Using the diagnostic signal i/o function – Teledyne GFC-7000T - Trace CO2 Analyzer - manual User Manual

Page 241

Troubleshooting

Model GFC7000TA Carbon Dioxide Analyzer

Teledyne Analytical Instruments

223

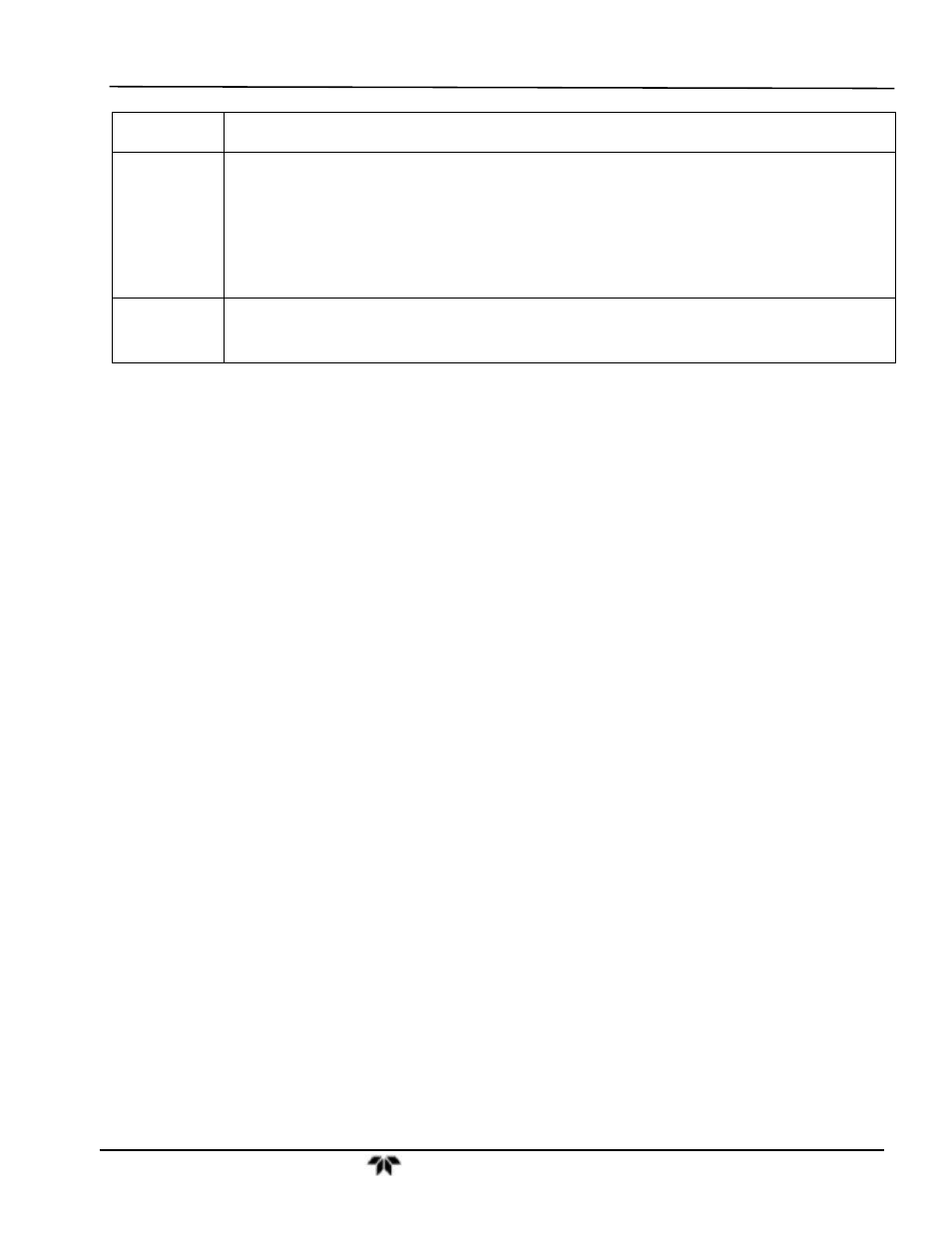

TEST

FUNCTIONS

INDICATED FAILURE(S)

SLOPE

Values outside range indicate

Contamination of the zero air or span gas supply

Instrument is miss-calibrated

Blocked gas flow

Contaminated or leaking GFC wheel (either chamber)

Faulty IR photo-detector

Faulty sample faulty IR photo-detector pressure sensor (P1) or circuitry

Invalid M/R ratio (see above)

Bad/incorrect span gas concentration due.

OFFSET

Values outside range indicate

Contamination of the zero air supply

Contaminated or leaking GFC wheel (either chamber)

Faulty IR photo-detector

10.1.3. Using the Diagnostic Signal I/O Function

The Signal I/O parameters found under the DIAG Menu (See Section 6.9.2 and Appendix A) combined

with a thorough understanding of the instrument’s Theory of Operation (found in Section 10) are useful for

troubleshooting in three ways:

The technician can view the raw, unprocessed signal level of the analyzer’s critical inputs and

outputs.

All of the components and functions that are normally under algorithmic control of the CPU can be

manually exercised.

The technician can directly control the signal level of the Analog and Digital Output signals.

This allows the technician to systematically observe the effect of directly controlling these signals on the

operation of the analyzer. Below in Figure 11-2 is an example of how to use the signal I/O menu to view

the raw voltage of an input signal or to control the state of an output voltage or control signal. The

specific parameter will vary depending on the situation.