Alarms, Retransmitting a process value or set point, Compressor control – Watlow EZ-ZONE RME User Manual

Page 86: Motorized valve control

Watlow EZ-ZONE

®

RME Module

•

83

•

Chapter 6 Features

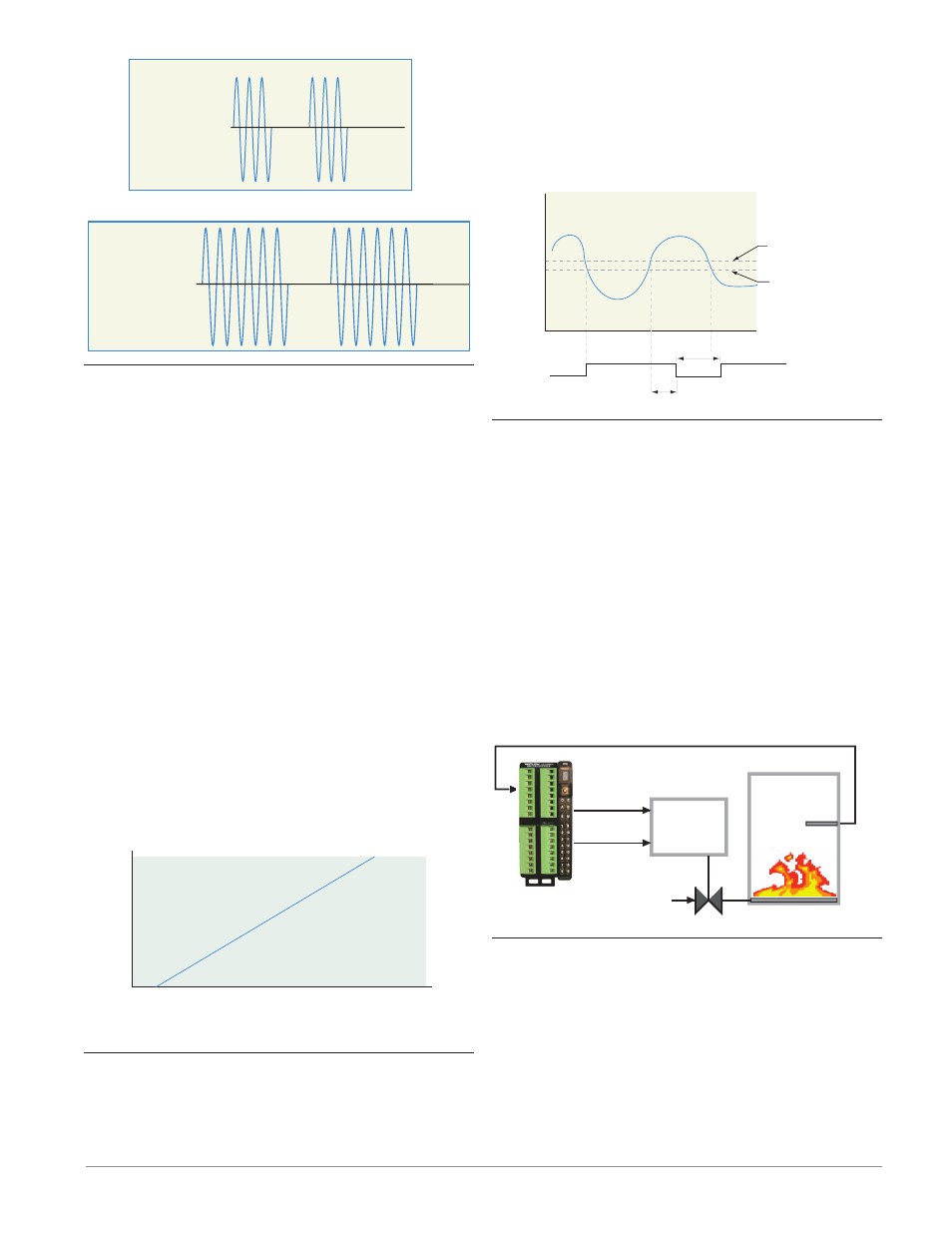

50 percent output

3 ON, 3 OFF

66 percent output

6 ON, 3 OFF

Retransmitting a Process Value or Set Point

The retransmit feature allows a process output to

provide an analog signal that represents the set point

or process value. The signal may serve as a remote

set point for another controller or as an input for a

chart recorder documenting system performance over

time.

In choosing the type of retransmit signal the op-

erator must take into account the input impedance

of the device to be retransmitted to and the required

signal type, either voltage or milliamperes.

Typically, applications might use the retransmit

option to record one of the variables with a chart re-

corder or to generate a set point for other controls in

a multi-zone application.

Outputs 1 to 3, 7 to 9, 13 to 15 and 19 to 21 can be

ordered as process outputs. Assign an analog source

to Output Function to accomplish retransmit of a

process or set point value.

Note:

The active set point is not retransmitted, only the

user requested closed loop set point which may not be

the closed loop set point in control. Retransmitting a

profiling closed loop set point is not allowed.

Retransmit

Retransmit Source

Output Scale

Range High

Range Low

Scale High

Scale Low

Compressor Control

The compressor control can save wear on a compres-

sor and prevent it from locking up from short cycling.

A bypass valve operated by a control output regu-

lates how the process is cooled, while another output

switches the compressor on and off. The compressor

will not turn on until the output power exceeds the

Compressor On % Power for a time longer than the

Compressor On Delay. The compressor will not turn

off until the output power exceeds the Compressor

Off % Power for a time longer than the Compressor

Off Delay.

0% Compressor

On Power

Off

On

100%

2%

0%

-100%

Compressor On Delay = 45 Seconds

Compressor Off Delay = 20 Seconds

2% Compressor

Off Power

Time In Seconds

% Power

Heat

Cool

Compressor

Motorized Valve Control

A motorized valve is used is to regulate the flow of

fluid which in turn impacts the loop process value. A

valve is opened or closed by closing contacts to drive

the value in the intended direction. This feature is

configured by selecting Motorized Valve as the func-

tion in the Setup Page, Special Output Function

menu. Source Function A is selected for either Heat

or Cool Power then entering the Valve Travel Time

and Deadband.

Lastly, program the outputs which will open and

close the valve. The algorithm will calculate Dead

Time which is the minimum on time that the valve

will travel once it is turned on in either the closed or

open direction. Dead Time = Valve Dead Band / 100

* Valve Travel Time.

Output 1 = Close

Temperature

Sensor

Gas Furnace

Output 2 = Open

Gas Flow

Valve

Actuator

®

Alarms

Alarms are activated when the output level, process

value or temperature leaves a defined range. A user

can configure how and when an alarm is triggered,

what action it takes and whether it turns off auto-

matically when the alarm condition is over.

Configure alarm outputs in the Setup Page before

setting alarm set points.

Alarms do not have to be assigned to an output.

Alarms can be monitored and controlled through the

front panel or by using software.