Model zqyra startup form, Appendix (cont’d), Startup form – Reznor ZQYRA Unit Installation Manual User Manual

Page 71

Form I-ZQYRA P/N 260414R5, Page 71

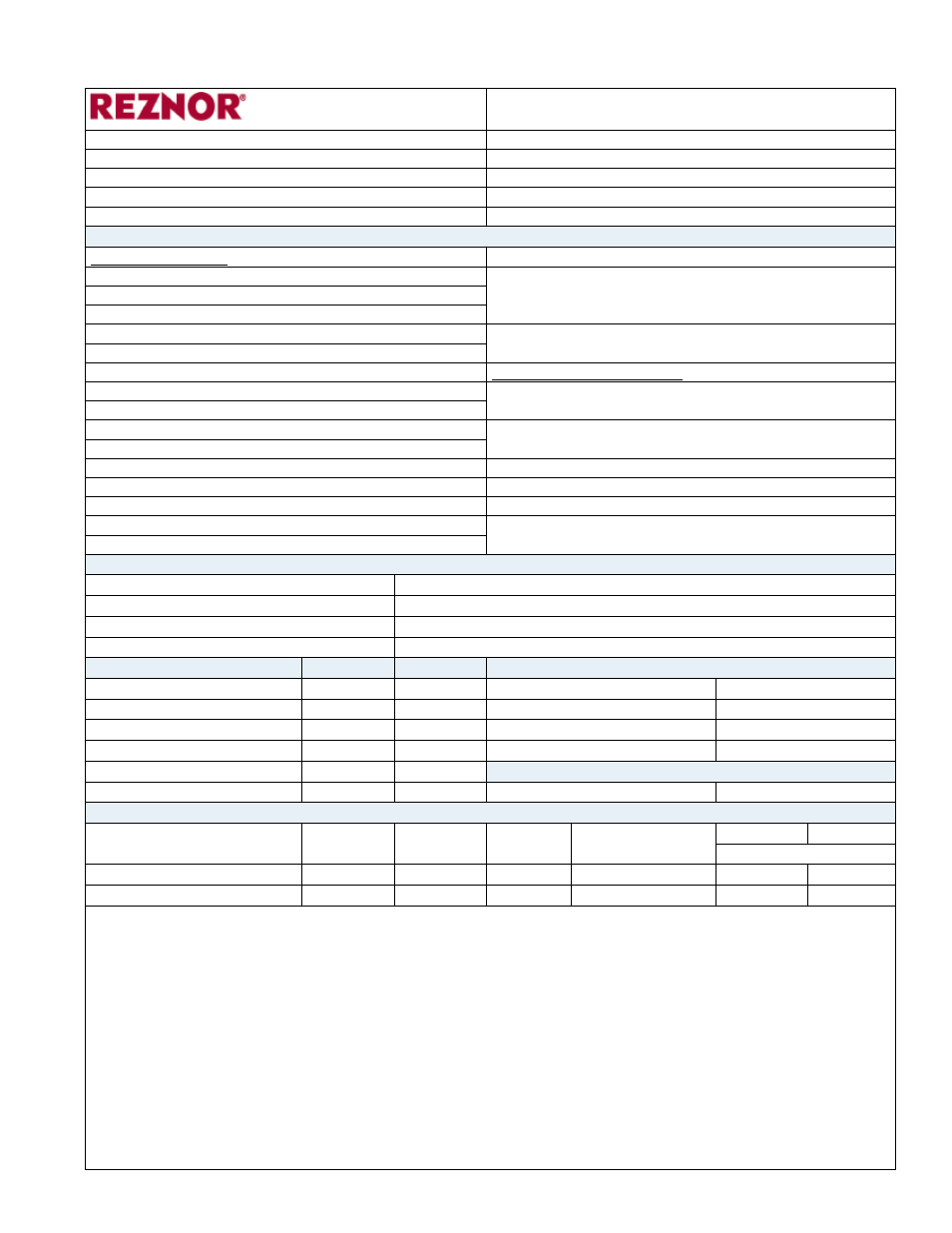

Startup Form

Model ZQYRA Startup Form

Job Name:

Contractor Contact:

Street Address

Contractor Phone:

City, State, Zip

Unit Size:

Date:

Unit Serial #

Contractor:

Tag:

Startup Check List (Paragraph refers to information location in Form I-ZQYRA, Installation Manual.)

Preparation Checks:

Check inlet and exhaust dampers (optional).

Inspect unit for damage (Paragraph 3.1).

Check wheel for alignment and free rotation. Also,

check for cleanliness, position of the seals, and belt

tension (Maintenance Paragraph 10.2.4).

Unit clearances as required (Paragraph 4.1).

Curb level and installed correctly (Paragraph 5.3.1).

Two unused duct connection openings sealed.

Verify crankcase heater has been energized for 24 hrs

before startup (Paragraph 7.4.3)

Exhaust air hood installed (Paragraph 6.2.2).

Inlet air hood with filter installed (Paragraph 6.2.3).

Startup Procedures/Checks:

Condensate trap installed (Paragraph 6.4).

Check compressor rotation (NOT fan rotation) to verify

correct 3-phase wiring connection. (Paragraph 7.1)

All electrical entrances sealed.

Electrical disconnect switch installed (Paragraph 7.2). If using an optional remote display, reset address

(Paragraph 7.5)

All electrical terminals tightened.

Voltage imbalance checked (Paragraph 7.1).

Run unit in test mode (Paragraph 9.2)

230V conversion wiring (if required) (Paragraph 7.2).

Set fan speeds (Paragraph 9.3)

Manual high pressure switch reset (Paragraph 7.4).

Check subcooling and superheat (Paragraph 10.2.5)

External control wiring verified (Paragraphs 7.2 & 7.5). If equipped with a dirty filter alarm, set dirty filter

pressure switch. (Paragraph 8.8)

Verify inlet and return air filters in place.

Functional Testing - Record the following:

Outside Air db/wb

Return Air db/wb

Unit Voltage (rating plate)

Unit MOP/MCA (rating plate)

Air Management Systems

Supply

Exhaust

Energy Recovery Wheel

Motor Speed Control Setting

Motor Amperage

External Duct Static Pressure

Wheel RPM (Paragraph 10.2.4)

Unit CFM (Paragraph 9.3)

Discharge Air Temperature

Motor Amps L1

Motor Amps L2

Optional Electric Preheat

Motor Amps L3

Electric Heat Amps

Heat Pump System - Test for one hour maximum run time. DO NOT test heating mode above 80°F (24°C).

Compressor

L1

L2

L3

Compressor %

Subcooling Superheat

(Paragraph 10.2.5)

Heating Mode

Ramp up to 30%

Cooling Mode

Ramp up to 100%

Comments/Notes

APPENDIX (cont’d)