5 heat pump maintenance – Reznor ZQYRA Unit Installation Manual User Manual

Page 65

Form I-ZQYRA P/N 260414R5, Page 65

Compressor - The scroll compressor has a digital controller (Paragraph 7.4.3) that

interfaces the system controller and compressor operation. The controller has its own

alarm system; see the Troubleshooting Chart in Paragraph 10.3.2.

Checking Subcooling and Superheat - At startup and during service, checking sub-

cooling and superheat is required to verify proper operation of the thermal expansion

valve and refrigerant charge.

10.2.5 Heat Pump

Maintenance

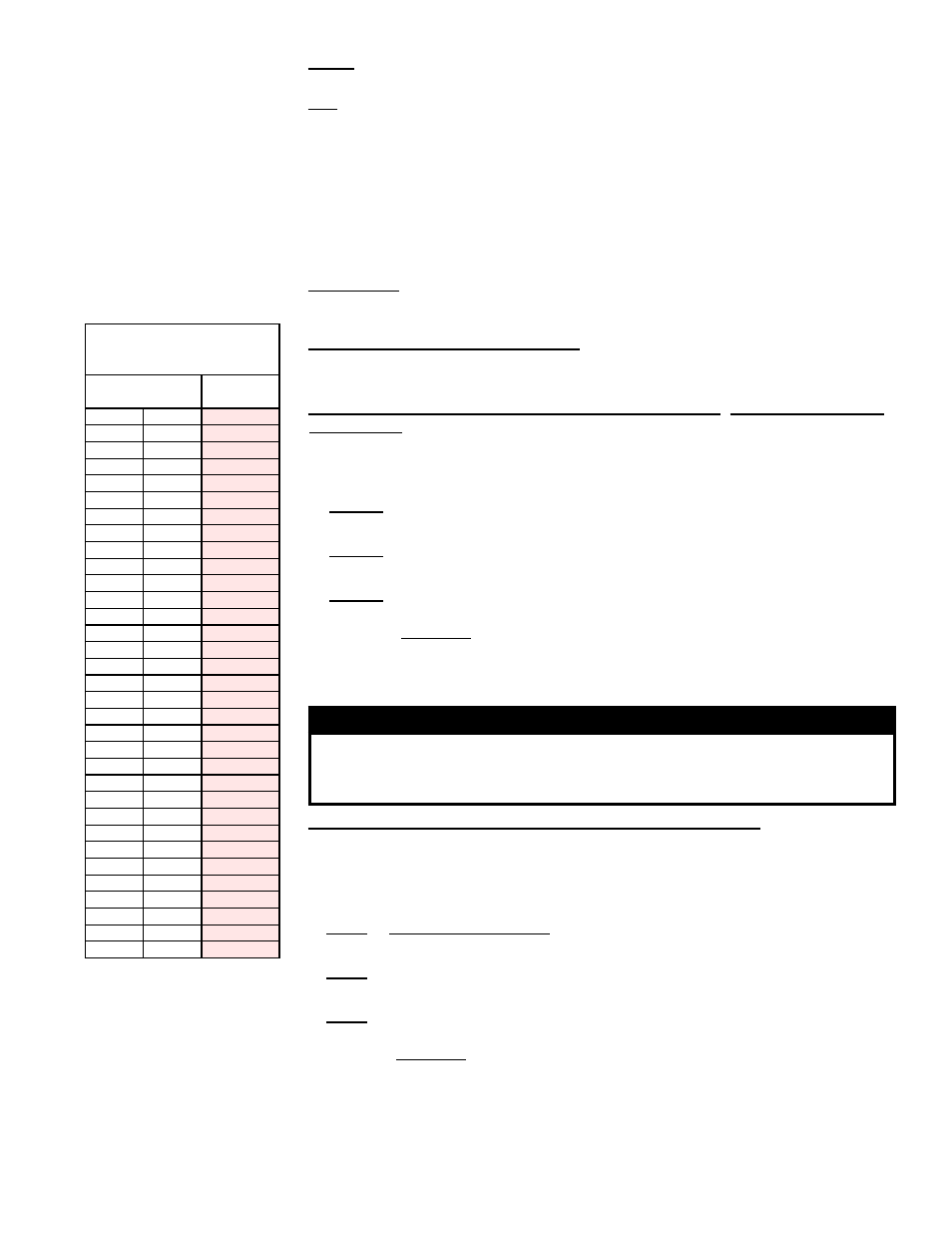

Instructions for Checking and Adjusting the Subcooling (applies to COOLING

MODE ONLY) - Acceptable subcooling readings range from 10° to 14°F (5.5° to

7.8°C).

Measure and record temperature and pressure of the liquid line at the condenser coil

outlet.

STEP 1) Record Measurements: Temperature = ________°F (°C) and Pressure =

________ psig

STEP 2) From Temperature/Pressure Conversion Chart (left), convert

Measured Pressure (STEP 1) to ________°F (°C)

STEP 3) Subtract Measured Temperature (STEP 1) from Temperature from

Conversion Chart (STEP 2) _______°F (°C) - ________°F (°C) =

________°F (°C) degrees of Subcooling

Too much subcooling indicates a refrigerant overcharge. To reduce the subcooling,

remove excess refrigerant. Too little subcooling indicates a refrigerant undercharge. To

increase subcooling, slowly add R-410A refrigerant.

WARNING

Do not release refrigerant to the atmosphere. When adding or

removing refrigerant, the qualified technician must comply with

all national, state/province, and local laws.

Instructions for Checking and Adjusting the Superheat (applies to both

COOLING AND HEATING MODE) - Superheat should be in the 8° to 12°F

(4.5° to 6.7°C) range.

Measure and record temperature (insulate probe from surrounding air

temperature) and pressure in the suction line at the compressor inlet.

STEP 1) Record Measurements: Temperature = _______°F (°C) and Pressure =

_______ psig

STEP 2) From Temperature/Pressure Conversion Chart (left), convert

Measured Pressure (STEP 1) to _______°F (°C)

STEP 3) Subtract Measured Temperature (STEP 1) from Temperature from

Conversion Table (STEP 2) _______°F (°C) - ________°F (°C) =

________°F (°C) degrees of Superheat

Typically too much superheat indicates that the evaporator coil is undercharged.

Too little superheat typically indicates that the evaporator coil is overcharged and

may potentially flood liquid refrigerant to the compressor. To reduce the superheat,

adjust the thermal expansion valve by turning the adjusting stem counterclockwise. To

increase the superheat, adjust the thermal expansion valve by turning the adjusting

stem clockwise.

Pressure/Temperature Chart

for Checking Superheat &

Subcooling

Saturation

Temperature

Pressure

(psig)

(°F)

(°C)

R410A

0

-17.8

48.2

5

-15.0

55.0

10

-12.2

62.3

15

-9.4

70.2

20

-6.7

78.7

25

-3.9

87.8

30

-1.1

97.5

35

1.7

107.9

40

4.4

118.9

45

7.2

130.7

50

10.0

143.3

55

12.8

156.6

60

15.6

170.7

65

18.3

185.7

70

21.1

201.5

75

23.9

218.2

80

26.7

235.9

85

29.4

254.6

90

32.2

274.3

95

35.0

295.0

100

37.8

316.9

105

40.6

339.9

110

43.3

364.1

115

46.1

389.6

120

48.9

416.4

125

51.7

444.5

130

54.4

474.0

135

57.2

505.0

140

60.0

537.6

145

62.8

571.7

150

65.6

607.6

155

68.3

645.2

NOTE: Information in the pressure/

temperature chart was taken

from the Temperature Pressure

Chart printed in Form IC-2-04

by the Sporlan Valve Company,

Washington, MO 63090.

Pulley - the pulley is secured to the drive motor shaft by a set screw. The set screw is

secured with removable Locktite to prevent loosening. Confirm the set screw is secure.

Belt - The belt is of urethane stretch material and is designed to provide constant ten-

sion. There is no type of adjustment. Inspect the belt for proper tracking and tension. If

a belt needs replaced, it must be replaced with a factory-authorized replacement (Size

8,

P/N 262488; Size 12, P/N 262489). Follow the wheel manufacturer’s instructions.

NOTE: A properly tensioned belt will turn the wheel immediately after power is applied with no visible slippage during

startup. The belt should track approximately 1/4” from the outer edge of the rim.

If the belt or any other component needs replaced, use only factory-authorized replacement designed for the purpose.

Follow instructions provided by the wheel manufacturer.