A conceptual view of the rm system, What is an instance, Functions – Watlow EZ-ZONE RME User Manual

Page 9

Watlow EZ-ZONE

®

RME Module

•

6

•

Chapter 1 Overview

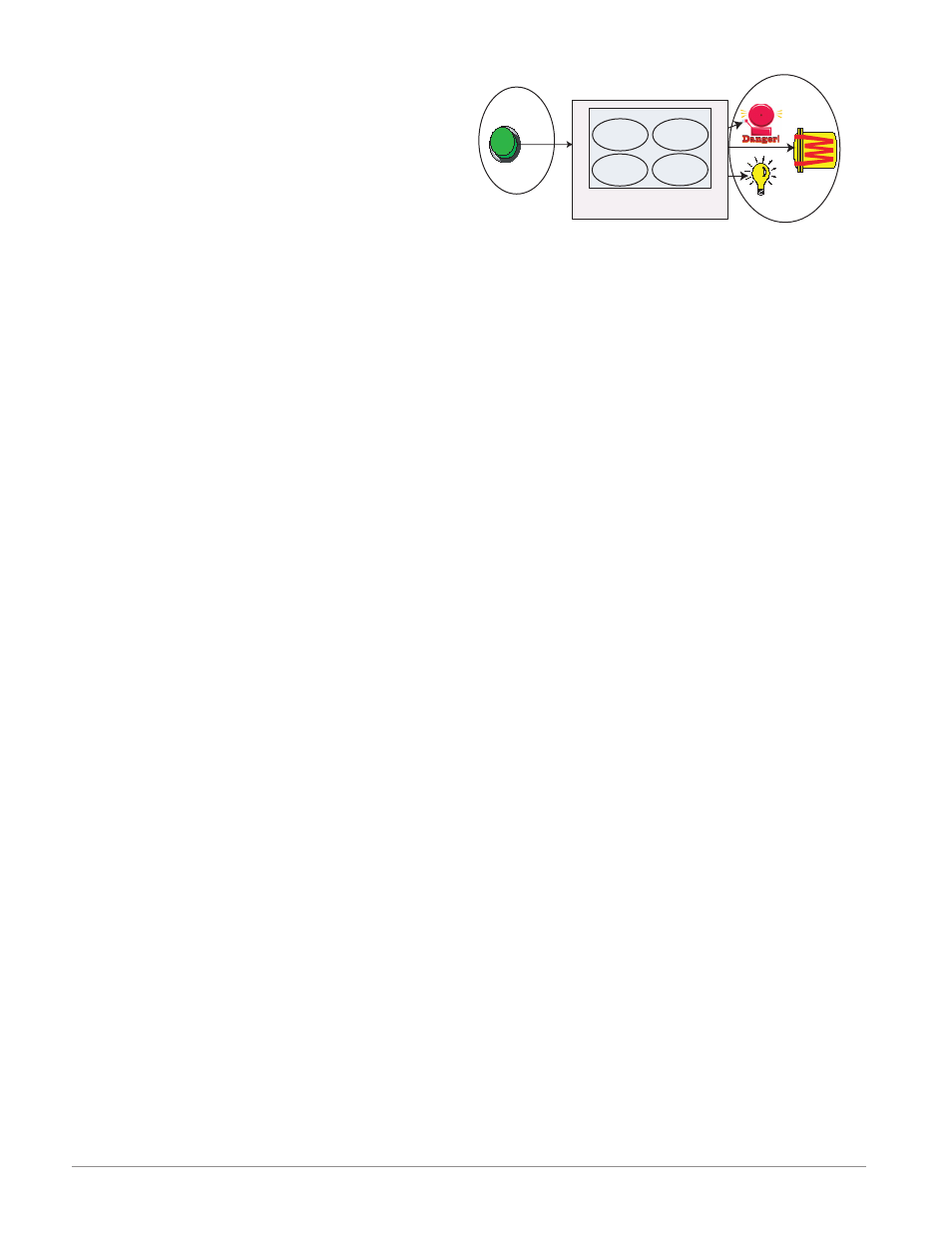

A Conceptual View of the RM System

The flexibility of the RM system software and hard-

ware allows for a large range of configurations. Fo-

cusing on the RME module, acquiring a better under-

standing of its overall functionality and capabilities

while at the same time planning out how this module

can be used will deliver maximum effectiveness in

your application.

The RM system at a high level can have a total

of 17 modules installed, one of which can be an Ac-

cess module and the others (16 maximum) can be any

combination of available RM modules. Each installed

RM module must have a unique Standard Bus ad-

dress ranging from 1-9, A-F, H (10 -16). The Access

module will be delivered with a default Standard Bus

address of 17 (J). If not using the default zone ad-

dress the user will need to define each zone address

via the button on the face of each module.

The RME can be considered an accessory RM

module in that by itself it has no PID control loops.

However, used in conjunction with an RM Control-

ler (RMC) or RM High Density (RMH) module the

RME provides increased I/O capabilities. Outputs of

the RME can be used to drive output loads of various

kinds. For instance, an RME module could be placed

in a remote location (up to 200 feet away) from a PID

controller such as an RMC or RMH to drive a heater.

Some of the user selectable ordering options are

listed below:

1. Class 2 or SELV (Saftey Extra Low Voltage) equiv-

alent Power Supplies:

• 90-264 Vac to 24Vdc @ 31 watts

• 90-264 Vac to 24Vdc @ 60 watts

• 90-264 Vac to 24Vdc @ 91 watts

2. RM Expansion Module can provide:

• 1 to 24 Digital Inputs/Outputs (I/O)

• 4 to 12 Form A Mechanical Relays

• 2 to 4 Form A 10A Solid-State Relays

• 4 inputs for external Current Transformers

(CT)

When using this module, either as a stand-alone

module or used in conjunction with any other RM

module it is useful to remember that each process

needs to be thought out carefully and the controller’s

inputs, functions and outputs configured properly.

Note:

Zones can communicate with one another over the

backplane (local and split rail). Once the system is

configured and running changing zone addresses

without careful deliberation may cause disruption in

operation.

Functions

Outputs

Process

Alarm

High

*PID

Heat

Power

Sequencing

Outputs

Silence

Alarms

Inputs

* Output is driven from another

RM PID controller module

What is an Instance?

The RM system can have many I/O points, in some

cases, as described above, I/O can be placed in re-

mote locations. For example, an RME module can

have 24 digital I/O where each would be numbered

from 1 to 24 and each would be considered a unique

instance. They are named Digital I/O 1, 2, 3, etc...

These instance numbers are then used when you

link inputs, functions and outputs within a module

or when linked to other modules. For example, when

configuring an RME output for heat the control loop

instance (1, 2, 3 or 4) and zone (1 to 16) to drive the

output must be defined.

Functions

Functions, in simple terms, use input signals (real-

world or internal), to calculate a value and deliver an

output. A function may be as simple as configuring

the function of the digital output, e.g., alarm, heat,

etc..., or defining a set point for an alarm state to

turn on or off.

To set up a function, one of the first things that

must be considered is the function source and in-

stance. For example, if the control is equipped with

Digital Inputs (source) and it was decided to use DI

9 (instance) it can then be associated with an Action

to reset an individual alarm or all alarms. The steps

below, walk through this configuration:

Setup Page (Digital I/O Menu)

1. Navigate to the Setup Page and then to the Digital

I/O menu.

2. Select the desired instance and set the direction to

input voltage or input dry contact.

Setup Page (Action Menu)

3. Navigate to the Setup Page and then the Action

menu.

4. Set the Action Function to Alarm

5. Select which alarm instance will be reset (0 equals

all)

6. Select the Source Function to Digital I/O

7. Select the Source Instance (step 2 above)

8. Select the Source Zone (0 equals the module being

configured).

9. Select the Active Level to execute the desired func-

tion.

When the selected digital input is active the alarm or

all alarms that are latched without a currently exist-

ing alarm condition will be reset. If a specific alarm

instance (1 - 8) is selected (step 5 above), it will be