Saving and restoring user settings, Inputs, Outputs – Watlow EZ-ZONE RME User Manual

Page 85: Saving and restoring user settings inputs outputs, Variable time base, Ten point linearization

Watlow EZ-ZONE

®

RME Module

•

82

•

Chapter 6 Features

Saving and Restoring User Settings

Recording setup and operations parameter settings

for future reference is very important. If you uninten-

tionally change these, you will need to program the

correct settings back into the controller to return the

equipment to operational condition.

After you program the controller and verify prop-

er operation, use User Settings Save [USr;S] (Setup

Page, Global Menu) to save the settings into either of

two files in a special section of memory.

Note:

Starting with firmware release 6, there is only one

user set.

If the settings in the controller are altered and you

want to return the controller to the saved values, use

User Settings Restore [USr;r] (Setup Page, Global

Menu) to recall the previously saved settings.

A digital input or the Function Key can also be

configured to restore parameters.

CAUTION:

If a Digital Input or Function Key is programmed for

User Setting Restore, the operator may select Fac-

tory Restore and the Digital Input or Function Key

may no longer be programmed for User Setting Re-

store.

Note:

Only perform the above procedure when you are sure

that all the correct settings are programmed into the

controller. Saving the settings overwrites any previ-

ously saved collection of settings. Be sure to document

all the controller settings.

Inputs

Ten Point Linearization

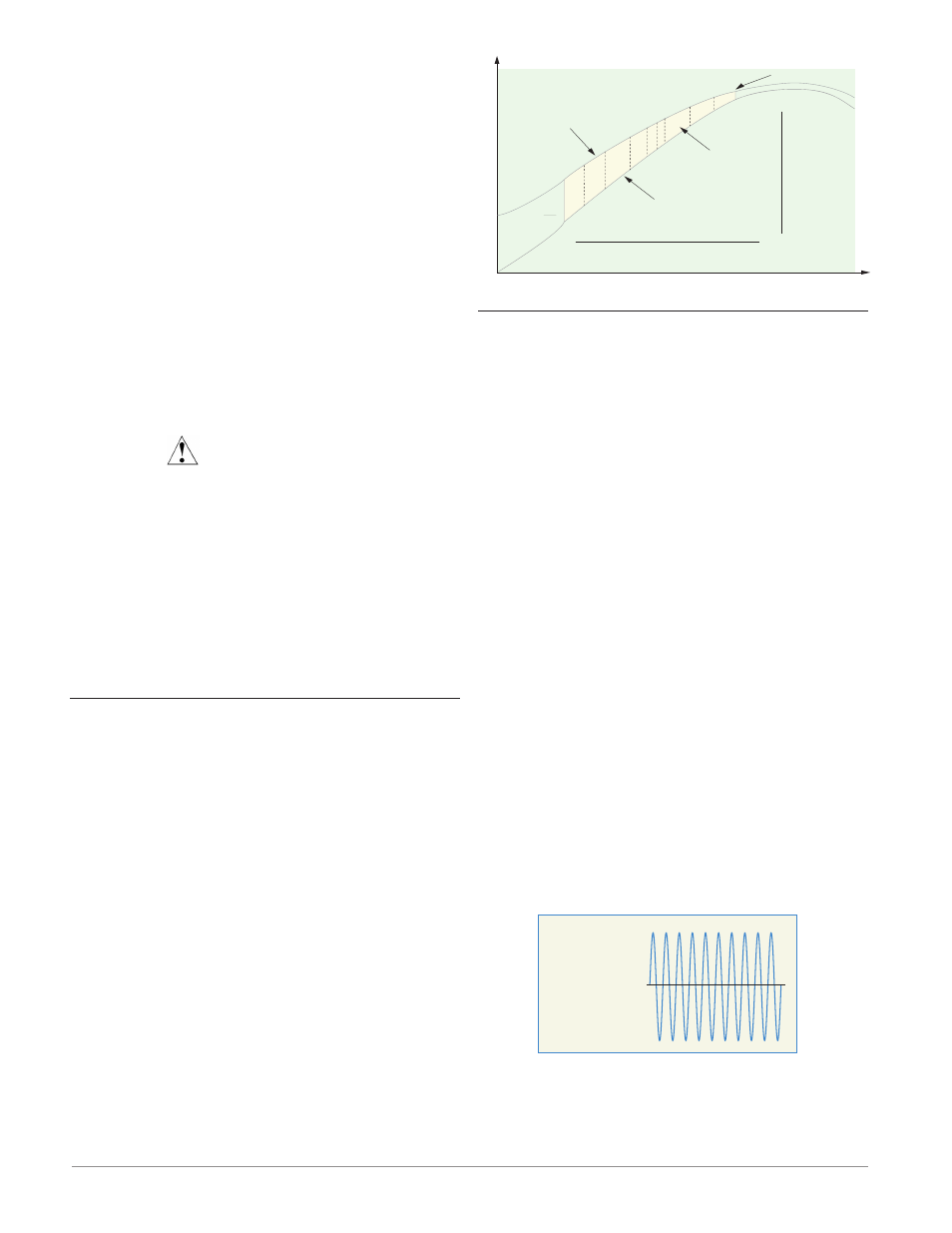

The linearization function allows a user to re-linear-

ize a value read from an analog source. The function

selections are Off, Interpolated and Stepped. When

set to Off the output will match the Source A value

plus offset. There are 10 data points used to compen-

sate for differences between the source value read

(input point) and the desired value (output point).

Multiple data points enable compensation for non-

linear differences between the sensor readings and

target process values over the thermal or process sys-

tem operating range. Sensor reading differences can

be caused by sensor placement, tolerances, an inaccu-

rate sensor or lead resistance.

The user specifies the unit of measurement and

then each data point by entering an input point value

and a corresponding output point value. Each data

point must be incrementally higher than the previous

point. The linearization function will interpolate data

points linearly in between specified data points.

2

3

4

5 6

7

8

9

Reading from Sensor

without Linearization

(Actual Value)

Input Point 1

Output Point 1

Input Point 10

Output Point 10

Offset Zone

Reading from Sensor

with Linearization

(Displayed Value)

No Offset

T

emperature

Time

Outputs

Variable Time Base

Variable time base is the preferred method for con-

trolling a resistive load, providing a very short time

base for longer heater life. Unlike phase-angle firing,

variable-time-base switching does not limit the cur-

rent and voltage applied to the heater.

With variable time base outputs, the PID algo-

rithm calculates an output between 0 and 100%, but

the output is distributed in groupings of three ac

line cycles. For each group of three ac line cycles, the

controller decides whether the power should be on or

off. There is no fixed cycle time since the decision is

made for each group of cycles. When used in conjunc-

tion with a zero cross (burst fire) device, such as a

solid-state power controller, switching is done only at

the zero cross of the ac line, which helps reduce elec-

trical noise (RFI).

Variable time base should be used with solid-state

power controllers, such as a solid-state relay (SSR)

or silicon controlled rectifier (SCR) power controller.

Do not use a variable time base output for control-

ling electromechanical relays, mercury displacement

relays, inductive loads or heaters with unusual resis-

tance characteristics.

The combination of variable time base output and

a solid-state relay can inexpensively approach the ef-

fect of analog, phase-angle fired control.

Select the AC Line Frequency [AC;LF] (Setup Page,

Global Menu), 50 or 60 Hz.

100 percent output

10 ON, 0 OFF