2 energy recovery (enthalpy) wheel, 3 heat pump (r-410a refrigerant), Figure 18b - heat pump compressor and piping – Reznor ZQYRA Unit Installation Manual User Manual

Page 17

Form I-ZQYRA P/N 260414R5, Page 17

7.4.2 Energy

Recovery (enthalpy)

Wheel

The energy recovery wheel is equipped with a motor and belt drive. When the unit

controller requires energy recovery, the wheel motor responds and rotates the wheel

through both the inlet and return airstreams.

7.4.3 Heat Pump

(R-410A Refrigerant)

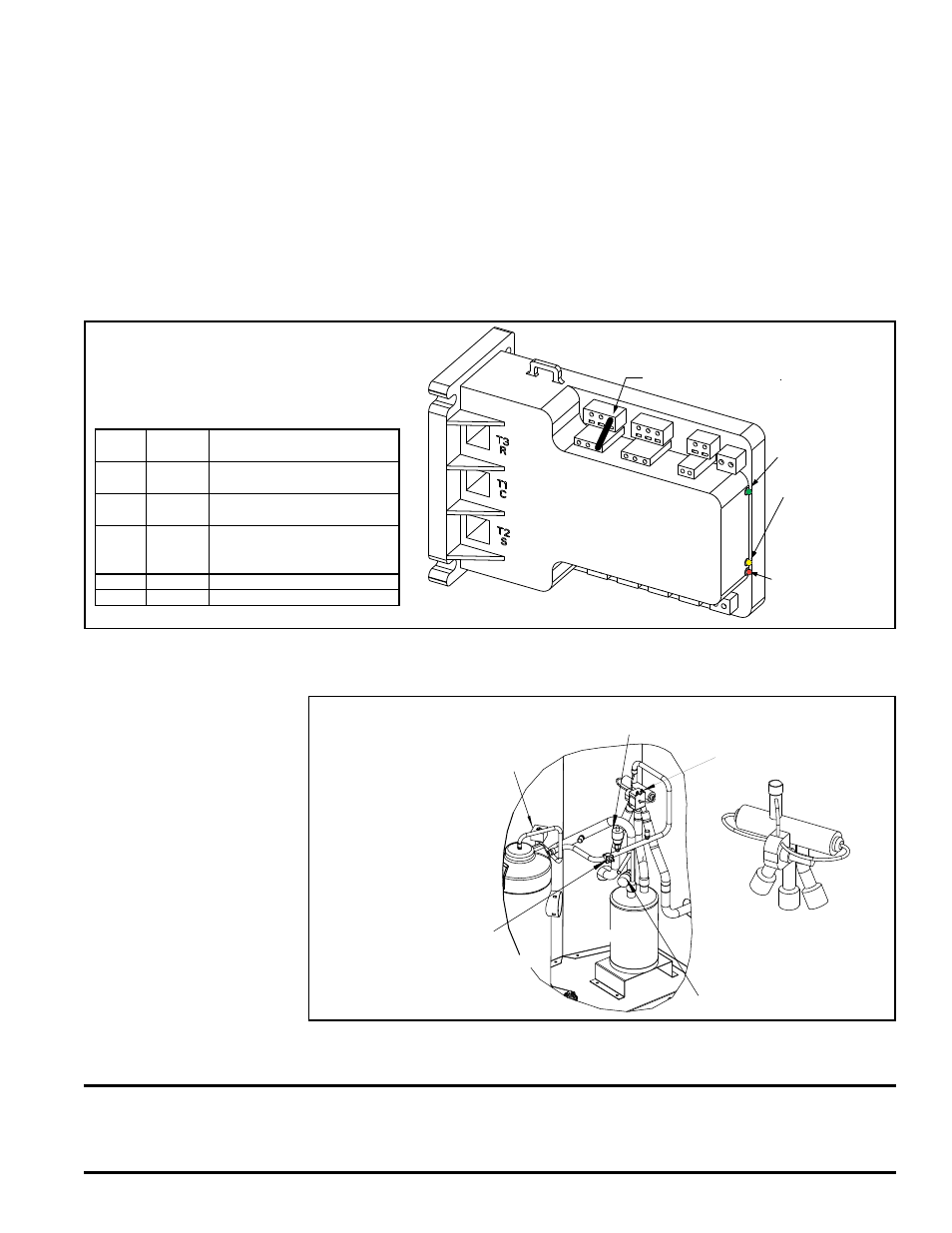

Compressor - The heat pump has a digital scroll compressor providing quieter, more

efficient operation. The compressor has high and low pressure switches, a crankcase

heater, a thermistor to protect against too high temperature, and a modulating solenoid

valve for operation. The digital controller in the electrical compartment (See

FIGURES

18A and 19.) is the electronic interface between the compressor and the system con-

troller. The compressor controller is connected to the unit control to provide protection

and diagnostics for compressor operation.

After a compressor shutdown, a two-minute anti-short cycle timer in the compressor

controller delays the compressor restart. The unit controller has a five-minute com-

pressor on/off time. The delay times are concurrent so total delay time is five minutes.

Power Light

(Green LED)

Compressor

Modulating

Solenoid Valve

Energized Light

(Yellow LED)

Alarm Light

(Red LED) - See

Paragraph 10.3.2.

Compressor Digital

Controller for

Modulating Operation

M1

A1 A2

L1 L2

U2

U1

M2

V1 V2

P6

P5 P4

P3 P2

P1

C2

C1

C4

C3

24

VAC

24

COM

T6

T5 T4

T3 T2

T1

560K OHM Resistor

between T1 & T2

FIGURE 18A - Compressor Digital

Controller located in the control

compartment interfaces the

compressor with the unit controller.

LED

Color

LED

State

Indicates

Green Solid

Power (24VAC present at

power terminals)

Green Flashing Anti-short cycle timer is

active

Yellow Solid

Unloader (Solenoid valve

is energized; compressor

capacity is 0.)

Red

Not lit

No abnormal operation alerts

Red

Flashing See Paragraph 10.3.2.

The heat pump compressor and refrigerant piping with reversing valve shown in

FIG-

URE 18B are located directly under the control compartment and are accessed through

the same removable side panel.

Thermistor

Low Pressure Switch (auto

reset) is on the suction line.

High Pressure Switch (manual

reset) is on the discharge line.

Reversing Valve

(enlarged view below)

Compressor

Modulating

Solenoid Valve

Compressor

Accumulator

When the controller calls

for heat, the valve reverses

refrigerant flow.

FIGURE 18B -

Heat Pump

Compressor

and Piping

The scroll compressor also has a belly band crankcase heater which straps around the

bottom half of the compressor. The crankcase heater must be allowed to warm up for

at least 24 hours prior to startup or after an 8-hour power outage.

Crankcase Heater

CAUTION: Crankcase heater must be allowed to warm up for at least 24 hours prior to startup

or after a power outage of eight or more hours. Either turn the unit off with a CN option switch if

available or remove the jumper to break contact between Terminals 3 and 8, BEFORE turning on

power to warm up the crankcase heater.