Calibration valves options, Ambient zero/pressurized span valve – Teledyne GFC-7000T - Trace CO2 Analyzer - manual User Manual

Page 72

FAQ

Model GFC7000TA Carbon Dioxide Analyzer

Teledyne Analytical Instruments

54

5.4. Calibration Valves Options

There are four available options involving Zero/span valves. From an operational and software

standpoint, all of the options are the same, only the source of the span and zero gases are different.

5.4.1. Ambient Zero/Pressurized Span Valve

This option requires that both zero air and span gas be supplied from external sources. It is specifically

designed for applications where span gas will be supplied from a pressurized bottle of calibrated CO

2

gas.

A critical flow control orifice, internal to the instrument ensures that the proper flow rate is maintained. An

internal vent line, isolated by a shutoff valve ensures that the gas pressure of the span gas is reduced to

ambient atmospheric pressure. Normally zero air would be supplied from zero air modules such as a

Teledyne Instruments Model 701.

In order to ensure that span gas does not migrate backwards through the vent line and alter the

concentration of the span gas, a gas line not less than 2 meters in length should be attached to the vent

span outlet on the rear panel of the analyzer. To prevent the buildup of back pressure, this vent line

should not be greater than 10 meters in length.

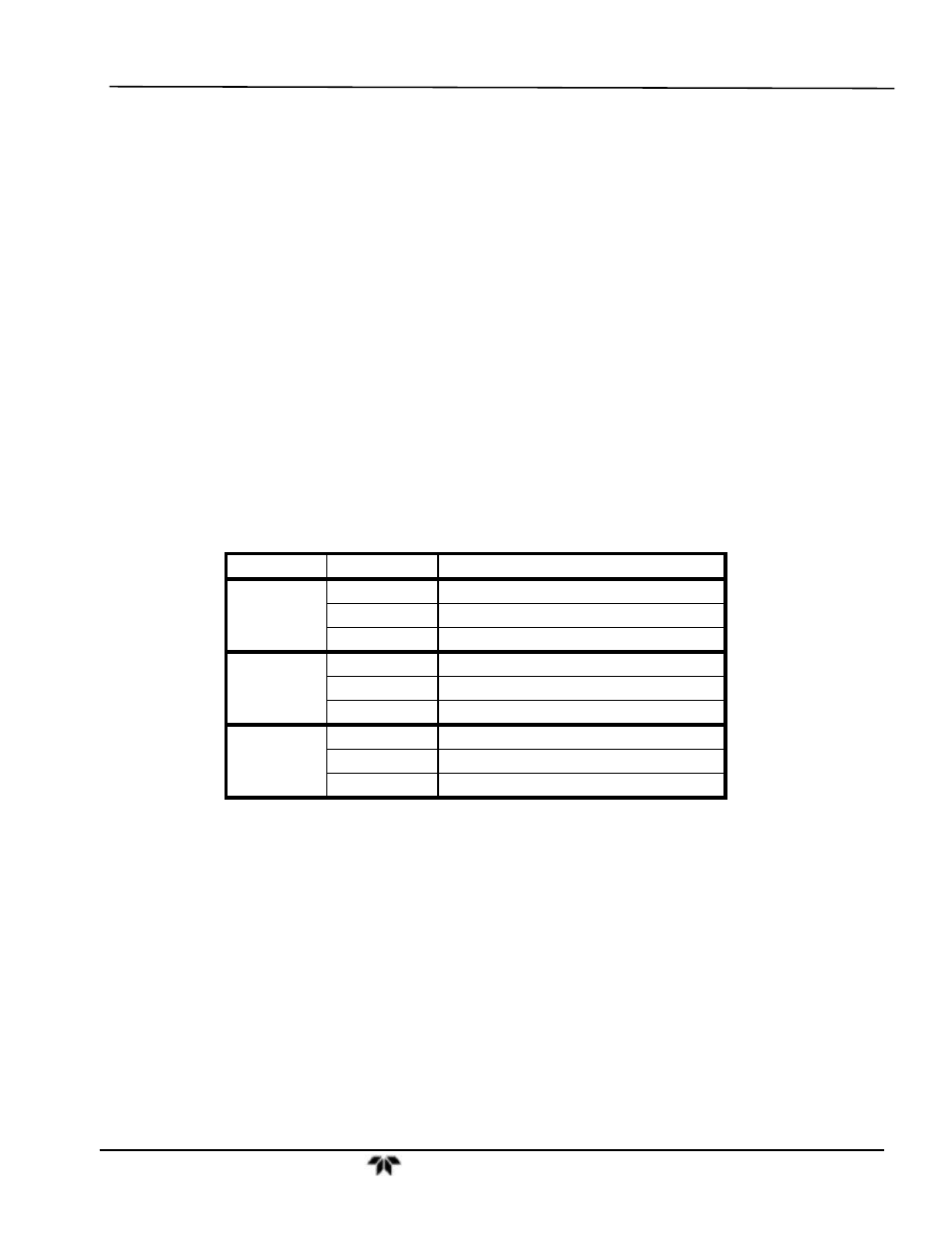

The following table describes the state of each valve during the analyzer’s various operational modes.

Table 5-1: Ambient Zero/Pressurized Span Valve Operating States

MODE VALVE

CONDITION

SAMPLE

(Normal State)

Sample/Cal

Open to SAMPLE inlet

Zero/Span

Open to IZS inlet

Shutoff Valve

Closed

ZERO CAL

Sample/Cal

Open to ZERO/SPAN valve

Zero/Span

Open to IZS inlet

Shutoff Valve

Closed

SPAN CAL

Sample/Cal

Open to ZERO/SPAN valve

Zero/Span

Open to SHUTOFF valve

Shutoff Valve

Open to PRESSURE SPAN Inlet

The minimum span gas flow rate required for this option is 800 cm

3

/min.

The state of the zero/span valves can also be controlled:

Manually from the analyzer’s front panel by using the SIGNAL I/O controls located under the DIAG

Menu (Section 6.13.2),

By activating the instrument’s AutoCal feature (Section 7.6),

Remotely by using the external digital control inputs (Section 6.15.1.2 and Section 7.5.2), or;

Remotely through the RS-232/485 serial I/O ports (see Appendix A-6 for the appropriate commands).