2 installation of the detector (model zr22g-015), 1 installation location, 5 pipinf for blowback – Yokogawa Multi Channel Oxygen Analyzer System ZR22/AV550G User Manual

Page 72

IM 11M12D01-01E

4-6

4.1.5

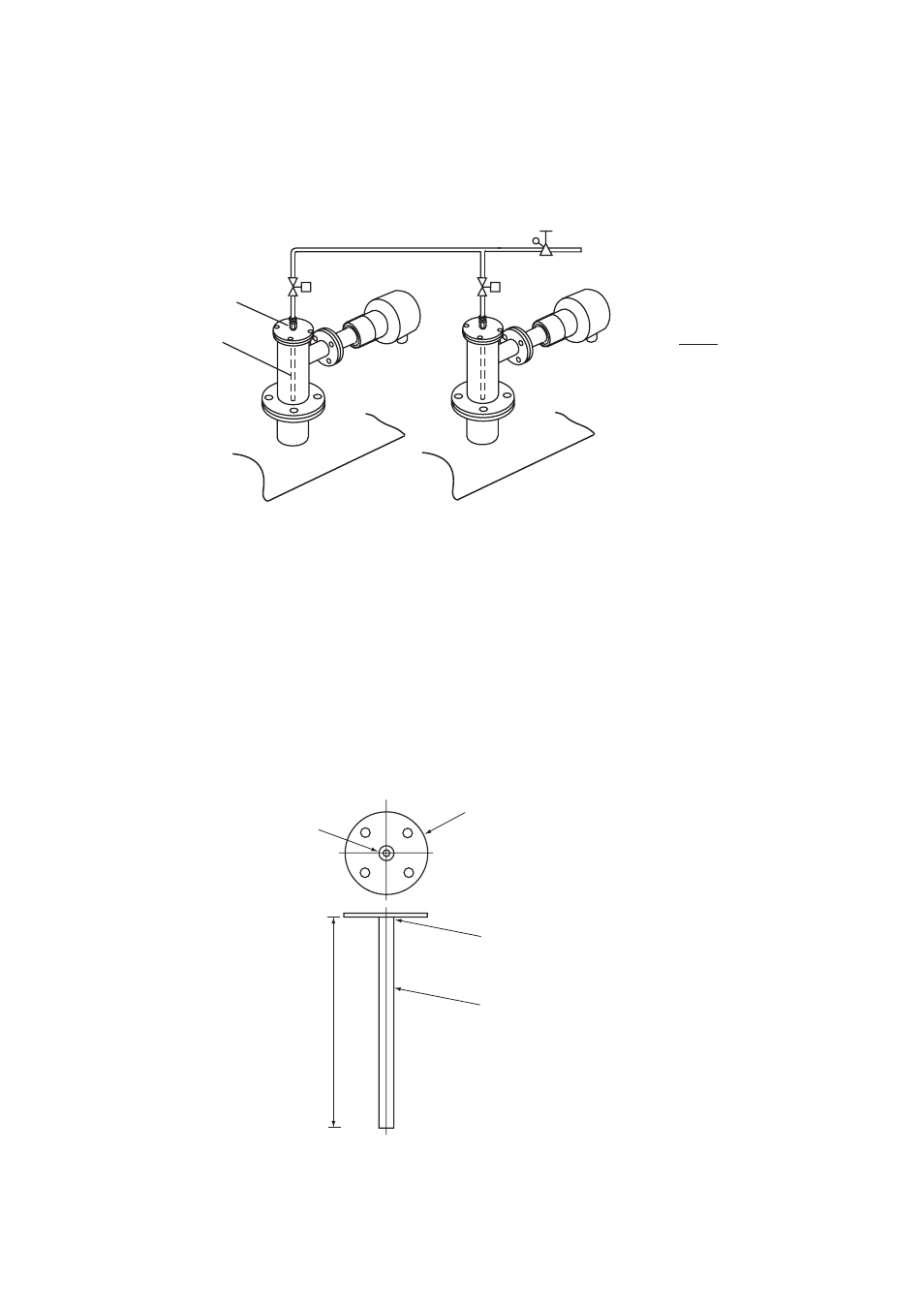

Pipinf for Blowback

This piping is required when the blow back function is carried out. The piping described

below provides automatic blow back operation when the “ blow back start “ command is

entered to the converter.

Pipe coupling

Blow pipe

Blowback air

Regulator valve

F4302.EPS

Solenoid valve

Solenoid valve

If blowback is done under control of a

contact output from the averaging

converter, a hold is placed on analog

output signals from all detector while

blowback is in progress.

See Section 10.5 for details on the

blowback function. Wiring for solenoid

valves is described in Section 5.3.

Note

Figure 4.6 Blowback Piping

The following parts are required for blow back piping.

• Blow pipe (to be prepared as illustrated in Figure 4.7.)

• Two-way solenoid valve: “ Open “ when electric current is on. (Found on the open

market)

• Air set (recommended by YOKOGAWA, G7011XF / E7040EL or G7004XF / K9473XG)

temperature probe adapter.

Approximately

200

Rc1/4

Blind flange of the adapter for

high temperature probe

Welded

8 (O.D.) by 6 (I.D.) Stainless steel pipe

F4.11E.EPS

Unit : mm

Figure 4.7 Blow pipe Construction