0 electrical connections and wiring – Reznor ZQYRA Unit Installation Manual User Manual

Page 14

Form I-ZQYRA P/N 260414R5, Page 14

7.0 Electrical

Connections

and Wiring

All electrical wiring and connections, including electrical grounding MUST be made

in accordance with the National Electric Code ANSI/NFPA No. 70 (latest edition). In

addition, the installer should be aware of any local ordinances or electric company

requirements that might apply.

See

FIGURE 1, page 4, to show the entrance locations for the high voltage and low

voltage wiring.

7.1 Supply Voltage

Check the rating plate for the supply voltage and current requirements. The electric

supply to the unit must meet stringent requirements for the system to operate properly.

Voltage supply should be within ±10% or as stated on the rating plate. Maximum imbal-

ance on a 3-phase system is 2%. Follow instructions below to check.

CAUTION: If this

unit is allowed

to operate on an

electric supply

that is not within

the specified

tolerances, the

product warranty

shall be void. See

Hazard Levels,

page 2.

Disconnect Switch

The system may be factory equipped with a built-in non-fusible, lockable disconnect

switch (See location in

FIGURE 1, page 4). The built-in disconnect switch (Option BA6)

requires copper wiring with ampacity based on 75°C maximum temperature rating at

the line side terminals.

If the system does not have a built-in disconnect switch, a field-provided or optional

shipped-separate, wall-mounted disconnect switch is required. It is recommended that

there is at least four feet (1.2M) of service room between the wall-mounted switch and

unit access panels. All external wiring must be within approved conduit and have a

minimum temperature rise rating of 60°C. Run conduit so that it does not interfere with

unit access panels. When providing or replacing fuses in a fusible disconnect, use dual

element time delay fuses and size according to the rating plate.

If the power supply is not within these tolerances, contact the power company prior to

operating the system.

Check Voltage Supply - See voltage use range on the rating plate. Measure (and

record) each supply leg voltage at all line disconnect switches. Readings must fall

within the allowable range.

Check Voltage Imbalance - In a 3-phase system, excessive voltage imbalance

between phases will cause compressor motors to overheat and eventually fail. Maxi-

mum allowable imbalance is 2%. To determine voltage imbalance, use recorded volt-

age measurements taken above in the following formula.

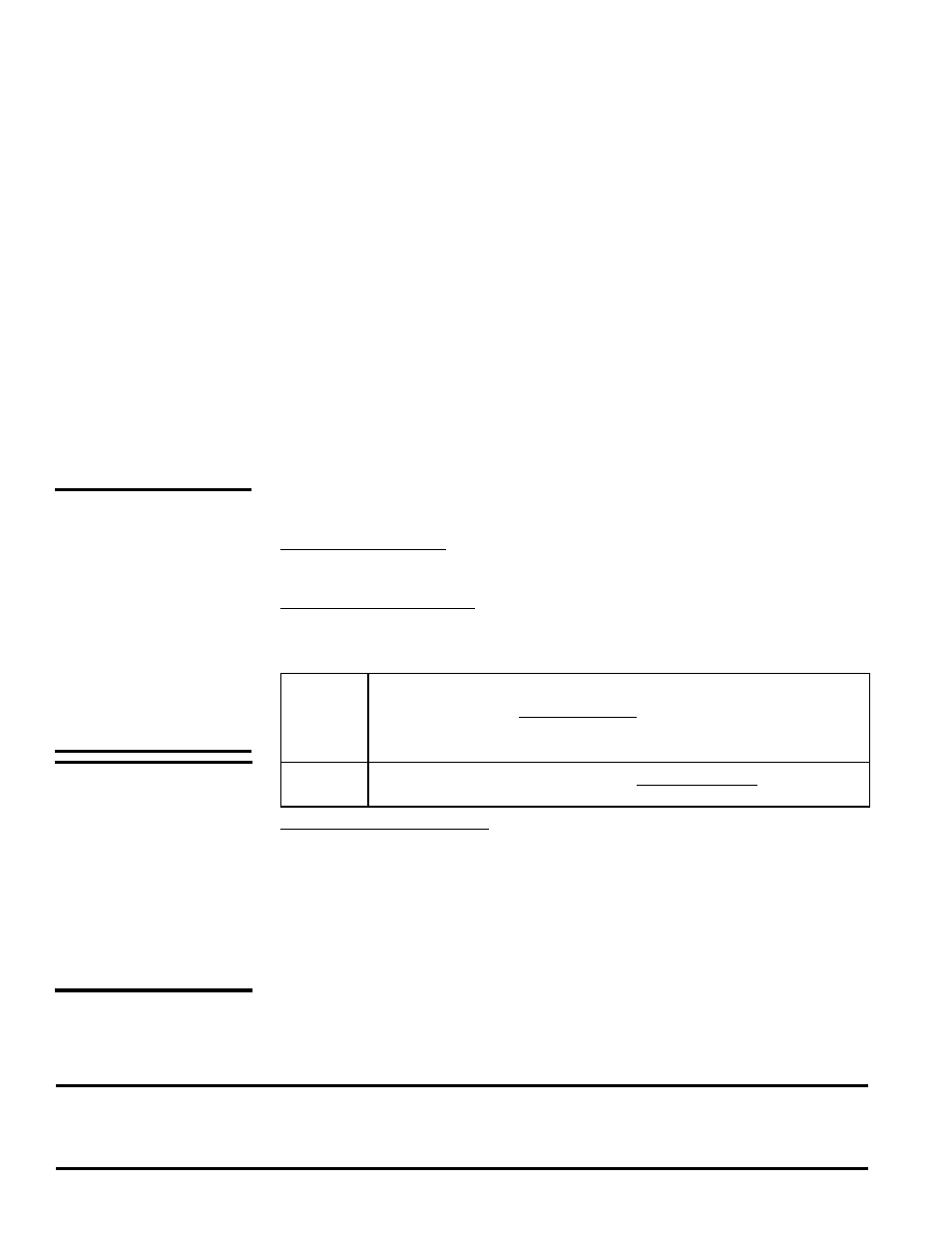

Key:

V1, V2, V3 = line voltages as measured

VA (average) =

(V1 + V2 + V3)

3

VD = line voltage (V1, V2, or V3) that deviates farthest from average (VA)

Formula:

% Line Voltage Imbalance =

[100 x (VA - VD)]

VA

3-Phase Wiring Connection - There is a chance of unknowingly connecting

3-phase power in such a way as to cause compressor rotation in reverse. To

prevent damage to the components, it is important to check this on startup.

Checking the rotation of the compressor requires connecting pressure gauges

BEFORE startup. Connect refrigerant manifold pressure gauges rated for use with

R410-A refrigerant to the compressor suction and discharge lines.

At startup, observe the gauges.

If the suction pressure rises and discharge pres-

sure drops, the compressor is operating in reverse and should be shut down.

(After several minutes of operation in reverse, the compressor’s internal protector will

trip. If compressors are repeatedly allowed to restart and run in reverse, the compres-

sors will be permanently damaged.)

To correct, shut down the unit and turn off the power. At the incoming power con-

nection, switch the 3-phase line voltage wiring connections before restarting the unit.

Recheck the pressure gauges.

CAUTION: Check

compressor

rotation to verify

correct phasing.

DO NOT use fan

rotation to check

phasing. ECM

fans cannot run

backwards.

CAUTION: Connect pressure gauges to the suction and discharge lines BEFORE

startup so that compressor rotation can be checked immediately. Scroll compressors

will be destroyed if operated in the wrong direction. See Hazard Levels, page 2.