0 maintenance and service, 1 maintenance schedule, 2 maintenance procedures – Reznor ZQYRA Unit Installation Manual User Manual

Page 62: Warning, 3 inlet and return air filters, 4 energy recovery wheel, Check wheel rpm, Wheel maintenance

Form I-ZQYRA P/N 260414R5, Page 62

10.0 Maintenance

and Service

10.1 Maintenance Schedule

Perform all of the procedures in Paragraph 10.2 at least once a year or more frequently

if the installation requires it.

10.2 Maintenance

Procedures

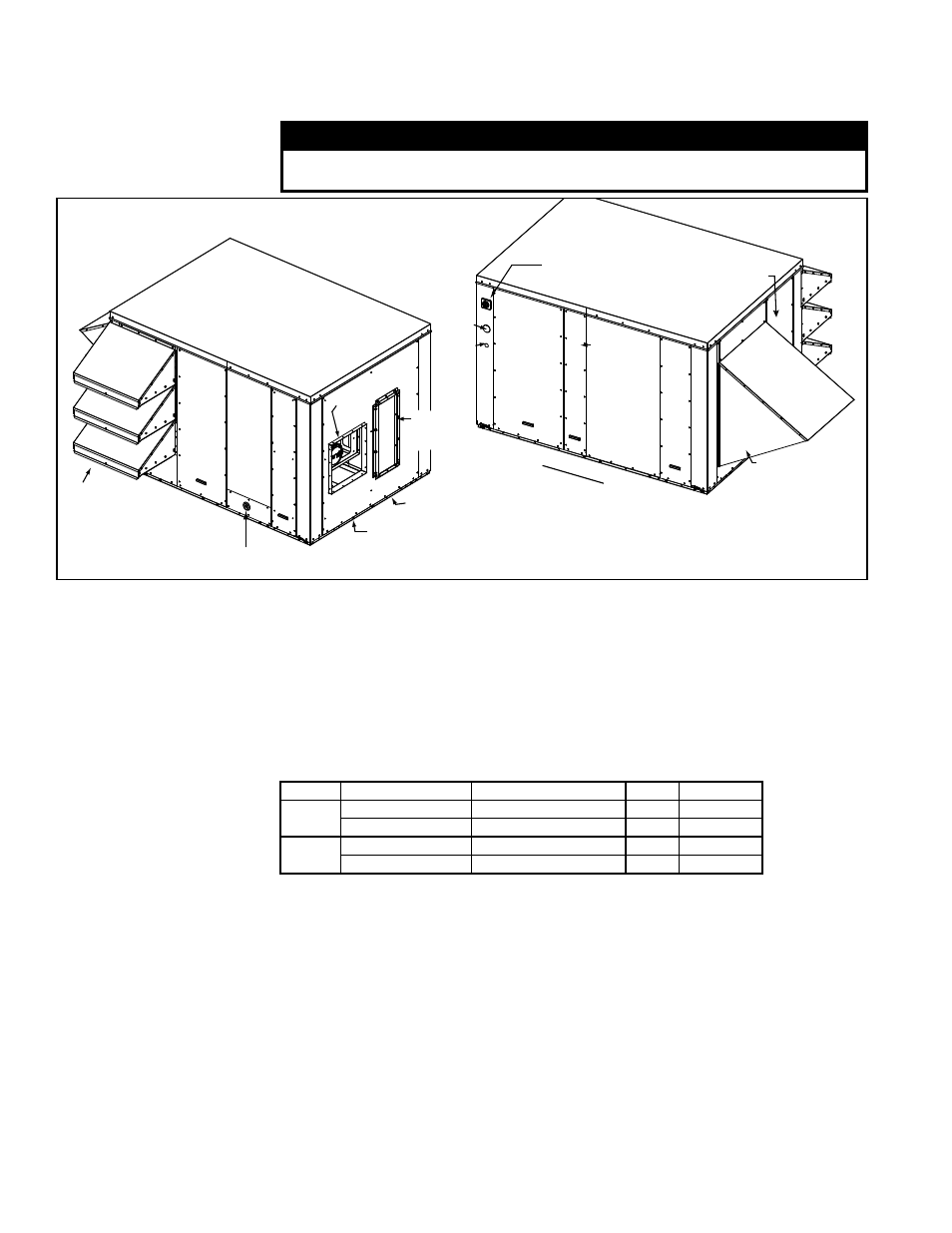

Inlet Air Hoods

with Filters -

Clean filters

(See Paragraph 6.2.3.

Size 8 - 2 filters;

Size 12 - 3 filters).

Condensate Drain Connection -

Clean drain pan and trap.

Vertical Discharge Air

Opening (In the bottom)

Vertical Return Air Opening

(in the bottom)

Inlet

Side

Post

Supply

Fan Access

Inlet

Hoods

Exhaust Hood -

Clean filter and

optional damper

blades.

Disconnect Switch (Optional)

- Lock during maintenance

and service.

Control

Access - See

FIGURE 16,

page 16.

Compressor

Access

Electric Heat (Optional)

High

Voltage

Entrance

Low

Voltage

Entrance

Exhaust

Fan Access

Horizontal

Supply

Air

Horizontal

Return Air

Opening

(Control Side

)

Return Air

Filter Access

Inlet Air

Filter Access

Enthalpy

Wheel Access

Control

Side

Post

FIGURE 32 - Access Locations for Maintenance

Procedure

WARNING

Turn off the power and lock the disconnect switch before performing

maintenance or service.

10.2.1 Inlet and

Exhaust Hoods

10.2.2 Inlet and

Exhaust Fans

Fan motors are permanently lubricated; lubrication is not required. Carefully remove

any accumulation of dirt and grease.

If equipped with an Option A23 fan selection, the exhaust fan motor is belt driven.

Check the condition and tension of the belt. Belt tension should allow a 1/2” depression

of the belt. If the belt needs to be replaced, use a factory-authorized replacement.

Remove (See Paragraph 6.2.3) and clean the filters. If equipped, clean the screen.

Remove all dirt that will obstruct airflow. If there are optional dampers, carefully remove

dirt from the blades.

10.2.3 Inlet and

Return Air Filters

Size

Location

Filter Type and Size

Qty

P/N

8

Inlet Air Filters

Pleated 16x20x2

2

104110

Return Air Filter

Pleated 16x20x2

1

104110

12

Inlet Air Filters

Pleated 16x20x2

2

104110

Return Air Filter

Pleated 16x25x2

1

104112

Check inlet and return air filters. Replace as needed.

Check Wheel RPM

The wheel should rotate approximately five rotations in 15 seconds. If rotation is

not normal, see the wheel maintenance information that follows. Perform service as

needed and/or replace any defective parts.

Wheel Maintenance

The energy recovery wheel cassette is designed to be slid out of the unit for inspection

and cleaning. Follow the instructions in

FIGURE 33 and cleaning instructions below.

How often the wheel needs to be cleaned depends on its environment. Because the

wheel rotates between two opposing airstreams, it is self-cleaning of most dry dirt and

dust and will remain efficient for a long period of time. However, when the wheel is

exposed to oils, tars, or greases in either the supply or exhaust airstream, the surface

will become “sticky” and will hold the dirt and dust. Over time the air passages will

become blocked causing loss of recovery, excessive pressure drop, and loss of energy

savings.

10.2.4 Energy

Recovery Wheel