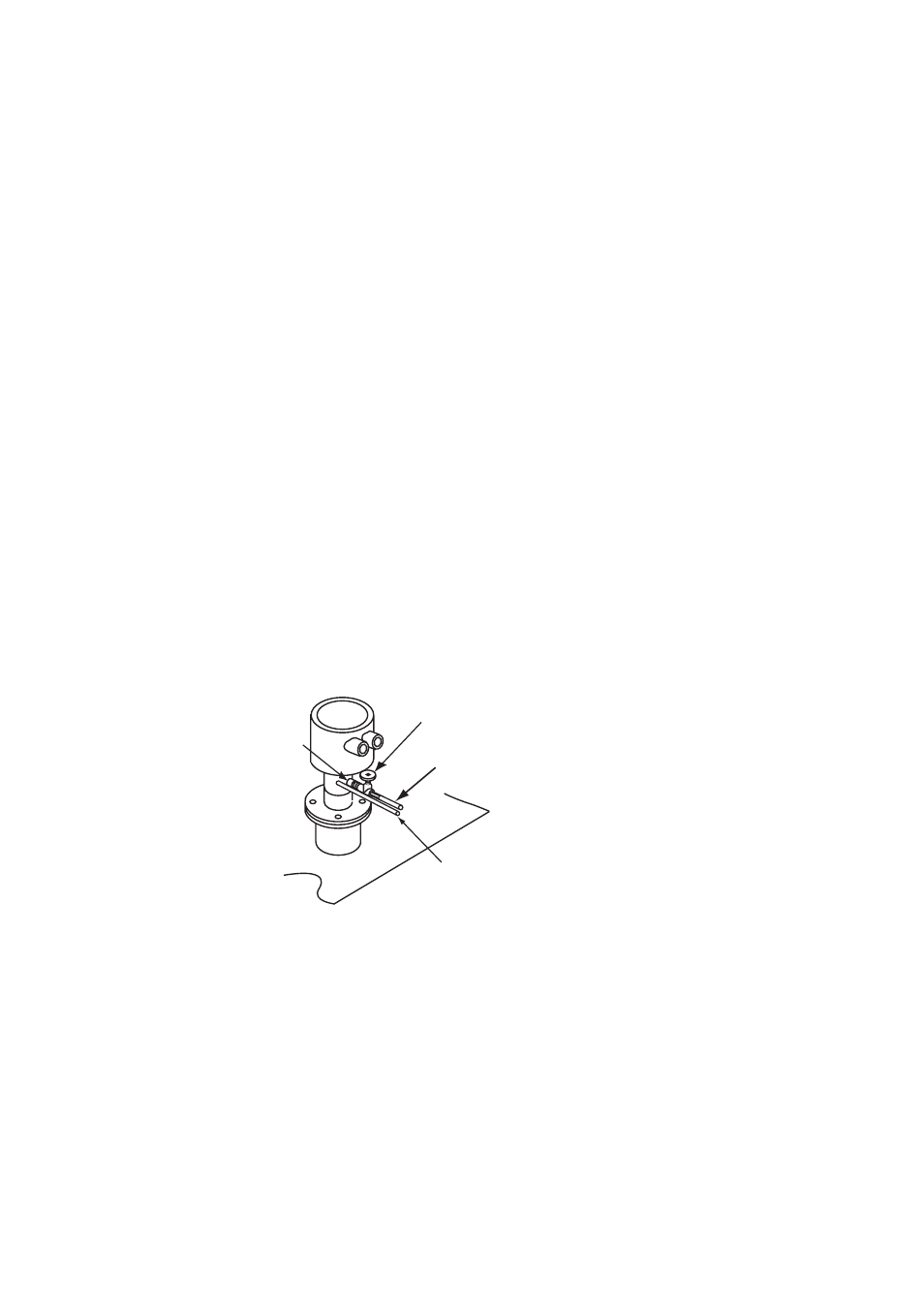

• Install a normally closed solenoid valve (Yokogawa recommended part) through a

nipple (commercially available) on the calibration gas inlet of the detector as shown

in Figure 4.11. This solenoid valve is activated by a contact signal from the averaging

converter. (Power wiring is separately required.)

Note: If the solenoid valve cannot be connected directly to the calibration gas inlet of

the detector, install a dedicated check valve (K9292DN or K9292DS) on the

inlet and then route the piping to the solenoid valve.

• After installing the solenoid valve on the calibration gas inlet of the detector, route the

piping through a flowmeter, a needle valve, a solenoid valve for switching zero and

span gases, a stop valve, and a pressure reducing valve for the cylinder, in this order,

to the cylinder.

• Install the piping for the solenoid valve for switching zero and span gases so that the

zero gas is introduced to the detector when powered. This solenoid valve is activated

by a contact signal from the averaging converter. (Power wiring is separately

required.)

• Install the needle valve and flowmeter in close proximity as much as possible.

• Use stainless steel pipes with 6 OD x 4 ID mm (or nominal 1/4 inch) or larger inside

diameter for the piping for the calibration gases.

F4202.EPS

Solenoid valve (nomal close)

Connect directly to piping inlet

Calibration gas piping

л

6

ϫ л

4mm stainless steel pipe

Reference gas piping

л

6

ϫ л

4mm

(or nominal 1/4-inch) stainless steel pipe

Nipple

Figure 4.11 Piping for the Calibration Gas Inlet