Sample gas flow, Flow rate control, Critical flow orifice – Teledyne GFC-7000T - Trace CO2 Analyzer - manual User Manual

Page 212

Theory of Operation

Model GFC7000TA Carbon Dioxide Analyzer

Teledyne Analytical Instruments

194

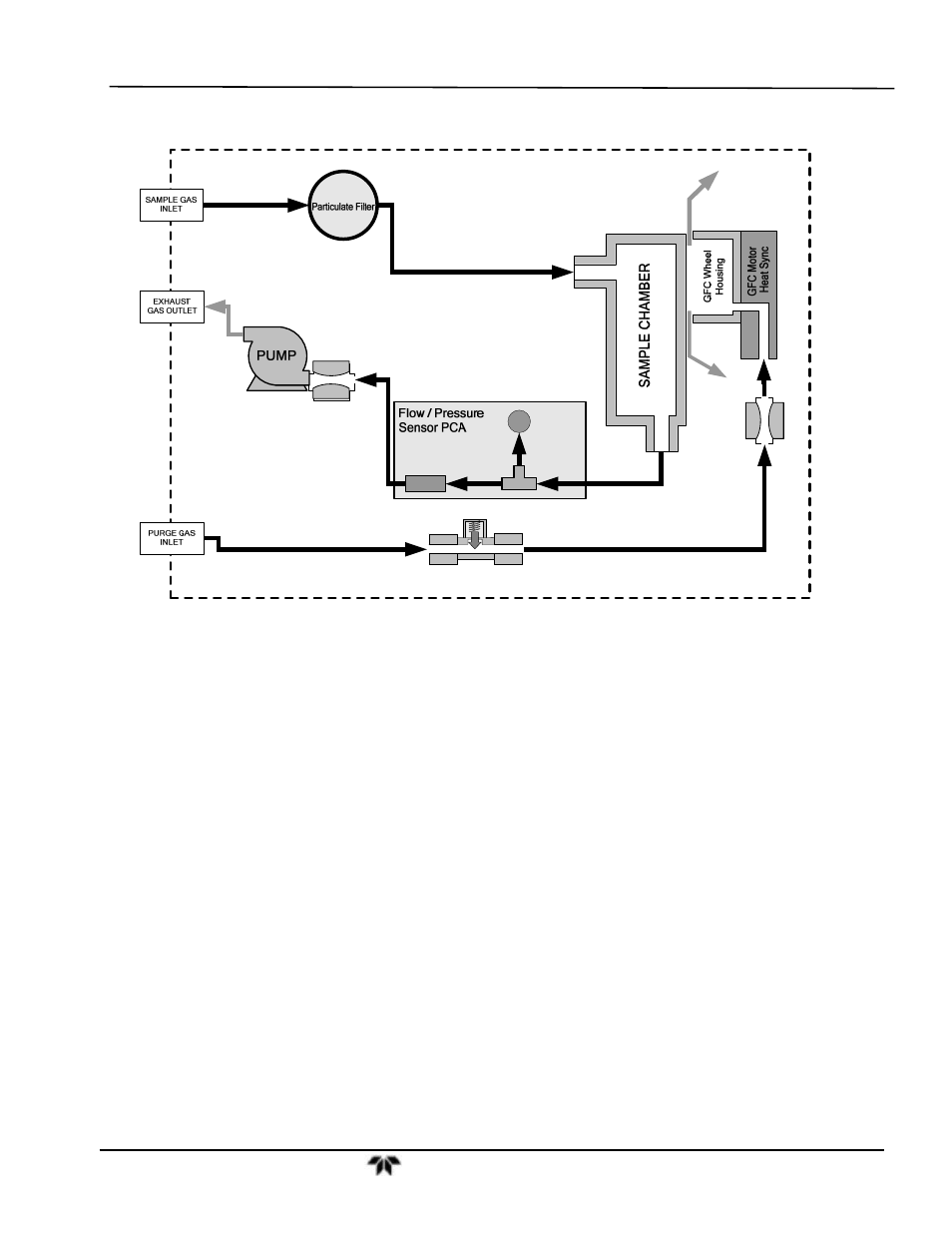

9.2.1. Sample Gas Flow

SAMPLE

PRESSURE

SENSOR

CO

2

FLOW

SENSOR

Sample Gas

Flow Control

Purge Gas

Flow Control

Purge Gas

Pressure Control

Figure 9-7:

Internal Pneumatic Flow – Basic Configuration

9.2.2. Flow Rate Control

To maintain a constant flow rate of the sample gas through the instrument, the Model GFC 7000TA uses

special flow control assemblies located in the purge gas line at the entrance to the GFC wheel housing

and in the exhaust gas line just before the pump (see Figure 10-7). These assemblies consists of:

A critical flow orifice.

Two o-rings: Located just before and after the critical flow orifice, the o-rings seal the gap between

the walls of assembly housing and the critical flow orifice.

A spring: Applies mechanical force needed to form the seal between the o-rings, the critical flow

orifice and the assembly housing.

9.2.2.1. Critical Flow Orifice

The most important component of this flow control assembly is the critical flow orifice.

Critical flow orifices are a remarkably simple way to regulate stable gas flow rates. They operate without

moving parts by taking advantage of the laws of fluid dynamics. By restricting the flow of gas though the

orifice, a pressure differential is created. This pressure differential combined with the action of the

analyzer’s pump draws the gas through the orifice.

As the pressure on the downstream side of the orifice (the pump side) continues to drop, the speed that

the gas flows though the orifice continues to rise. Once the ratio of upstream pressure to downstream