0 mounting (cont’d), 3 curb cap base and mounting (cont’d), Roof curb – Reznor ZQYRA Unit Installation Manual User Manual

Page 8: 2 mounting on a roof curb (cont’d)

Form I-ZQYRA P/N 260414R5, Page 8

5.0 Mounting

(cont’d)

5.3 Curb Cap Base

and Mounting

(cont’d)

5.3.2 Mounting on a

Roof Curb (cont’d)

Roofing Felts

(by others)

Cant Strip

(by installer)

Counter Flashing

(by installer)

MUST be sealed between

curb cap and roof curb.

2 x 6

Wood

Nailer

Insulation

Weld, bolt, or lag screw curb to deck structure.

Roof Curb

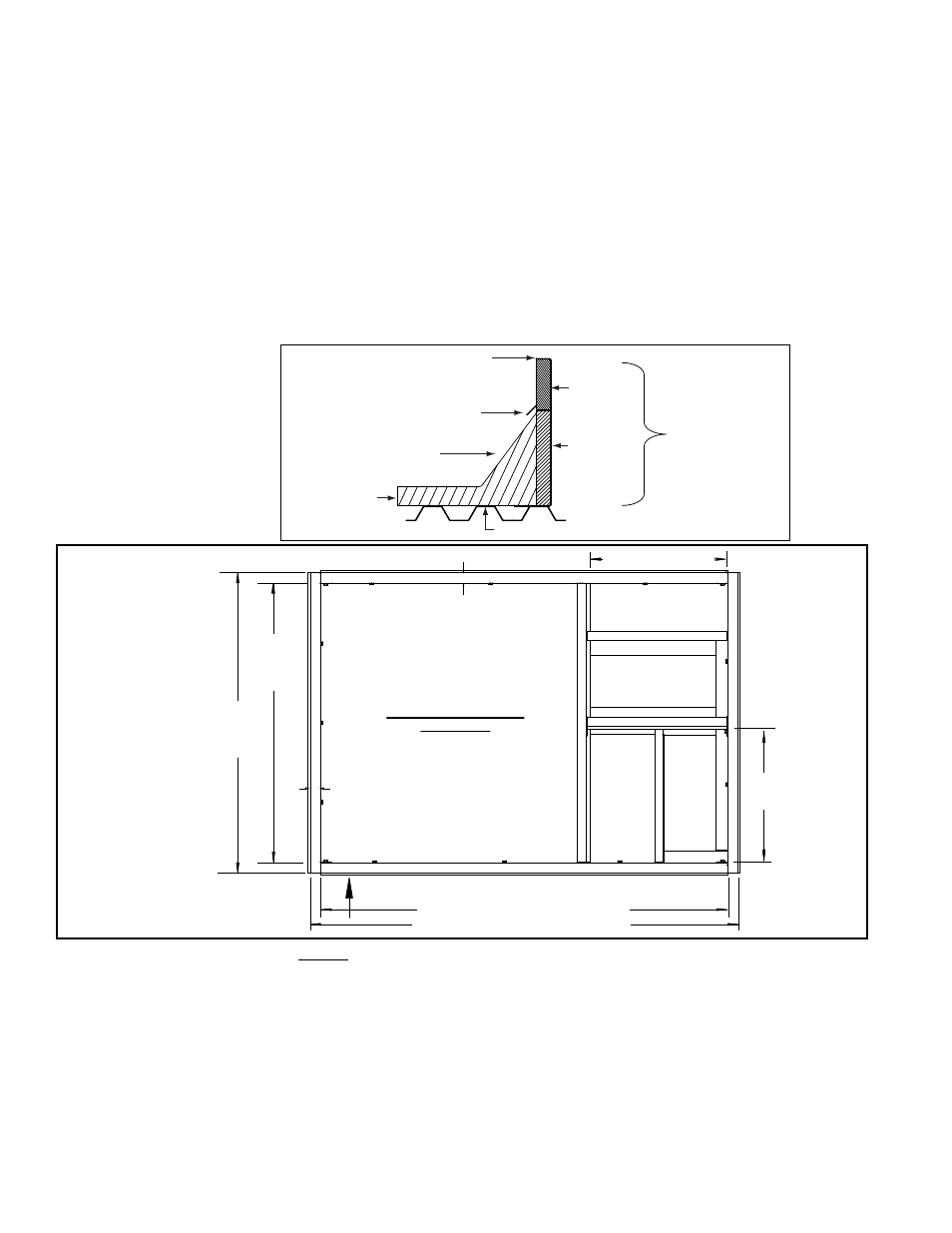

FIGURE 7 - Cross-

section of Roof Curb

showing Construction

Detail

7.

Before lifting and placing the unit on the curb, check the following:

□

The curb is designed for ductwork to be installed from the top BEFORE the unit

is in place. Slide the ductwork down into the discharge and return air openings.

See dimensions in

FIGURE 8. Ductwork should be sized slightly smaller with a

minimum 3/4" duct flange that will attach to all sides of the duct connection in the

curb. See Paragraph 6.2 for connecting ductwork.

□

Apply 1/4" x 1-1/4" foam sealant tape to both the top surface of the curb rails and

the top surface of the duct connection supports, being sure to make good butt

joints at all corners. The sealant tape must be applied to the rails to prevent water

leakage into the curb area due to blown rain and capillary action.

□

The unit has field convertible (either vertical or horizontal) supply and return air

opening locations. Depending on whether the ductwork is vertical or horizontal,

44-1/8”

(1121mm)

- inside

of curb

47-7/16”

(1205mm)

- outside

of rails

Rail Width

1-21/32”

(42mm)

Rail Width

1-21/32”

(42mm)

Outside Air Inlet Location

(on side of unit)

TOP VIEW of Assembled

ROOF CURB

Exhaust Air

Outlet Location

(on side of unit)

Supply Air

Opening

18-7/32” x 8-1

1/64”

(463mm x 2

08mm)

64-5/32” (1629mm) - inside of curb

67-15/32” (1713mm) - outside of rails

21-1/2”

(546mm)

Return Air Opening

19-51/64” x 8-11/64”

(503mm x 208mm)

22-1/4” (565mm)

Horizontal Return

Air Opening

Location on

Side of Unit

Supply

Air Opening

Location on

Side of Unit

FIGURE 8 -

Option CJ3C

Roof Curb and

Duct Opening

Dimensions

Slide return

air and supply

ductwork down

from the top

and attach to

duct flanges.

Apply sealant

tape to top of all

curb rails.

Instructions and Requirements for Assembling and Installing Roof Curb

Option CJ3C (cont’d)

3. Identify the duct supports that create the integral supply and return air ductwork.

NOTE: If the system is not using the vertical duct openings, the duct support parts

are not required but may be installed.

Position the duct support parts as shown in

FIGURE 6 and attach. Use 1-1/4” lag

screws with lockwashers when attaching supports to the top portion of the curb

rails with the wood nailer. Use sheetmetal screws in all other locations.

4. Check the roof curb for squareness. The curb must be adjusted so that the

diagonal measurements are equal within a tolerance of ±1/8" (3mm).

5. Level the roof curb. To ensure a good weatherproof seal between the cabinet curb

cap and the roof curb, the curb must be leveled in both directions with no twist end

to end. Shim as required and secure curb to the roof deck before installing flashing

(See Curb Detail in

FIGURE 7).

6. Install field-supplied flashing.