Roof curb, option cj3c – Reznor ZQYRA Unit Installation Manual User Manual

Page 7

Form I-ZQYRA P/N 260414R5, Page 7

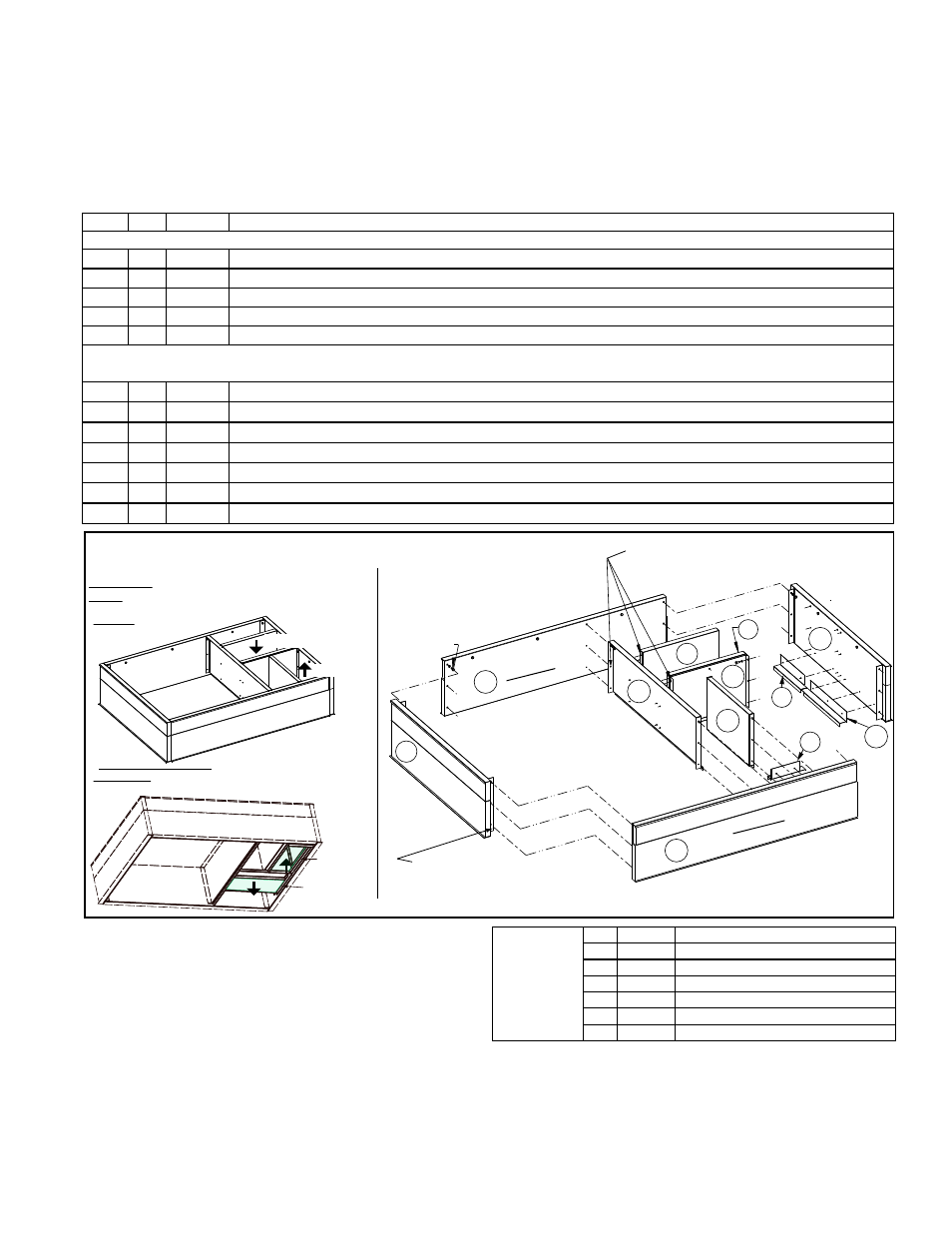

Roof Curb,

Option CJ3C

Roof curb Option CJ3C, is shipped separately for field installation. The roof curb

designed for this system includes integral duct connections for supply air and return air

making it very important to know the orientation of the unit when installing the

curb. See the illustrations in FIGURE 6 and the component list below. See dimensions

in

FIGURE 8, page 8 and orientation in FIGURE 9, page 9.

The roof curb is designed for ductwork to be installed from the top prior to setting the

unit. If ductwork is installed after the unit, field-fabricated custom connections will be

required as the unit does not have duct flanges.

FIGURE 6 - Layout of Roof Curb Components listed above

Item Qty

P/N

Description

Roof Curb Rail and Cross Support Parts, Items A, B, C, D, and E are ALWAYS used:

A

1

260215 Roof Curb Front Side

B

1

260216 Roof Curb Right End

C

1

260217 Roof Curb Left End

D

1

260218 Roof Curb Rear Side

E

1

259636 Roof Curb Center Support

Vertical Duct Support Parts (Items F-M) are required if the application has vertical supply and return air.

Installation of these parts is optional if installing a unit using the horizontal supply and return air openings.

F

1

259637 Roof Curb Cross Support (return air)

G

1

259638 Roof Curb Cross Support (discharge air)

H

1

259639 Roof Curb Cross Support (return air)

J

1

259640 Roof Curb Center Support (discharge air)

K

1

259641 Duct Angle Support (discharge air right end)

L

1

259642 Duct Angle Support (discharge air front side)

M

1

259643 Duct Angle Support (return air right end)

1

2

3

4

5

6

7

8

9

10

11

(Right End)

(Center

Support)

(Left End)

Top View (showing supply

and return airflow)

(Front Side)

(Rear Side)

L

A

J

E

G

C

F

M

B

D

H

K

Use 3/4” Cap Screw, P/N 16247,

with Lockwasher, P/N 1333, and Nut,

P/N 1035, in bottom two holes in each corner.

Use 1-1/4” Lag Screw, P/N 16243,

with Lockwasher, P/N 1333, in all

attachmentsmade into the wood

nailer around the top

of the curb.

Use sheetmetal screws, P/N 11813, for

attaching duct support parts to each

other and to the insulated portion of

the curb rails.

Assembled

Views

Slide vertical ductwork down from the top

and attach to duct flanges at bottom of curb.

See dimensions on page 8.

Bottom View (from inside the building showing flanges for

ductwork on the openings on the bottom of the curb)

Return Air

Duct Flange

Supply Air

Duct Flange

Return Air

Supply Air

Components in Option

CJ3C, Pkg P/N 260418

Instructions and

Requirements for

Assembling and

Installing Roof Curb

Option CJ3C

The option package

includes the following

hardware:

Roof Curb

Hardware

Bag

includes:

Qty

P/N

Description

10 16243 Hex Hd Lag Bolt 5/16 X 1-1/4” lg

18

1333 Lockwasher 5/16 In.

8

16247 Cap Screw 5/16 X 3/4” lg

8

1035 Hex Nuts

31

11813 S/M Screw #10-16x1/2 Ab Stalgd

66302 Roll of Sealant Tape, 1/4” x 1-1/4”

1. Verify that the roof curb parts match those listed in the package component table

and the hardware bag component table above.

Verify that the location has adequate support for the weight (Paragraph 5.1).

2. Position the roof curb end and side assemblies as shown in

FIGURE 6. Fasten

each corner using lag screws with lockwashers in the top holes and cap screws

with lockwashers and nuts in each of the other holes. Install the center support.

Before continuing to Step 3, verify that the airflow orientation is correct.