0 maintenance and service (cont’d), 2 maintenance procedures (cont’d) – Reznor ZQYRA Unit Installation Manual User Manual

Page 64

Form I-ZQYRA P/N 260414R5, Page 64

WARNING

Weight of the installed segments will cause

the wheel to accelerate in rotation. Failure

to maintain control of the wheel rotation

while re-installing all segments could

cause severe injury to fingers or hand

caught between revolving spokes and the

bearing support beam. Insert the handle of

a hammer or other such tool through the

spokes above or below the bearing support

as a stop to limit rotation of an unbalanced

wheel.

Position one segment opening at the top of the

cassette. Insert a “stop” (see warning above) to hold

the wheel in place. Unlock and open the segment

retaining brackets on both sides of the opening.

Position a clean segment with the imbedded

stiffeners toward the motor side of the wheel.

Holding the segment as vertically as possible and

centered between the spokes, insert the nose of

the segment downward between the hub plates.

Ease the segment down until its outer rim clears the

inside of the wheel rim and press it inward against

the spoke flanges. Close and latch the retaining

brackets. Make sure each retaining bracket is fully

engaged under the catch.

b. Remove the stop and slowly rotate the installed

segment to the bottom of the wheel. Re-insert the

stop and repeat the procedure to put a segment in

the top position. Continue the procedure, balancing

the wheel by installing opposite segments, until all

of the segments are in place.

c. While the wheel cassette is out, follow the

instructions below to check the seals and the drive

components.

d. After all wheel maintenance is complete, position

the wheel supports (See

FIGURE 32.) on the top

and bottom of the cassette and carefully slide all

three pieces back into the cabinet. Being sure the

cassette is positioned properly, replace the blockoff

panel. Re-connect the motor wire.

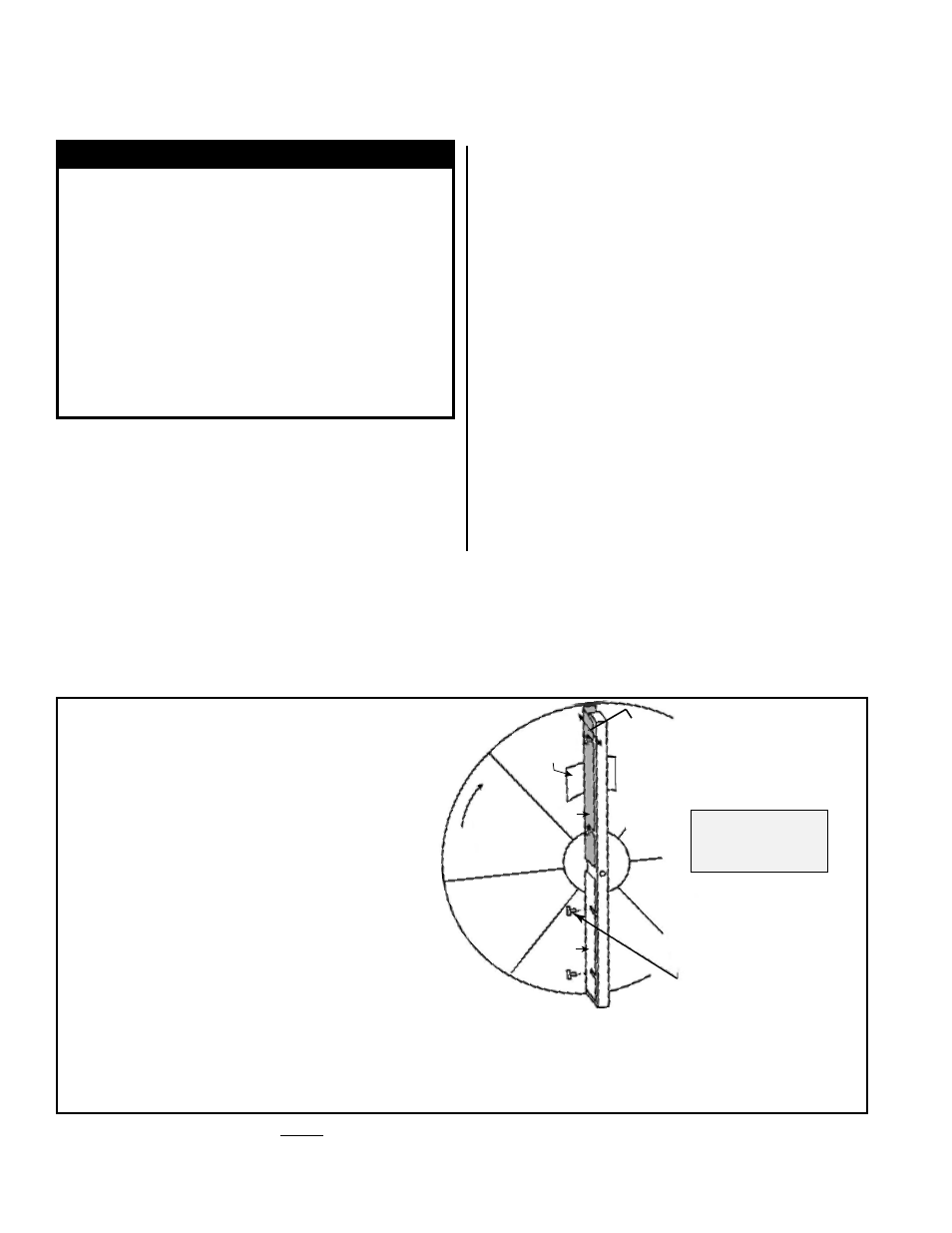

Checking the Wheel

Seals (FIGURE 34)

The seals are on the center support that goes across the diameter of the wheel. There

are two seals on each side of the wheel with one seal on each side of the hub. Seals

are metal strips with insulation on the surface closest to the wheel. The purpose of the

seals is to minimize the transfer of air between the counter flowing airstreams.

After any wheel service and during maintenance, check the seal adjustment. Adjusting

the seals will require a screwdriver and a piece of paper.

Wheel

Rotation

Folded Paper

Feeler Gauge

Adjusting Screws

(Only loosen when adjusting

seal; do not remove.)

Slide seal (shown in gray) toward wheel

until a slight friction on the feeler gauge

is detected when gauge is moved along the

length of a spoke. Repeat with all seals.

Seal

Repeat the same

adjustment procedure

to the two seals on the

other side of the wheel.

Seal

FIGURE 34 - Adjust Seals on the Energy

Recovery Wheel

1. If the wheel has not been removed from the

cabinet, follow steps in

FIGURE 33.

2. Each seal strip has adjustable retaining screws

that allow the insulation to move toward or away

from the wheel. Refer to

the illustration and

follow the instructions below to adjust the

seals.

a) On one seal, loosen the seal retaining screws

just enough to slide the seal strip.

b) Fold the piece of paper to use as a feeler

gauge. Position the folded paper between the

wheel surface and the seal. Turn the wheel so

that the seal is lined up with a segment spoke.

c) Adjust the seal toward the wheel surface and

slide the feeler gauge (folded paper) along the

length of the spoke. When a slight friction is

detected on the feeler gauge (folded paper),

tighten the screws. Recheck the clearance

with the feeler gauge.

d) Repeat the procedure on the other three seals.

3. When the unit is started, start and stop the wheel several

times to verify seal adjustment and to confirm that the

belt is tracking properly on the wheel rim. The belt should

be approximately 1/4” from the outer edge of the rim.

10.0 Maintenance

and Service

(cont’d)

10.2 Maintenance Procedures (cont’d)

10.2.4 Energy Recovery Wheel (cont’d)

Checking Wheel Drive

Components

Instructions (cont’d)

Motor - The motor bearings are pre-lubricated and do not need additional lubrication.

Clean any dirt from the air cooling ports in the motor housing.