3 troubleshooting, Danger, 1 general troubleshooting – Reznor ZQYRA Unit Installation Manual User Manual

Page 67

Form I-ZQYRA P/N 260414R5, Page 67

DANGER

This unit contains R-410A high pressure refrigerant. Hazards exist that could result in personal

injury or death. Installation, maintenance, and service should only be performed by an HVAC

technician qualified in R-410A refrigerant and using proper tools and equipment. Due to much

higher pressure of R-410A refrigerant, DO NOT USE service equipment or tools designed for R22

refrigerant.

IMPORTANT: Do not release refrigerant to the atmosphere! If required service procedures include the adding

or removing of refrigerant, the service technician must comply with all federal, state and local laws. The proce-

dures discussed in this manual should only be performed by a qualified HVAC technician.

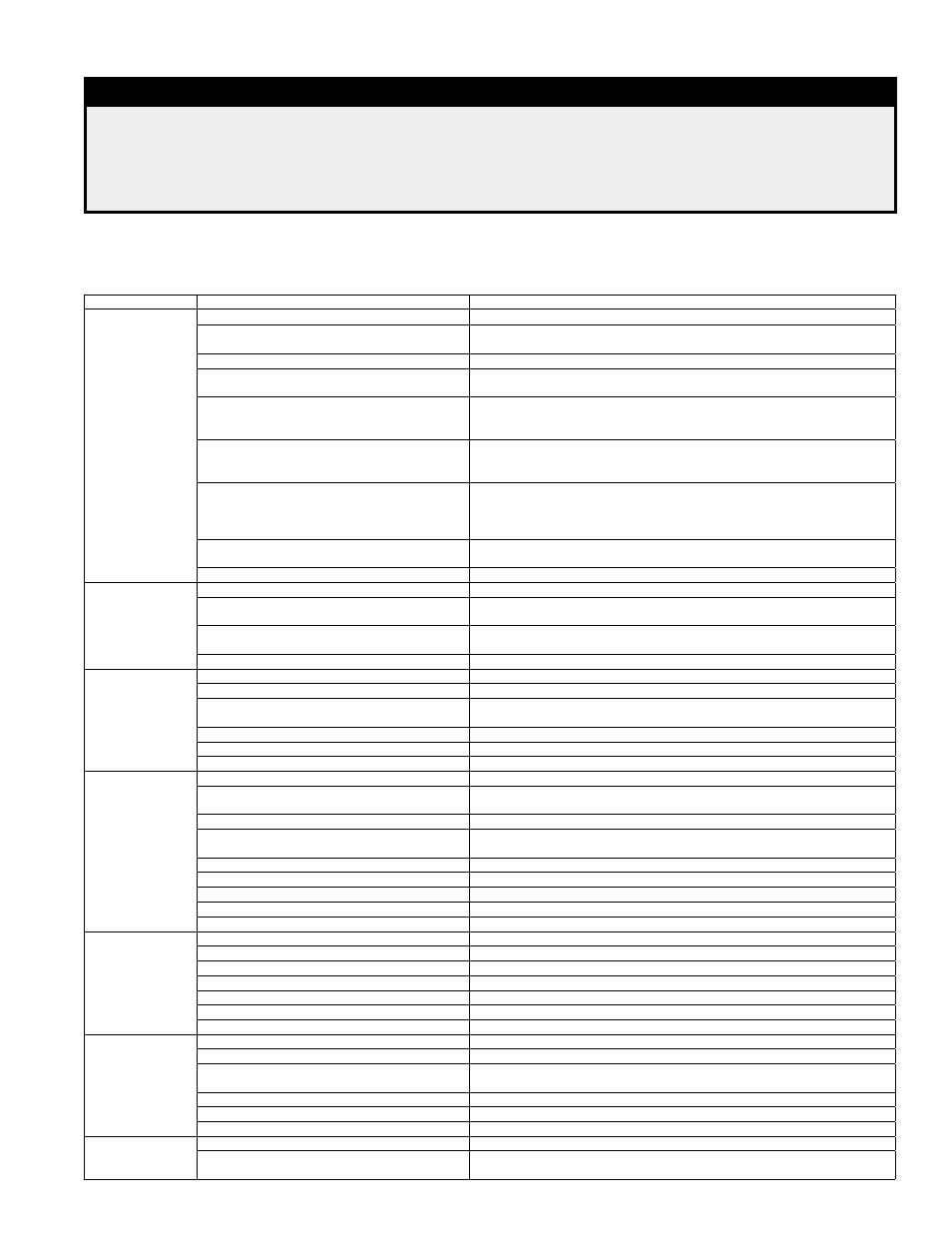

10.3 Troubleshooting

10.3.1 General Troubleshooting

Symptom

Possible Cause

Corrective Action

"Compressor will

not run or does not

try to start"

Open disconnect switch or circuit breaker.

Close switch and / or breaker.

Compressor contactor not closing.

Check voltage to contactor coil, transformer, relay, system. Replace parts as

necessary.

Blown fuse or tripped breaker

Check for reason and repair. Replace fuse after correcting problem.

Low line voltage.

Check line voltage. If more than 10% from compressor marking, correcting

is necessary.

Compressor motor protector open.

Motor thermal protector automatically resets. Allow time (2 hrs.) for

compressor to cool down so protector will reset. Restart and check for

reason overheat occurred

Compressor defective.

Check motor for open circuit, short circuit, grounded windings or burn

out. Compressor may be seized; check refrigerant. If necessary, replace

compressor.

High or low pressure switch open or defective.

If (high pressure), re-set switch. (Switch opens at 600 psi and will not reset

above 420 psi for R-410A.) If HP switch does not reset and everything

else is OK, replace switch. If auto reset (low pressure) does not reset and

everything else is OK, replace switch.

Open room thermostat or control (no cooling

required).

Check room temperature. If temperature is proper, wait for thermostat to

close.

Loose wiring.

Check all wire terminals and tighten as necessary.

"Compressor starts

but cuts out on

low pressure. Low

pressure switch

activates at 50 psig

for R-410A."

Low refrigerant charge.

Check refrigerant pressures. If refrigerant pressure is low, check for leaks.

Airflow restricted.

Check for dirty evaporator coil, dirty filters, dampers closed, iced evaporator

coil, improper belt, check motor amps, check duct design.

Restriction in refrigerant line.

Check refrigerant pressure, check and adjust thermal expansion valve. If not

functioning properly, check for pressure drop across the filter drier.

Defective low pressure switch.

Replace.

"Compressor

starts but cuts out

on high pressure

switch. High

pressure activates

at 600 psig for

R-410A."

Refrigerant overcharge.

Check pressures, charge by subcooling.

In heating mode low air flow over air coil.

Change filter or clean air coil.

Air or non-condensables in system.

Check high side equalized pressure reading with equivalent outdoor

temperature.

Defective high pressure switch.

Replace.

Restriction in discharge or liquid line.

Check refrigerant line pressures, check thermal expansion valves.

Reheat valve and bypass valve not opening.

Check valves or valve circuit board.

"Compressor cuts

out on thermal

overload."

Low voltage.

Check voltage.

Sustained high discharge pressure.

Check running amperage and conditions described under ‘Low suction

pressure’ symptoms.

High suction and discharge pressures.

Check thermal expansion valve setting; check for air in system.

Defective compressor overload.

If compressor is hot, allow compressor to cool for two hours. Recheck for

open circuit.

Improper refrigerant charge.

Check subcooling.

Improperly wired.

Review wiring schematics.

Loose wiring.

Check all connections and wires.

Defective start relay.

Replace relay.

Motor windings damaged.

Verify amp draw.

"Compressor

hums, but will not

start."

Improperly wired.

Review wiring schematics.

Low line voltage.

Check voltage.

Loose wiring.

Check all connections.

Defective start or run capacitor.

Check run capacitor for compressor and fan motor.

Defective relay start.

Replace relay.

Motor winding damaged.

Verify amp draws.

Internal compressor mechanical damage.

Replace.

"Compressor noisy

or vibrating"

Refrigerant overcharge.

Check pressures and subcooling.

Liquid floodback.

Check thermal expansion valve setting. Check for refrigerant overcharge.

Tubing rattle.

Dampen tubing vibration by taping or clamping. Carefully bend tubing away

from contact where possible.

Scroll compressor rotating in reverse (3 phase). Rewire for opposite rotation.

Worn or damaged compressor.

Replace the compressor.

Improper mounting on unit base.

Check that compressor is properly isolated.

"High suction

pressure"

Excessive load on evaporator coil.

Check for high entering wet bulb temperature. Check for excessive air.

Compressor is unloaded.

Check head pressure, check thermal expansion valve if not functioning

properly, check pressure drop across filter drier.