Reznor ZQYRA Unit Installation Manual User Manual

Page 63

Form I-ZQYRA P/N 260414R5, Page 63

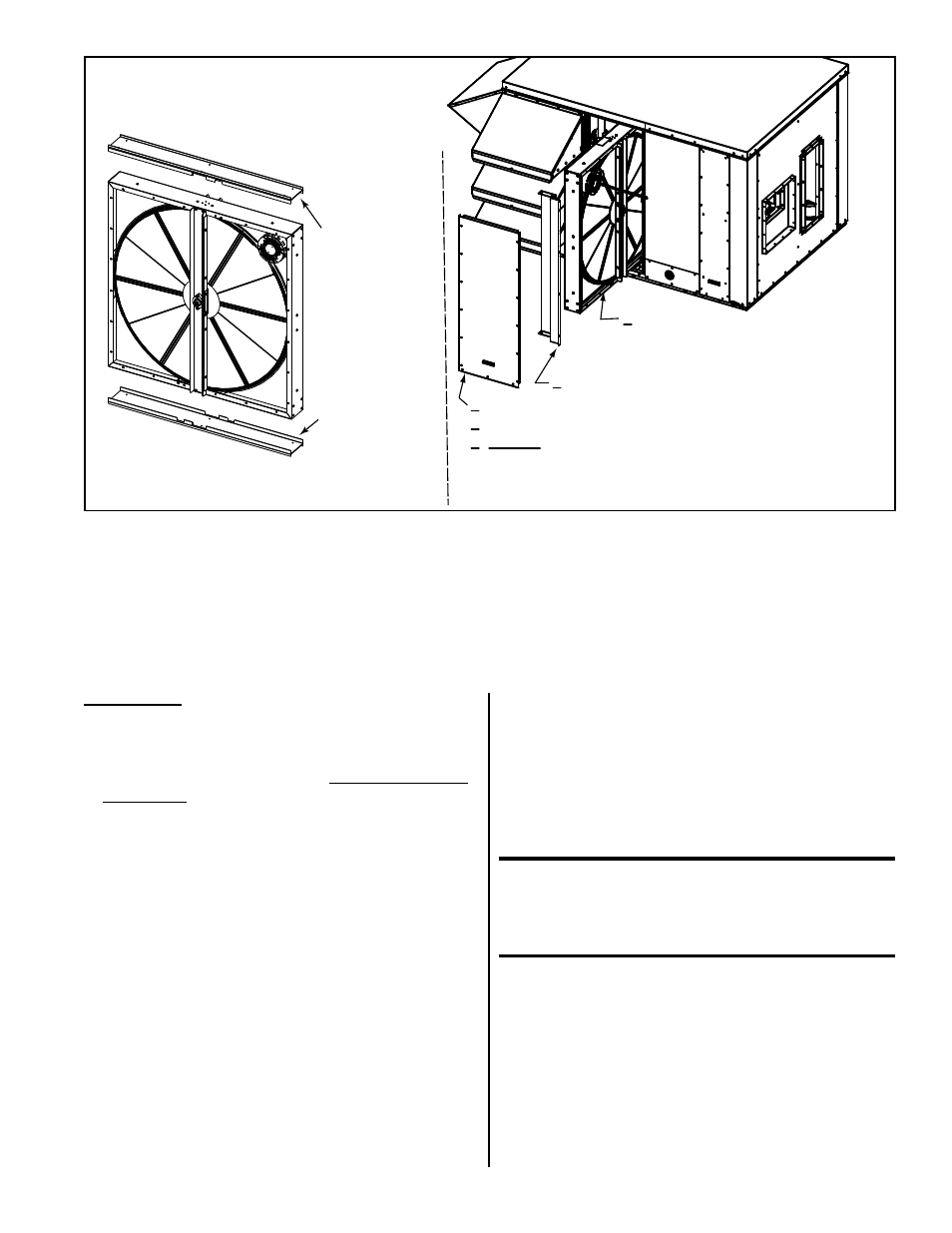

Top and bottom

wheel supports

will slide out

with the wheel.

When returning

the wheel to the

cabinet, match

the notches with

the bearing

supports.

1) Turn the power off to the unit.

2) Remove the wheel access panel.

3) Size 12 - On the post to the right of the wheel, remove

the screws holding the outside air sensor. Move the

sensor so that it does not interfere with wheel removal.

wheel removal.

4) Remove blockoff panel.

5) Disconnect the plug in the

wheel motor wiring and slide the

entire cassette out of the cabinet.

FIGURE 33 - Removing Energy Recovery

Wheel Cassette

According to the manufacturer, a wheel operating in a “clean” environment may not require annual cleaning, but a wheel

in a “contaminated” environment may require multiple cleanings a year to maintain airflow and recovery. The segmented

design of the wheel not only provides for easier cleaning but also allows for replacement of individual dirty segments.

Replacement part numbers are available from your distributor or at www.RezSpec.com.

Removing, Cleaning,

and Replacing Wheel

Segments

The segments are the “heat exchangers” of the energy recovery wheel. Segments

must be handled with care and should never be dropped. Segments may require

“slight” persuasion during installation and removal but NEVER be forced or banged

with a hammer or similar tool.

Instructions:

1. T

urn off power to the unit and follow steps in

FIGURE 33 to slide the wheel cassette out of the

cabinet.

2. Remove the Wheel Segments (from the pulley side

of the wheel)

a) Rotate the wheel to position the first segment to be

removed at the top. On both sides of the segment,

unlock and open the two retaining straps.

b) Using hand pressure only and supporting the

segment, from the motor side push the wheel

segment. On the pulley side, lift the segment out of

the spokes. Lay, do not drop, the segment on a flat

surface

c) Rotate the wheel so that the segment on the

opposite side is on the top. Repeat the procedure

and remove the segment. Continue the procedure

of keeping the balanced open and filled segments

opposite each other and remove all of the

segments.

3. Clean the Wheel Segments

a) Gently brush off any loose dirt and dust.

b) To wash the segments, use a non-acid based

(evaporator) coil cleaner or alkaline detergent

solution. Non-acid based coil cleaner concentrate

in a 5% solution is recommended by the

manufacturer. DO NOT use acid based cleaners,

aromatic solvents, temperatures in excess of 170°F,

or steam as these may cause damage to the wheel.

DO NOT use a pressure washer.

Soak the segments in the cleaning solution until

grease and tar deposits are loosened. An overnight

soak may be required to adequately loosen heavy

deposits of oil based contaminants.

CAUTION: DO NOT use acid based cleaner,

aromatic solvent, steam, temperatures in

excess of 170°F, or a pressure washer, as

damage to the wheel may occur.

c) Rinse the dirty solution from each segment until

the water runs clear.

NOTE: Some staining of

the desiccant may remain and is not harmful to

performance. Allow excess water to drain from the

segments before reinstalling them in the wheel.

(

NOTE: A small amount of water will dry out in the

airflow.)

4. Replace or Re-install Clean Wheel Segments (from

pulley side of wheel)

a) Remove any dirt or dust from the wheel and

cassette and the slide-in area of the cabinet.