5 check valve (part no. k9292dn or k9292ds), 4 mounting of the high-temperature detector, Figure 4.9 typical piping for purging – Yokogawa Multi Channel Oxygen Analyzer System ZR22/AV550G User Manual

Page 74

IM 11M12D01-01E

4-8

4.1.7

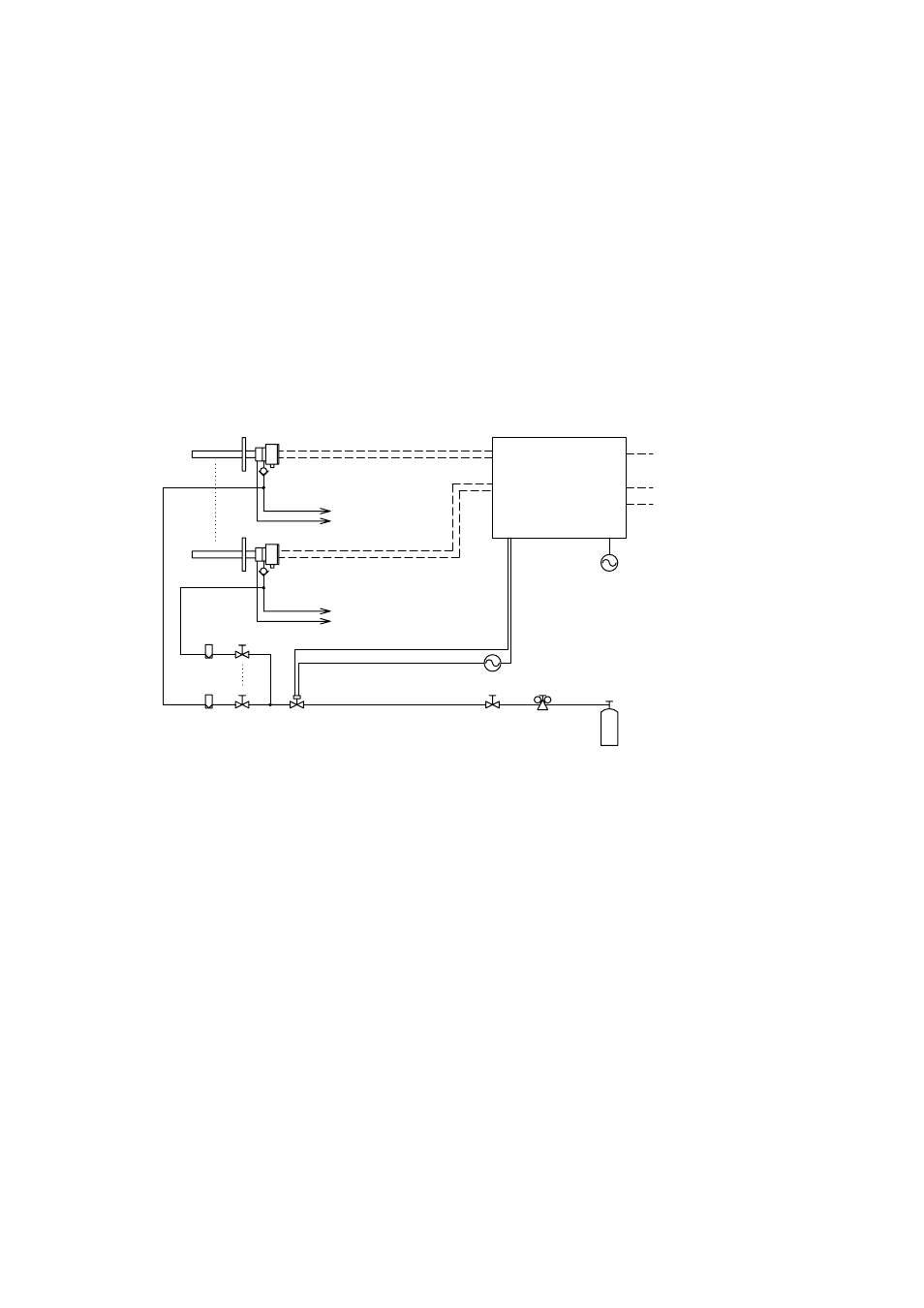

Piping to Introduce Purge Gas When a Process Gas Alarm Occurs

When a process gas alarm (an input contact signal of unburnt gas detection) occurs, the

averaging converter will cut off the power supply to the heater of the detector, and at the

same time it will send a contact output to activate a solenoid valve for introducing a

purge gas to the detector.

In addition to the system configuration shown in Figure 4.1, a purge gas cylinder and a

pressure reducing valve, and where necessary, a stop valve, a flowmeter, and a needle

valve are required. Also, a check valve should be installed on the calibration gas inlet of

the detector. A typical piping diagram for purging is shown in Figure 4.9.

It is recommended that each instrument be installed to allow for minimum piping

between the ZA8F Flow Setting Unit and the detector and between the solenoid valve

for introducing the purge gas and the detector.

Check valve

Check valve

To ZA8F

Calibration gas line

Reference gas line

To ZA8F

Averaging Converter (AV550G)

Heater

Signal

Contact output

purging gas cylinder

Flowmeter

Pressure regulator

Needlu valve

Reference gas line

Calibration gas line

Solenoid valve

Detector

Power supply

Contact input

Contact output

Analog outputs:

(Averaged and individual outputs)

Stop valve

Figure 4.9 Typical Piping for Purging